Process for reducing and extracting iron from high-iron red mud

A high-iron red mud and process technology, applied in the field of high-iron red mud reduction and iron extraction, can solve the problems of low recovery rate of iron concentrate in magnetic separation, high energy consumption, difficult separation of iron and aluminum, etc., and achieve multi-level utilization and saving Energy and production cost reduction effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] In terms of mass percentage, the high-iron red mud used in this embodiment contains: TFe 37.57%, FeO 0.24%, SiO 2 2.97%, Al 2 o 3 13.41%, TiO 2 5.24%, Na 2 O 1.22%, K 2 O 0.15%, CaO 0.28%, MgO 0.06%, P0.02%, S 0.02%; carry out reduction iron extraction process on it, the specific steps are as follows:

[0035] S1: First dry the high-iron red mud, crush it to -1mm, add coal powder, and mix evenly to obtain a mixed material. In the mixed material, the amount of carbon in the reducing agent and oxygen in the iron oxide in the high-iron red mud The ratio is 0.8, and the exhaust gas produced by the rotary kiln is used to preheat the mixed material to 450°C;

[0036] S2: The preheated mixed material is added to the hot-pressed pelletizing device, hot-pressed and pelletized under a pressure of 45MPa, and the pressure is maintained for 1min to obtain high-iron red mud hot-pressed carbon-containing pellets with a size of 16mm×12mm×10mm. Ball type, compressive strength 72...

Embodiment 2

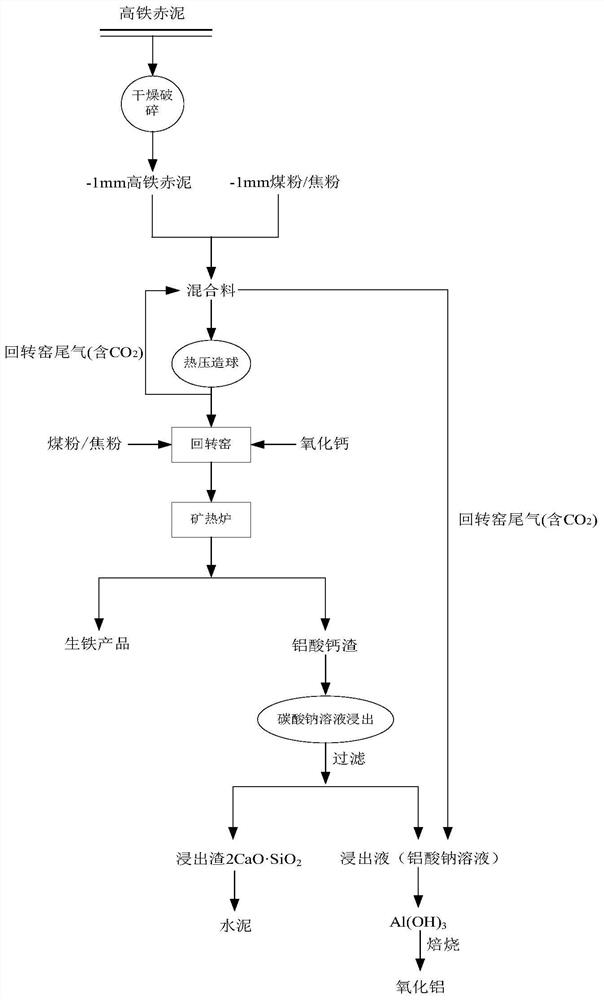

[0043] In terms of mass percentage, the high-iron red mud used in this embodiment contains: TFe 41.57%, FeO 0.55%, SiO 2 3.12%, Al 2 o 3 14.55%, TiO 2 4.24%, Na 2 O 2.12%, K 2 O 0.05%, CaO 0.20%, MgO 0.22%, P0.02%, S 0.02%, carry out hot-press pelletizing-rotary kiln roasting-submerged arc furnace smelting reduction on it as figure 1 Shown, method differs from embodiment 1 in that:

[0044] S1: The amount of pulverized coal is added so that in the mixed material, the ratio of the amount of carbon in the reducing agent to the amount of oxygen in the iron oxide in the high-iron red mud is 0.9, and the tail gas produced by the rotary kiln preheats the mixed material to 470 °C;

[0045] S2: hot-press pelletizing under a pressure of 40MPa, maintain the pressure for 1.5min, and the compressive strength of hot-pressed carbon-containing pellets is 675N / piece;

[0046] S3: The amount of pulverized coal added is 10% of the mass of high-iron red mud, and the rotary kiln is roaste...

Embodiment 3

[0051] In terms of mass percentage, the high-iron red mud used in this embodiment contains: TFe 38.52%, FeO 0.48%, SiO 2 2.12%, Al 2 o 3 15.00%, TiO 2 3.24%, Na 2 O 1.45%, K 2 O 0.56%, CaO 0.33%, MgO 0.45%, P0.02%, S 0.02%, carry out hot-press pelletizing-rotary kiln roasting-submerged arc furnace smelting reduction on it as figure 1 Shown, method differs from embodiment 1 in that:

[0052] S1: The tail gas produced by the rotary kiln preheats the mixed material to 500°C;

[0053] S2: Hot-press pelletizing under a pressure of 35MPa, maintain the pressure for 2 minutes, and the compressive strength of hot-pressed carbon-containing pellets is 665N / piece;

[0054] S3: Calcium oxide and Al in high-iron red mud carbonaceous pellets 2 o 3 The content is based on n(CaO) / n(Al 2 o 3 ) is added at a ratio of 2.0;

[0055] S4: Obtain a pig iron product containing 93.55% iron by mass and a 93.10% iron recovery rate;

[0056] S5: Use a sodium carbonate solution with a concent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com