High-toughness multiphase ceramic material as well as preparation method and application thereof

A technology of composite phase ceramics and high toughness, which is applied in the direction of metal material coating process, coating, fusion spraying, etc., can solve the problems of low fracture toughness, short service life and low reliability of thermal barrier coatings, and achieve low thermal conductivity, high fracture toughness, and high density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] A method for preparing a high-toughness composite ceramic material, comprising the following steps:

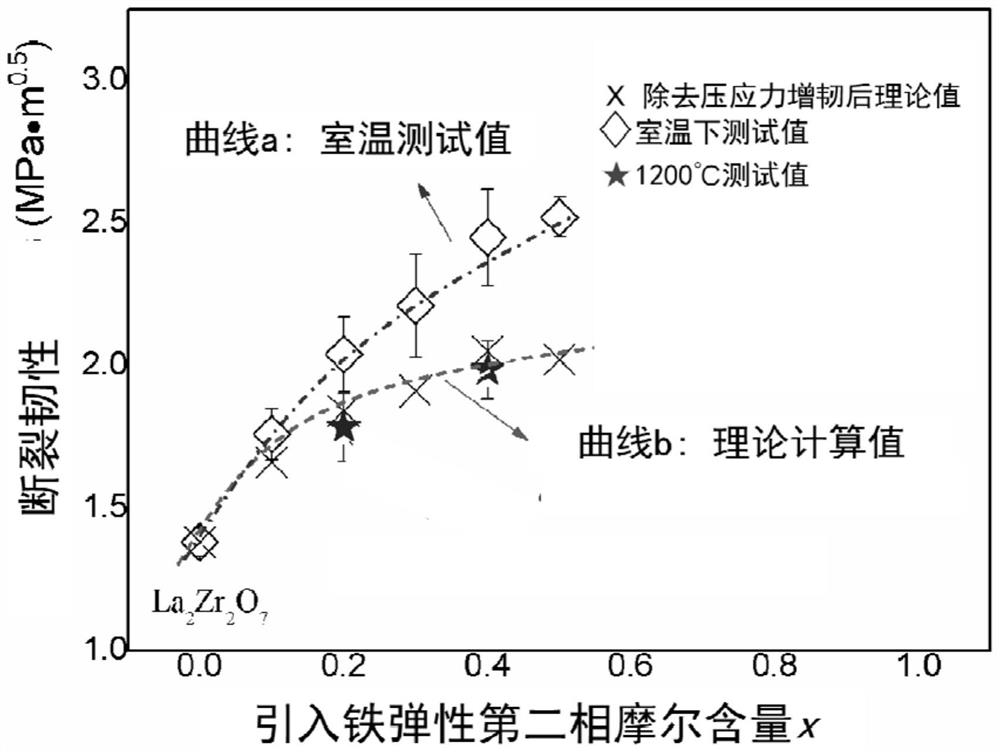

[0037] (1) Combine lanthanum zirconate powder and neodymium aluminate (NdAlO) with a particle size not exceeding 5 μm 3 ) powders are mixed according to the molar ratio of x:(1-x); wherein, the value of x is 0.1; NdAlO 3 The Curie temperature is 1367°C;

[0038] (2) Add the mixed powder into a ball mill tank, and ball mill at a speed of 200-450 rpm for 5-24 hours to obtain a mixed slurry with a particle size of 1-5 μm;

[0039] (3) Spray-dry the above mixed slurry at 80-100° C. for 2-4 hours to obtain a spherical powder with a particle size of 20-40 μm. The powder is put into a mold with a diameter of 40mm, and spark plasma sintering is carried out. The sintering process is as follows: the temperature is raised to the sintering temperature of 1500-1600°C at a heating rate of 100-120K / min, and the temperature is kept at a pressure of 30-50MPa for 5-15min, that is, a c...

Embodiment 2-5

[0041] The main difference between Examples 2-5 and Example 1 is that the values of x are respectively 0.2, 0.3, 0.4, and 0.5, and the others are the same as in Example 1 to obtain xNdAlO 3 / (1-x)La 2 Zr 2 o 7 Composite ceramics.

Embodiment 6

[0043] A method for preparing a high-toughness composite ceramic material, comprising the following steps:

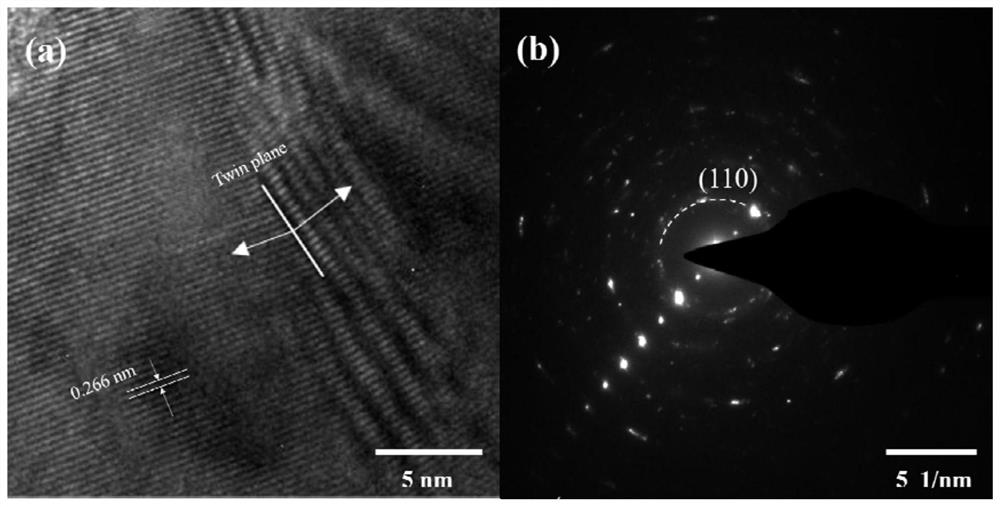

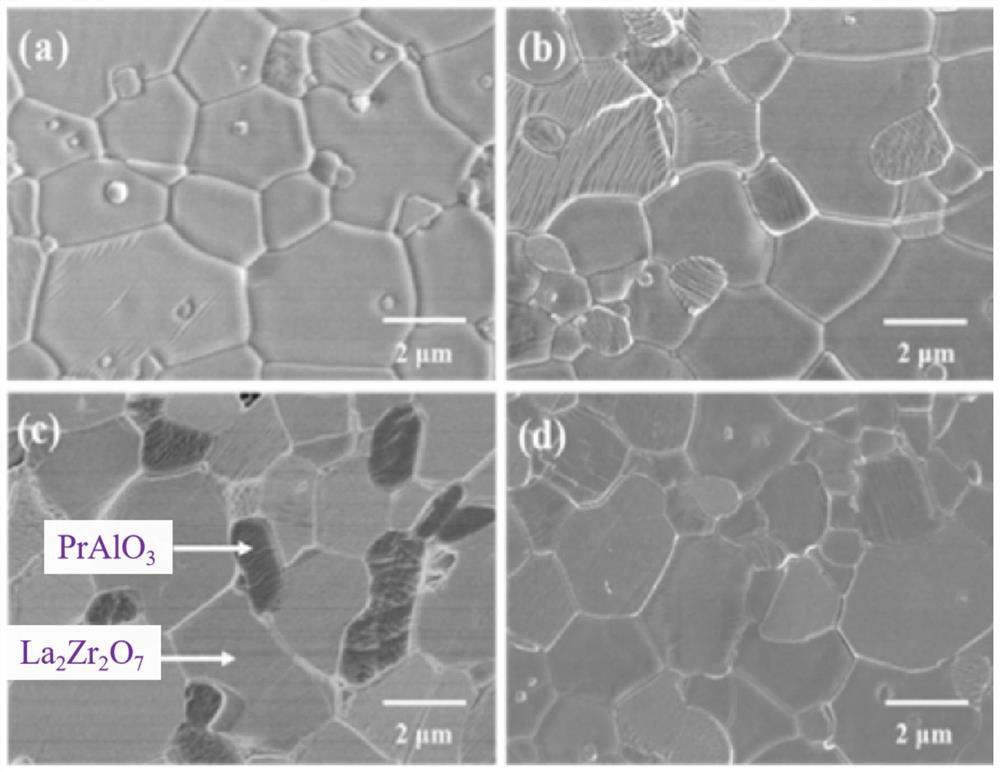

[0044] (1) Combine lanthanum zirconate powder and praseodymium aluminate (PrAlO 3 ) powder is mixed according to the molar ratio of x:(1-x); wherein, the value of x is 0.2; praseodymium aluminate (PrAlO 3 ) has a Curie temperature of 1047°C;

[0045] (2) Add the mixed powder into a ball mill tank, and ball mill at a speed of 200-450 rpm for 5-24 hours to obtain a mixed slurry with a particle size of 1-5 μm;

[0046] (3) Spray-dry the above mixed slurry at 80-100° C. for 2-4 hours to obtain a spherical powder with a particle size of 20-40 μm. The powder is put into a mold with a diameter of 40mm, and spark plasma sintering is carried out. The sintering process is as follows: the temperature is raised to the sintering temperature of 1500-1600°C at a heating rate of 100-120K / min, and the temperature is kept at a pressure of 30-50MPa for 5-15min, that is, a cylindrical b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Curie point | aaaaa | aaaaa |

| fracture toughness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com