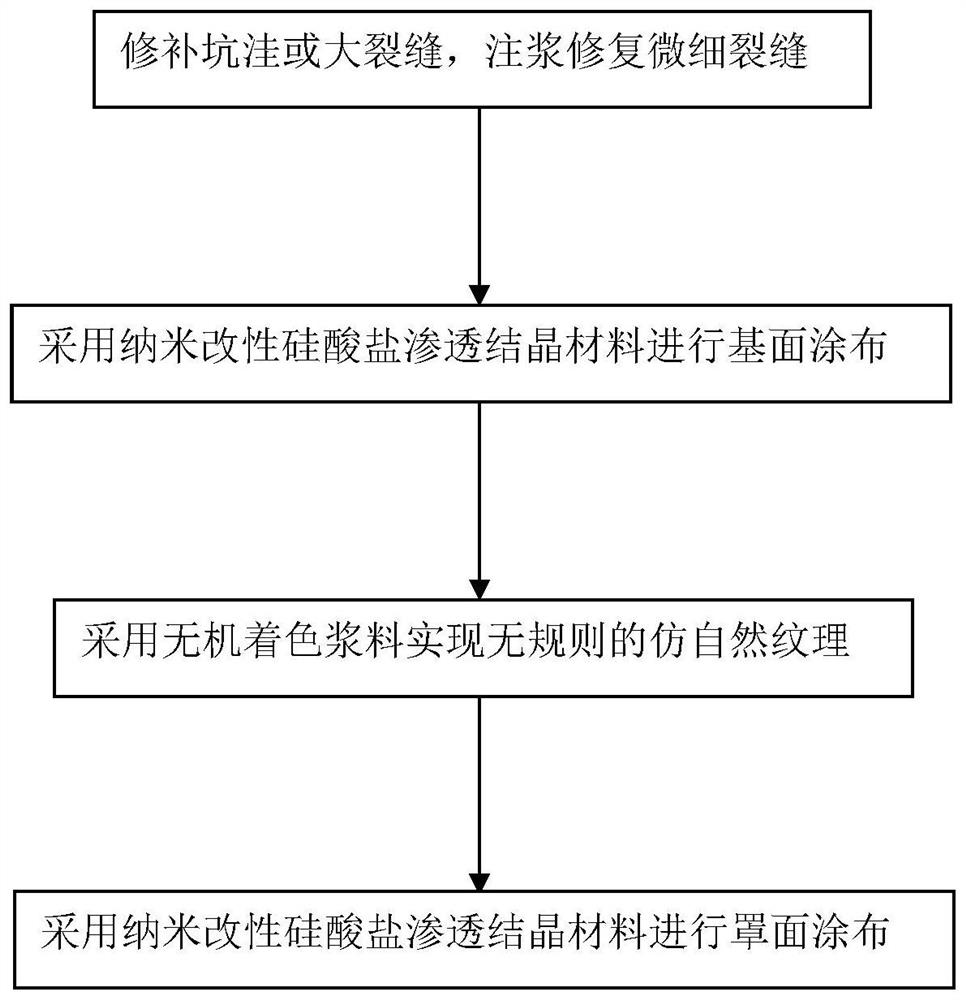

Construction method for creating fair-faced effect on concrete base surface

A construction method and concrete technology, which are applied in building structures, coatings, alkali metal silicate coatings, etc., can solve the problems of inability to maintain the decorative effect of imitation water for a long time, easy to age, fall off, etc. Simple construction process and low requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

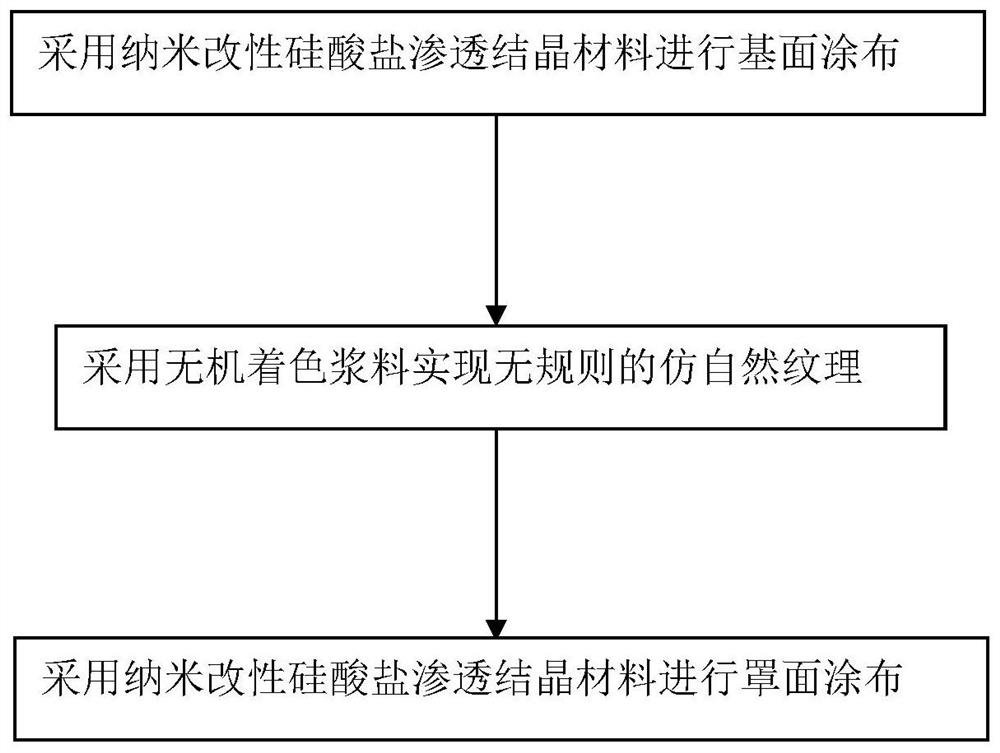

Method used

Image

Examples

Embodiment 1

[0078] The first step is to spray the base surface with nano-modified silicate infiltration crystalline material, and the spraying amount is 150ml / m 2 , Penetrate to a depth of more than 4mm on the concrete base. The preparation process of the nano-modified silicate infiltration crystalline material is as follows:

[0079] Weigh 0.07 parts of dodecyltrimethylammonia chloride, 0.15 parts of sodium borate, 0.3 parts of sodium thiosulfate, 0.15 parts of ammonium chloride, 0.2 parts of potassium carbonate, 0.15 parts of sodium metaphosphate, 0.15 parts of magnesium fluoride, amino 0.35 parts of sodium alkoxide, 65 parts of deionized water, etc., mixed and stirred in a high-speed shear kettle at a speed of 1000rpm to disperse, and added 23 parts of sodium silicate and 15 parts of potassium silicate while stirring at a high speed until the addition was complete, and the mixed solution was Completely transparent, homogeneous liquid. Among them, the nano-silica active particles have...

Embodiment 2

[0090] The first step is to spray the base surface with nano-modified silicate infiltration crystal material, and the spraying amount is 120ml / m 2 , slice analysis, so that the nano-modified silicate infiltration crystalline material penetrates to a depth of more than 4mm on the concrete base. The preparation process of the nano-modified silicate infiltration crystalline material is as follows:

[0091] Weigh 0.05 part of dodecyltrimethylammonia chloride, 0.10 part of sodium borate, 0.1 part of sodium thiosulfate, 0.10 part of ammonium chloride, 0.15 part of potassium carbonate, 0.10 part of sodium metaphosphate, 0.1 part of magnesium fluoride, amino 0.15 parts of sodium alkoxide, 63 parts of deionized water, etc., mixed and stirred in a high-speed shear kettle at a speed of 1000rpm to disperse, and added 23 parts of sodium silicate solution and 16 parts of potassium silicate solution while stirring at a high speed until completely added, and mixed The solution is completely ...

Embodiment 3

[0102] The first step is to spray the base surface with nano-modified silicate infiltration crystalline material, and the spraying amount is 200ml / m 2 , Section detection, penetration to the depth of 4mm above the concrete base. The preparation process of the nano-modified silicate infiltration crystalline material is as follows:

[0103] Weigh 0.05 part of dodecyltrimethylammonia chloride, 0.10 part of sodium borate, 0.1 part of sodium thiosulfate, 0.10 part of ammonium chloride, 0.15 part of potassium carbonate, 0.10 part of sodium metaphosphate, 0.1 part of magnesium fluoride, amino 0.15 parts of sodium alkoxide, 66 parts of deionized water, etc., mixed and stirred and dispersed in a high-speed shearing kettle with a speed of 1200rpm, and added 20 parts of sodium silicate solution and 18 parts of potassium silicate solution while stirring at a high speed until completely added, and mixed The solution is completely transparent and homogeneous liquid. Among them, the nano-s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com