Fast detection method for aluminum alloy hardenability by electro-conductibility

A technology of electrical conductivity and hardenability is applied in the field of using electrical conductivity to rapidly detect the hardenability of aluminum alloys, which can solve the problems affecting the mechanical properties of the alloy during the aging process and the hardenability of the alloy, so as to improve the heat treatment process and improve the hardenability. , detect fast and effective effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

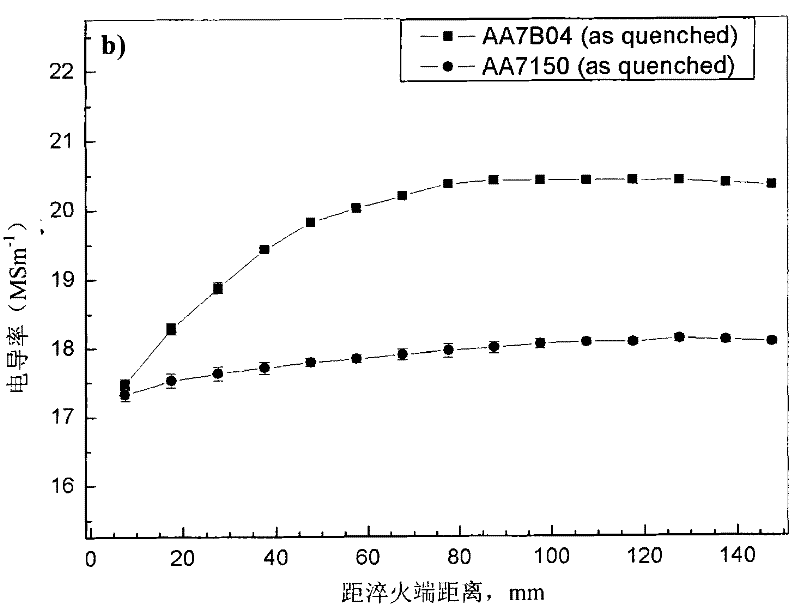

[0031] 7B04 and 7150 aluminum alloy thick plates are widely used in aircraft manufacturing, and 7150 aluminum alloy is a high-purity aluminum alloy, which is one of the preferred aluminum alloy materials in new aircrafts. safety is of great importance. For 7B04 and 7150 aluminum alloy thick plates (thicknesses are both 150mm), according to the aforementioned sampling method, take cylindrical samples with a diameter of 50mm; After solid solution for 3 hours, water quenching was carried out respectively; after the sample was cooled, the cylindrical sample was cut into 30 cylindrical slices with a height of 5mm, and the electrical conductivity was measured on the end quenching surface, the cutting surface and the uppermost end surface of the cylindrical sample. Value, and drawn into a curve; conductivity measurement in accordance with the corresponding national standards. figure 1 It is the conductivity curve of 7B04 aluminum alloy thick plate and 7150 aluminum alloy thick plate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com