Device and method for automatically powdering silicon wafer

A silicon wafer, automatic technology, applied in the direction of electrical components, electrical solid devices, semiconductor/solid device manufacturing, etc., can solve the problems of difficult control of photolithography process and complicated process, and achieve low requirements on the surface of silicon wafers, simple process, non-scratch effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

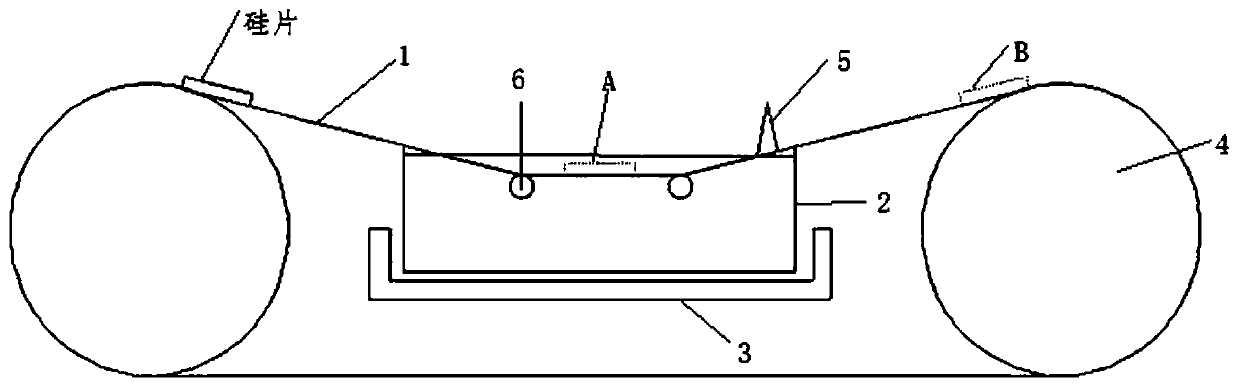

[0036] This embodiment provides a device for automatic powdering of silicon wafers, which has the following functions: figure 1 With the structure shown, the device includes: transmission equipment, powder scraper 5, and powder feeding equipment.

[0037] Wherein, the powdering equipment is used for coating the glass paste on the silicon wafer, and the powdering equipment includes an ultrasonic device 3 and a storage tank 2, the storage tank 2 is used for containing the glass paste, and the ultrasonic device 3 is used for ultrasonically treating the materials in the storage tank, Remove the air bubbles in the groove of the silicon wafer, and fill the uniform glass paste into the groove of the silicon wafer. The storage tank 2 can be arranged inside the ultrasonic device 3 , and the storage tank 2 is arranged between two rotating wheels 4 . Two pulleys 6 are arranged inside the storage tank 2, and the pulleys 6 are used to make the conveyor belt 1 pass through the glass paste....

Embodiment 2

[0051] This example provides the use of figure 1 The automatic powder feeding method that the shown device completes specifically includes:

[0052] By photolithography, the area that does not need to be grooved is protected;

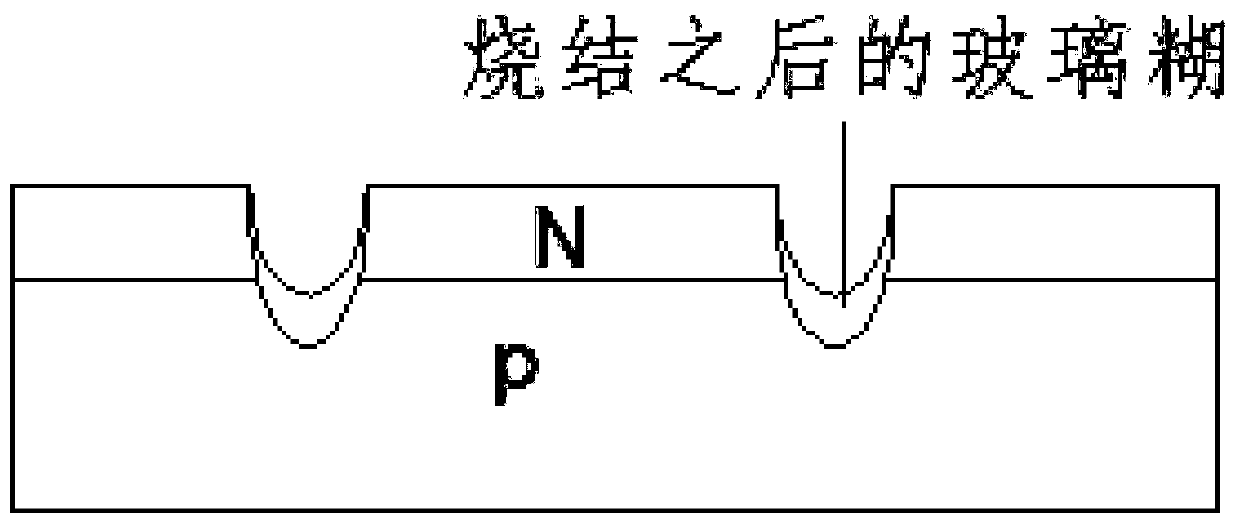

[0053] The PN junction of the silicon wafer is dug out by acid rot to form a clean PN junction section, and the acid solution is HF:HNO 3 =1:3;

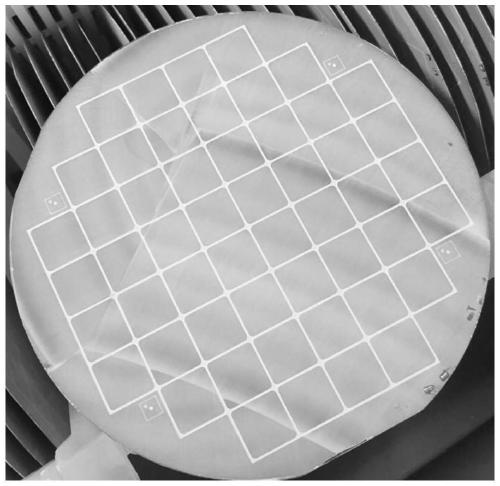

[0054] Load silicon wafers to figure 1 On the device shown, it is required that the grooves produced by corrosion form an angle of 75° with the belt running track, and the silicon wafers are fed into the glass paste (the composition of the glass paste is glass powder and butyl with a mass ratio of 3:1) through the conveyor belt. Carbitol storage tank, and at a speed of 3mm / sec, the running distance of the silicon wafer in the glass paste is 12cm, and the air bubbles in the silicon wafer groove are removed by ultrasonic waves, and the glass paste is evenly filled into the silicon wafer groove Inside, so tha...

Embodiment 3

[0060] This example provides the use of figure 1 The automatic powder feeding method completed by the shown device specifically includes:

[0061] By photolithography, the area that does not need to be grooved is protected;

[0062] The PN junction of the silicon wafer is dug out by acid rot to form a clean PN junction section, and the acid solution is HF:HNO 3 =1:3;

[0063] Load silicon wafers to figure 1 On the device shown, it is required that the grooves produced by the corrosion form an angle of 45° with the belt running track, and the silicon wafers are fed into the glass paste (the composition of the glass paste is glass powder and butyl with a mass ratio of 3:1) through the conveyor belt. Carbitol storage tank, and at a speed of 2mm / sec, the running distance of the silicon wafer in the glass paste is 12cm, and the bubbles in the silicon wafer groove are removed by ultrasonic waves, and the glass paste is evenly filled into the silicon wafer groove Inside, so that ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com