Strain capable of high yielding acid-resisting high-temperature alpha-amylase and application

A technology of acid resistance and amylase, applied in the field of bioengineering, can solve the problems of poor thermal stability and narrow pH range, and achieve the effect of stabilizing acid resistance and high temperature resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Mutagenesis and directional screening of embodiment 1 bacterial strain

[0041] The enzyme activity level of liquid fermentation of Bacillus licheniformis CGMCC NO.10785 needs to be further improved. In order to obtain a strain with high acid-resistant and high-temperature α-amylase, nitrosoguanidine mutagenesis was carried out until a strain with obvious growth changes was bred. The strain is fast and can be cultured in high density, and the enzyme activity level of acid-resistant and high-temperature α-amylase is further improved.

[0042] 1. Preparation of Bacterial Suspension

[0043] Take 300mL of Bacillus licheniformis CGMCC NO.10785 logarithmic phase seed liquid into six 50mL centrifuge tubes, centrifuge at 8000rpm for 5min, discard the supernatant, wash the precipitated bacteria twice with 600mL normal saline, and resuspend with 100-200mL normal saline It is the bacterial suspension.

[0044] 2. Nitrosoguanidine mutagenesis and coating screening plate

[0045...

Embodiment 2

[0053] Embodiment 2 liquid fermentation produces acid-resistant high-temperature α-amylase

[0054] Streak the seeds to isolate a single colony: Streak the frozen glycerol tube seeds of the Bacillus licheniformis mutant strain YBG-90036 on the seed slant medium to isolate a single colony, and culture at 37° C. for 30 h.

[0055] Seed slant medium formula: 4% corn starch, 3% yeast powder, 2% soybean peptone, 2% malt syrup, 0.4% calcium chloride, 1.5% ammonium chloride, 1.8% potassium dihydrogen phosphate, 1% agar powder, pH5.5.

[0056] Liquid seed culture: On the above-mentioned seed slant medium, pick a single colony with a high colony HC value (HC value = hydrolysis circle diameter / colony diameter), insert it into 200mL liquid seed medium (use a 500mL Erlenmeyer flask), 37°C , shaker speed 300 rpm / min, cultivate to OD 600nm The absorbance value is around 2.0.

[0057] Liquid seed medium: corn starch 4%, yeast powder 3%, soybean peptone 2%, malt syrup 2%, calcium chloride ...

Embodiment 3

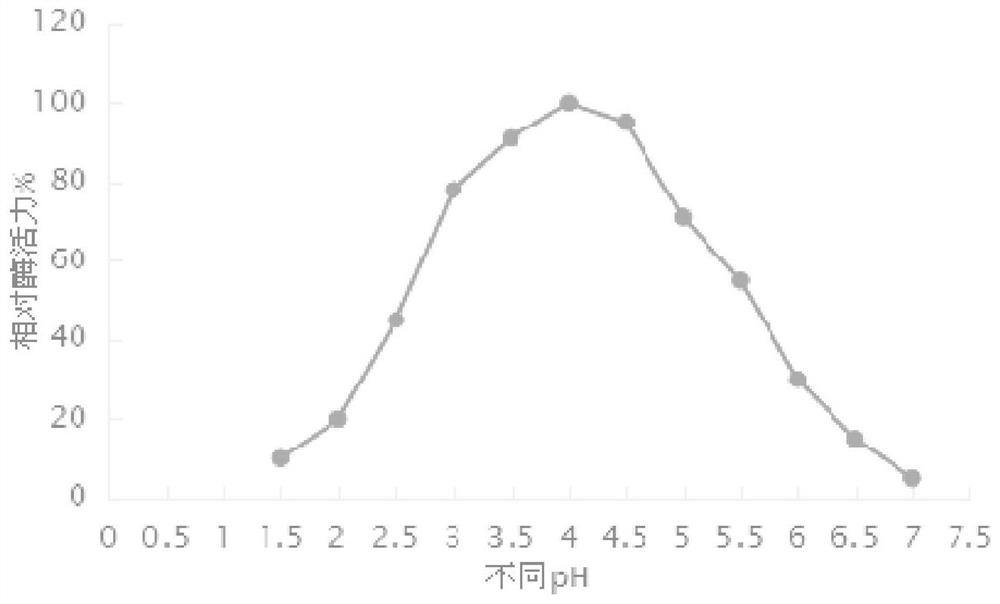

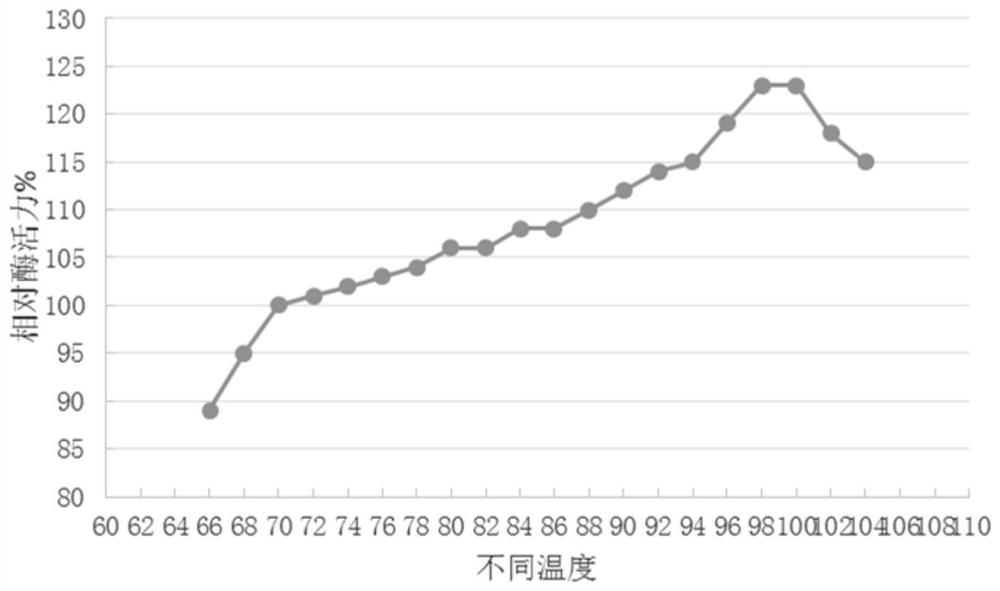

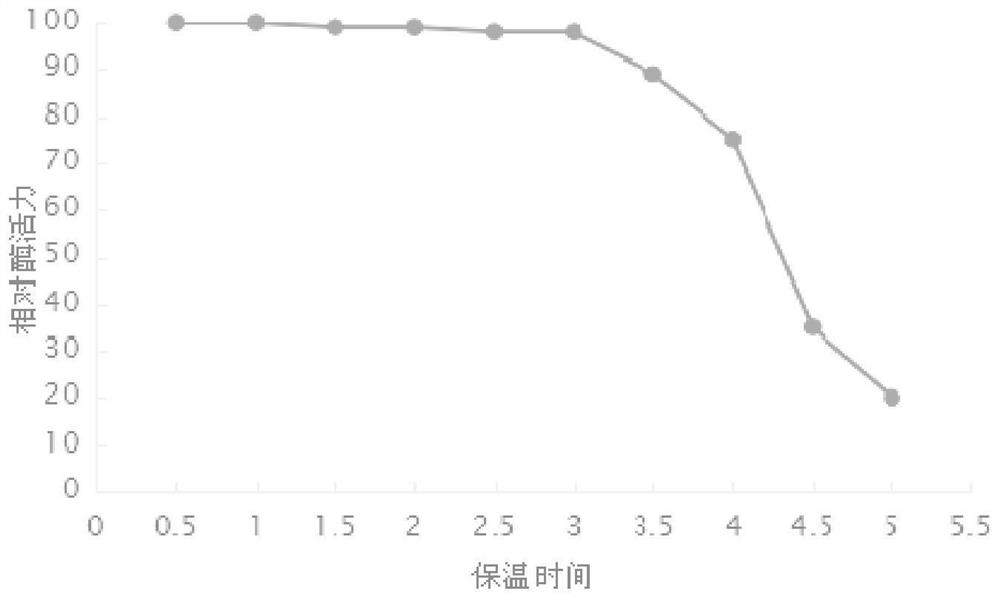

[0065] The basic properties of the acid-resistant high-temperature α-amylase produced by embodiment 3

[0066] Under the conditions of 70°C and pH 4.0, the enzyme activity was measured, and the acid-resistant high-temperature α-amylase sample with an enzyme activity of 92040U / mL was used as the benchmark, and the samples were taken for enzyme activity determination experiments at different temperatures and different pHs. . The optimum pH judgment standard is that the enzyme activity measured in different pH buffer solutions is more than 80% of the enzyme activity of the sample under the condition of 70°C, which is the optimum pH range of the enzyme. The criterion for the optimum temperature range is that under the condition of pH 4.0, the enzyme activity measured at different temperatures is more than 120% of the enzyme activity of the sample, which is the optimum temperature range of the enzyme. The acid-resistant high-temperature α-amylase produced by the mutant strain YBG-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com