Method for rapidly preparing organic fertilizer

An organic fertilizer and rapid technology, applied in the direction of organic fertilizer, inorganic fertilizer, fertilizer made of biological waste, etc., can solve the problems of public health impact, incomplete decomposition, crop hazards, etc., achieve good mold inhibition, good sterilization effect, The effect of high biosafety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Example 1 Rapid Manufacturing of Organic Fertilizers

[0035] 98 kg of biological waste and 2 kg of microwave absorbing material were put into a mixer and stirred evenly to form a mixture. In this embodiment, the biological waste can optionally be single or mixed types of chicken manure, duck manure, goose manure, pig manure, cow manure, sheep manure, horse manure and other fresh poultry manure or marsh slag, and the water content of the biological waste is about 50% to 90% (w / w). The microwave absorbing substance can optionally be single or multi-type mixed silicon carbide, rubber, coke, graphite, carbon powder, iron oxide, ferric oxide, zinc oxide, molybdenum sulfide, zirconium dioxide, barium titanate, Magnesium carbonate, and the particle size of the microwave absorbing substance is not greater than 1mm.

[0036] Put the biological waste into a tunnel microwave reactor. The tunnel microwave reactor comprises a tunnel microwave reaction chamber and a conveyor belt...

Embodiment 2

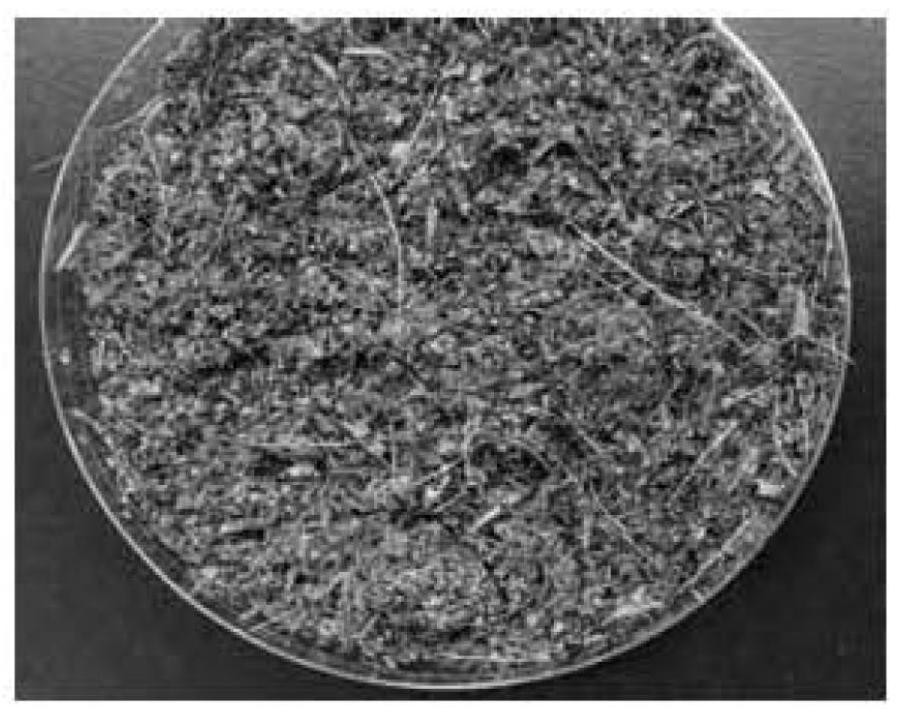

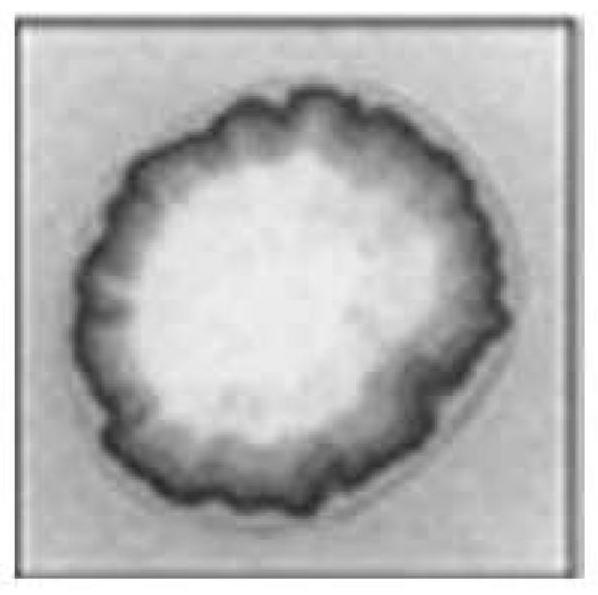

[0046] Example 2 Decomposition Judgment of Organic Fertilizer - Filter Paper Diffusion Graphics Determination Method

[0047] The organic fertilizer made in Example 1 (using chicken manure, pig manure, and biogas residue as raw materials respectively) was used as the experimental group samples, and untreated chicken manure, pig manure, and biogas residue were used as the control group samples. The steps of the filter paper diffusion imaging assay are as follows;

[0048] A. Put each sample into an oven, set the temperature at 60°C, and place it for 1 day after drying;

[0049] B. Take Sartorius 392 125mm filter paper, put it in a glass dish, then soak it with 0.5% (w / v) silver nitrate (AgNO3) solution in the fume hood, and place it in an oven to avoid light and air dry;

[0050] C, the fertilizer sample after step A is dried, weighs 10g and packs into a 250ml jar, and adds 1% NaOH of 100ml, shakes at room temperature for 5 hours and extracts;

[0051] D. Get 40ml of the fert...

Embodiment 3

[0055] Example 3 Decomposition Judgment of Organic Fertilizer-Solvita Decomposition Degree Detection Method

[0056] The organic fertilizer made in Example 1 (using chicken manure, pig manure, and biogas residue as raw materials respectively) was used as the experimental group samples, and untreated chicken manure, pig manure, and biogas residue were used as the control group samples. The steps of the Solvita maturity test method are as follows:

[0057] A. Adjust the humidity of each sample to 70%, and let it stand overnight;

[0058] B. Take 50g of the samples adjusted in step A, and put them into the test bottles respectively, so that the fertilizer is in the filling line, cover but not lock the upper cover, and let the air in the bottle balance for 1 hour;

[0059] C. Insert the carbon dioxide detection sheet and the ammonia detection sheet into the fertilizer sample in step B respectively, fasten the upper cover, and act for 4 hours;

[0060] D. Take out the test piece ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com