Method for modifying polyimide surface by laser texturing of circular pit array and injection of metal ions

A technology of metal ion implantation and polyimide, which is applied in the direction of ion implantation plating, laser welding equipment, metal processing equipment, etc., to achieve the effect of improving friction and wear performance, reducing friction coefficient, and increasing bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] (1) Ultrasonic cleaning of polyimide in polyionized water for 20 min, repeated 3 times, to remove surface pollutants;

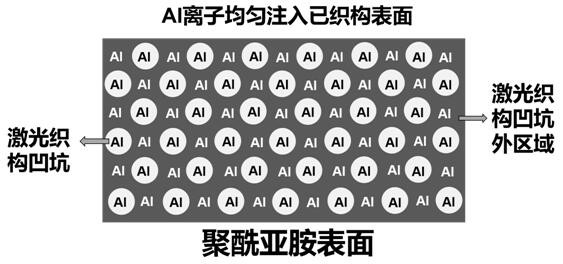

[0021] (2) Put the cleaned polyimide into the laser processing system, and use the "single pulse at the same point multiple times" process to texture the surface of the polyimide polymer with a circular pit array: adjust the scanning speed to 5 mm / s, power 10 W, pulse frequency fixed at 15 kHz, repeated marking times 35 times;

[0022] (3) Put the polyimide with textured surface into the vacuum chamber, and vacuum to 1×10 -4 Pa; the Al target is pre-installed in the vacuum chamber as the ion implantation material;

[0023] (4) Turn on the arc power supply, adjust the current to 20 A, the duty cycle to 56%, and generate a beam current density of 0.24 A / 100 cm 2 s, control the acceleration voltage -15 kV, use Mevva-V.Ru vacuum arc ion source to implant metal Al, the injection time is 250 s, take it out after the cavity is cooled, and obtain the modifie...

Embodiment 2

[0026] (1) Ultrasonic cleaning of polyimide in polyionized water for 20 min, repeated 3 times, to remove surface pollutants;

[0027] (2) Put the cleaned polyimide into the laser processing system, and use the "single pulse at the same point multiple times" process to texture the surface of the polyimide polymer with a circular pit array: adjust the scanning speed to 8 mm / s, power 6 W, pulse frequency fixed at 15 kHz, repeated marking times 50 times;

[0028] (3) Put the polyimide with textured surface into the vacuum chamber, and vacuum to 1×10 -4 Pa; the Al target is pre-installed in the vacuum chamber as the ion implantation material;

[0029] (4) Turn on the arc power supply, adjust the current to 17 A, the duty cycle to 56%, and generate a beam current density of 0.19 A / 100 cm 2 s, control the acceleration voltage -15 kV, use Mevva-V.Ru vacuum arc ion source to implant metal Al, the injection time is 160 s, take it out after the cavity is cooled, and obtain the modified...

Embodiment 3

[0032] (1) Ultrasonic cleaning of polyimide in polyionized water for 20 min, repeated 3 times, to remove surface pollutants;

[0033] (2) Put the cleaned polyimide into the laser processing system, and use the "single pulse at the same point multiple times" process to texture the surface of the polyimide polymer with a circular pit array: adjust the scanning speed to 2 mm / s, power 12 W, pulse frequency fixed at 15 kHz, repeated marking times 30 times;

[0034] (3) Put the polyimide with textured surface into the vacuum chamber, and vacuum to 1×10 -4 Pa; the Al target is pre-installed in the vacuum chamber as the ion implantation material;

[0035] (4) Turn on the arc power supply, adjust the current to 25 A, the duty cycle to 56%, and generate a beam current density of 0.28 A / 100 cm 2 s, control the acceleration voltage -15 kV, use Mevva-V.Ru vacuum arc ion source to implant metal Al, the injection time is 80 s, take it out after the cavity is cooled, and obtain the modified...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| friction coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com