Carbonyl iron powder composite wave-absorbing material and preparation method thereof

A technology of composite absorbing material and carbonyl iron powder, which is applied in the direction of carbonyl iron, silicon dioxide, antennas, etc., can solve the problems of magnetic permeability, magnetic loss mismatch, and low magnetic loss performance, and achieve good dispersion and reduce Agglomeration phenomenon, the effect of solving the low performance of magnetic loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0022] The present invention provides a kind of preparation method of carbonyl iron powder composite wave-absorbing material in the first aspect, described preparation method comprises the following steps:

[0023] (1) react carbonyl iron powder with hydrochloric acid solution, rinse with deionized water, then add deionized water and stir to obtain the first mixed solution;

[0024] (2) Dissolve tetraethyl orthosilicate (TEOS) and γ-glycidyl etheroxypropyl trimethoxysilane (KH-560) in ethanol and pour into the first mixed solution, mix well to obtain the second mixed solution;

[0025] (3) carrying out the hydrothermal reaction with the second mixed solution;

[0026] (4) Filter the reaction product obtained in step (3), and wash with ethanol and distilled water successively to obtain a solid product;

[0027] (5) drying the solid product to obtain SiO 2 Coated carbonyl iron powder.

[0028] According to some preferred embodiments, in step (1), the particle size of the carb...

Embodiment 1

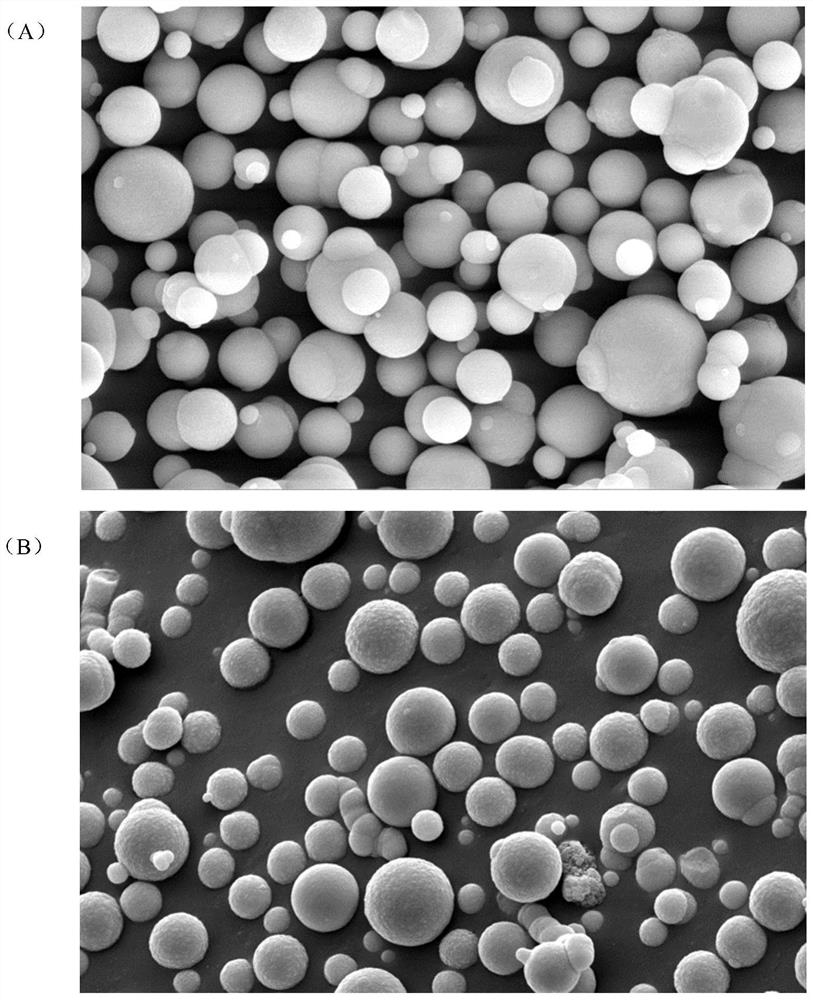

[0042] (1) First, carbonyl iron powder with an average particle size of 2 μm (see the SEM image for the figure 1 (A) 100g and 100mL of 0.02M hydrochloric acid solution were reacted under ultrasonic conditions for 5min, rinsed with deionized water for 3 times, then added deionized water, and stirred to make it turbid to obtain the first mixed solution;

[0043] (2) Dissolve 80mL of tetraethyl orthosilicate (TEOS) and 6mL of γ-glycidyl etheroxypropyl trimethoxysilane (KH-560) in ethanol, pour into the first mixed solution, and mix well to obtain the second mixed solution. liquid;

[0044] (3) Put the second mixed solution in a constant temperature water bath for 40°C hydrothermal reaction for 8 hours;

[0045] (4) the product obtained from the reaction of step (3) is filtered to obtain a solid, which is washed with ethanol and distilled water successively to obtain a solid product;

[0046] (5) Put the solid product in a vacuum drying oven at 50°C and dry it fully to obtain Si...

Embodiment 2

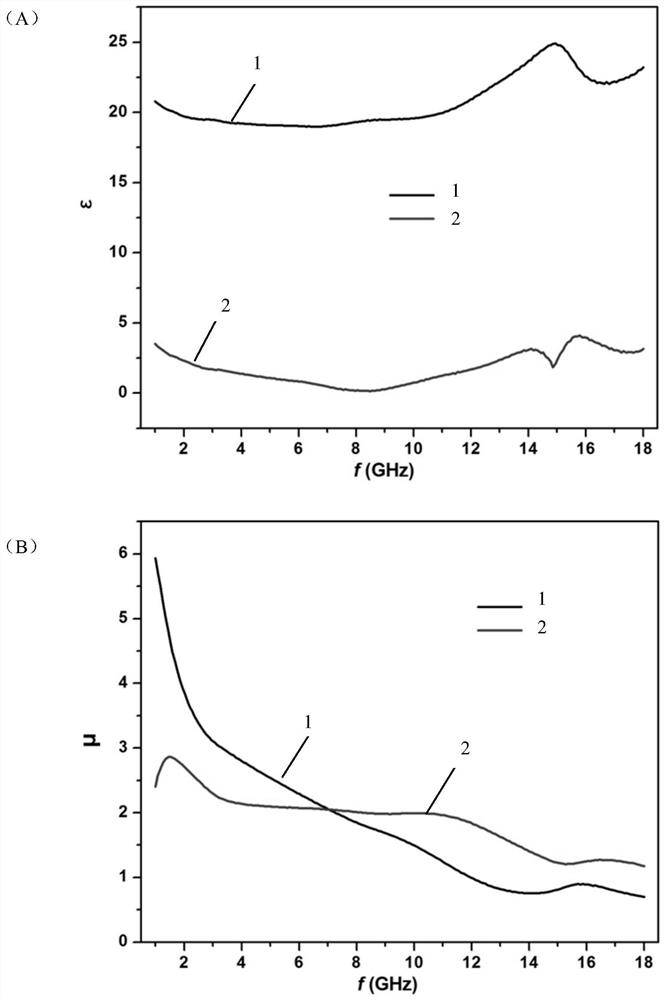

[0049] (1) First, react 100 g of carbonyl iron powder with an average particle size of 3 μm and 100 mL of 0.03 M hydrochloric acid solution under ultrasonic conditions for 5 minutes, rinse with deionized water for 3 times, then add deionized water, and stir to make it turbid to obtain the first mixture;

[0050] (2) Dissolve 100mL of tetraethyl orthosilicate (TEOS) and 8mL of γ-glycidyl etheroxypropyl trimethoxysilane (KH-560) in ethanol, pour into the first mixed solution, and mix well to obtain the second mixed solution. liquid;

[0051] (3) Put the second mixed solution in a constant temperature water bath for hydrothermal reaction at 50°C for 6 hours;

[0052] (4) the product obtained from the reaction of step (3) is filtered to obtain a solid, which is washed with ethanol and distilled water successively to obtain a solid product;

[0053] (5) Put the solid product in a vacuum drying oven at 50°C and dry it fully to obtain SiO 2 Coated carbonyl iron powder.

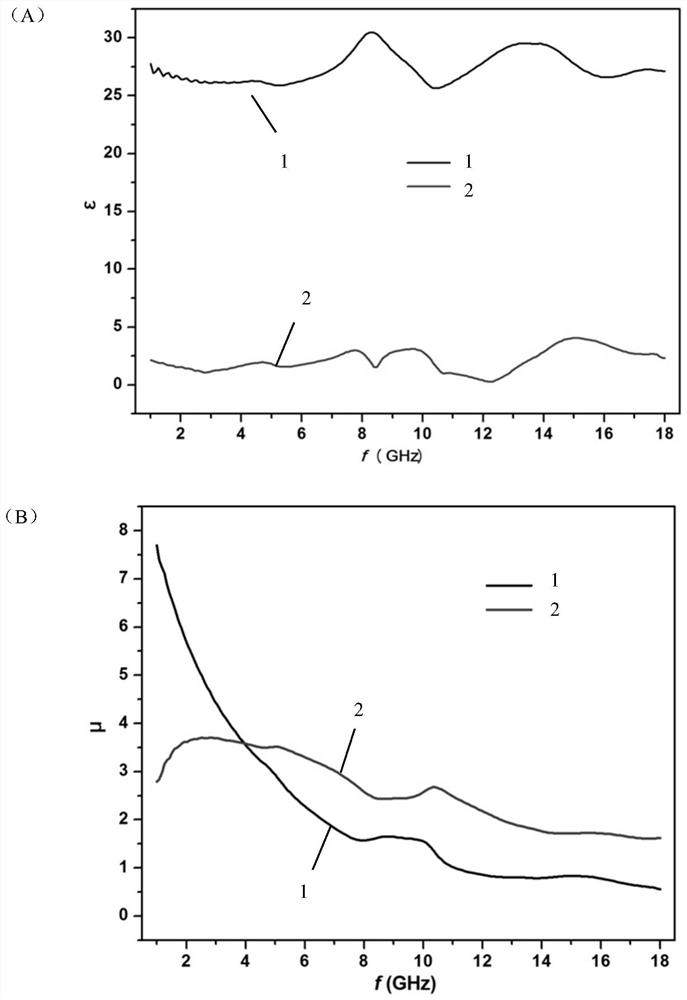

[0054] T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| volume | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com