A kind of preparation method of silver metal oxide flake electric contact

An electrical contact and oxide technology, applied in metal material coating process, contacts, circuits, etc., can solve the problems of easy occurrence of holes in the silver layer, limit of the minimum thickness of the silver layer, uneven speed, etc., to save welding Thickness of silver layer, saving precious metal resources, obvious effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0048] Further, when the AgMeO substrate is round or square, the preparation method includes the following steps:

[0049] ①AgMeO wire preparation: AgMeO wire is prepared by conventional internal oxidation process, pre-oxidation process or powder metallurgy process, and processed to the required specifications and state after drawing and annealing;

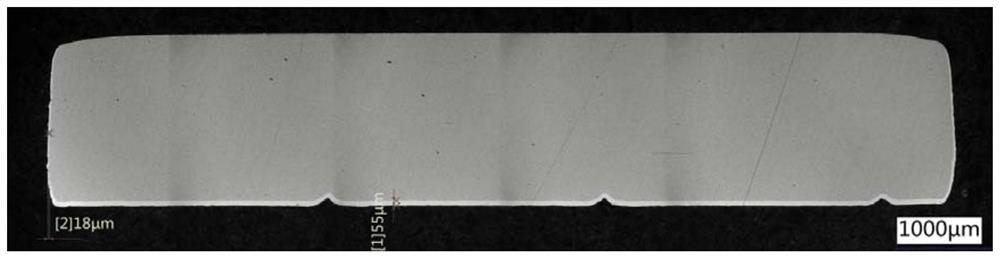

[0050] ②Cold heading forming: AgMeO wire is prepared by cold heading forming equipment to prepare AgMeO sheet blanks, and the welding surface of AgMeO sheet blanks has logo patterns during cold heading forming;

[0051] ③Surface treatment: AgMeO flakes are cleaned and degreased by ultrasonic cleaning equipment to obtain AgMeO flakes with a clean surface and no organic residues;

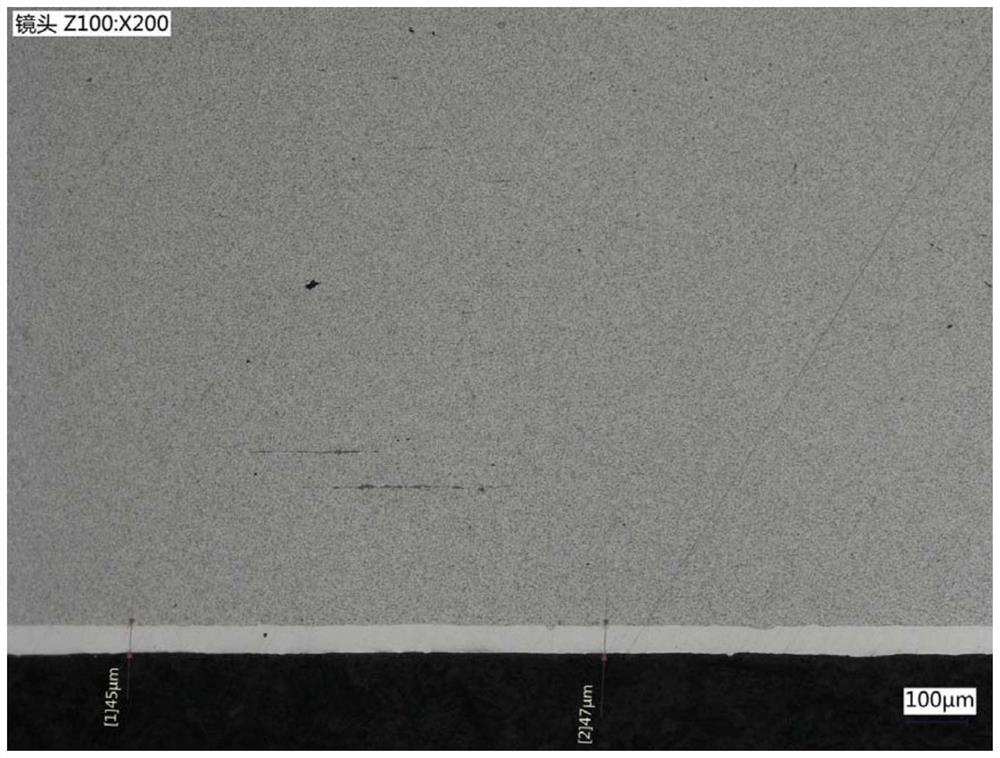

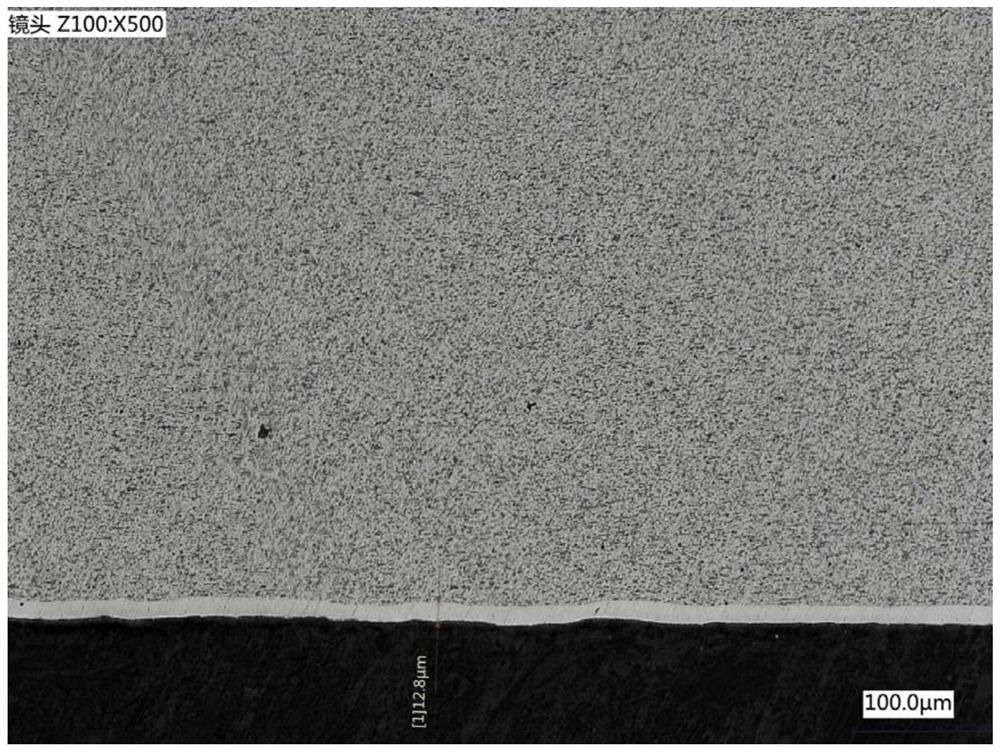

[0052] ④Magnetron sputtering silver plating: Arrange the AgMeO flakes with the pattern facing up in the tray, place the tray in the magnetron sputtering equipment, install the pure silver target, close the coating chamber and pre-evacuate to ≤5× 10 -4 P...

Embodiment 1

[0073] Embodiment 1: The AgMeO substrate is silver tin oxide indium oxide:

[0074] a) Melt 22kg of silver, 2kg of tin and 1kg of indium in the graphite crucible of an intermediate frequency melting furnace to form a silver-tin-indium alloy melt, which is prepared into silver-tin-indium alloy powder by high-pressure water atomization equipment; the silver-tin-indium alloy powder is baked Drying, sieving, and powder oxidation to prepare silver tin oxide indium oxide powder with a silver content of 85%;

[0075] b) Silver tin oxide indium oxide powder is pressed into a φ105mm ingot by cold isostatic pressing equipment. After sintering at 850°C for 4 hours, it is extruded into a strip with a size of 50×4mm, rolled to a size of 50×2.25mm, and the surface treatment is removed. Impurities and oil stains on the surface are obtained to obtain semi-finished strips of silver tin oxide and indium oxide;

[0076] c) Silver tin oxide and indium oxide semi-finished strips are closely packe...

Embodiment 2

[0081] Embodiment two: the AgMeO substrate is silver tin oxide:

[0082] a) Mix 19.5kg of silver powder, 2.73kg of tin oxide powder and 0.5kg of additive powder in a plow-shovel mixer for 4 hours, wherein the silver powder is -200 mesh, the average particle size of tin oxide powder is 5 μm, and the average particle size of additive powder is 2 μm. Prepared as silver tin oxide powder with a silver content of 88%;

[0083] b) Silver tin oxide powder is pressed into a φ88mm ingot by cold isostatic pressing equipment. After sintering at 900°C for 6 hours, it is extruded into a 40×4mm strip, rolled to a 40×2.45mm size, and the surface is treated to remove the surface Impurities and oil stains are removed to obtain silver tin oxide semi-finished strips;

[0084] c) Silver tin oxide semi-finished strips are closely packed on the barrel of the magnetron sputtering equipment, put the barrel into the magnetron sputtering silver plating equipment, install the pure silver target, close t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com