A kind of max@m composite electrical contact reinforcement phase material, composite electrical contact material and preparation method

A technology of electrical contact material and enhanced phase, applied in the direction of contacts, circuits, electrical switches, etc., can solve the problems of poor Ag/Ni anti-welding performance, reduced workability of melting and welding tendency, and large material transfer, etc. The effect of good, low technical cost and convenient process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

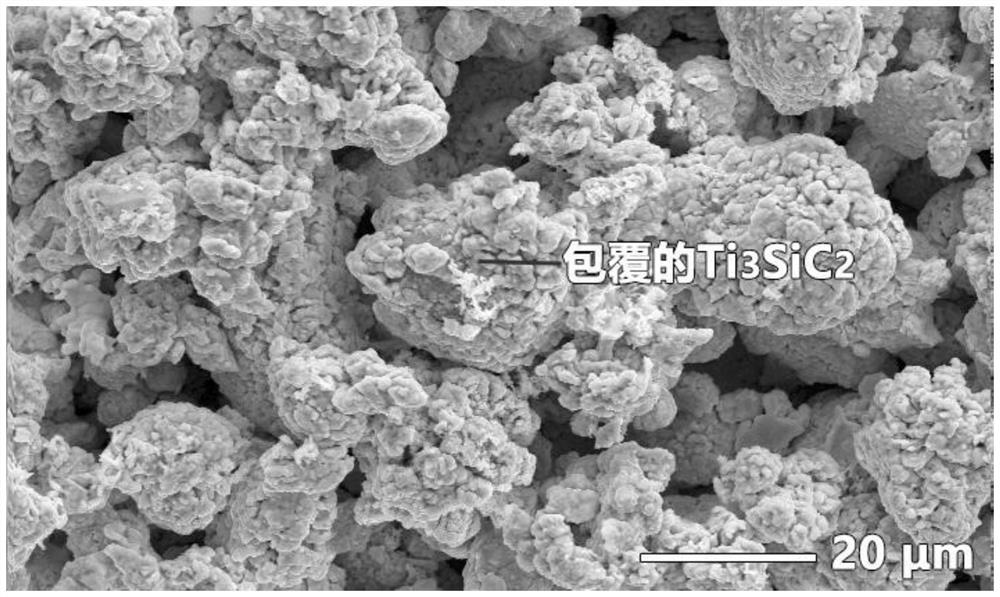

[0033] The preparation method of the composite electrical contact reinforced phase material specifically generates MXene in situ on the surface of the sensitized parent MAX phase material in an acidic environment, generates active MXene sites after activation treatment, and then uses electroless plating to coat the surface of the material. metal nanoparticles;

[0034] By sensitizing the parent MAX material, MXene material is generated in situ on its surface, and after activation, electroless plating is used to form surface-coated metal nanoparticles MAX@M. The process is simple and can be carried out at room temperature. After covering the MAX@M surface, the material properties are greatly improved.

[0035] Specifically, the preparation method of the composite electrical contact reinforcing phase material includes the following steps:

[0036] S1: Weigh the MAX powder and add the acid solution, and place them together in a cylindrical reaction kettle, and activate them by m...

Embodiment 1

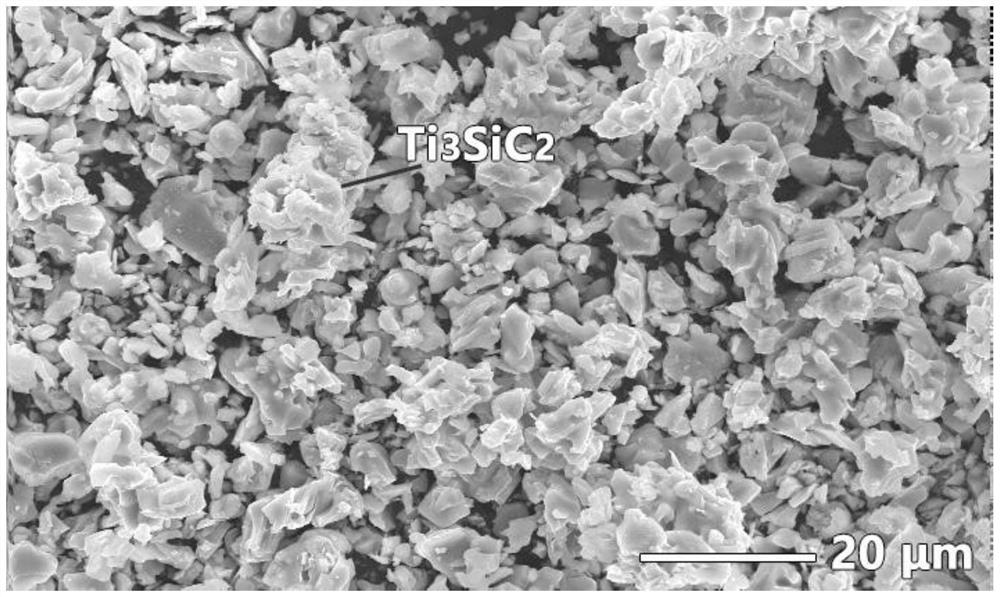

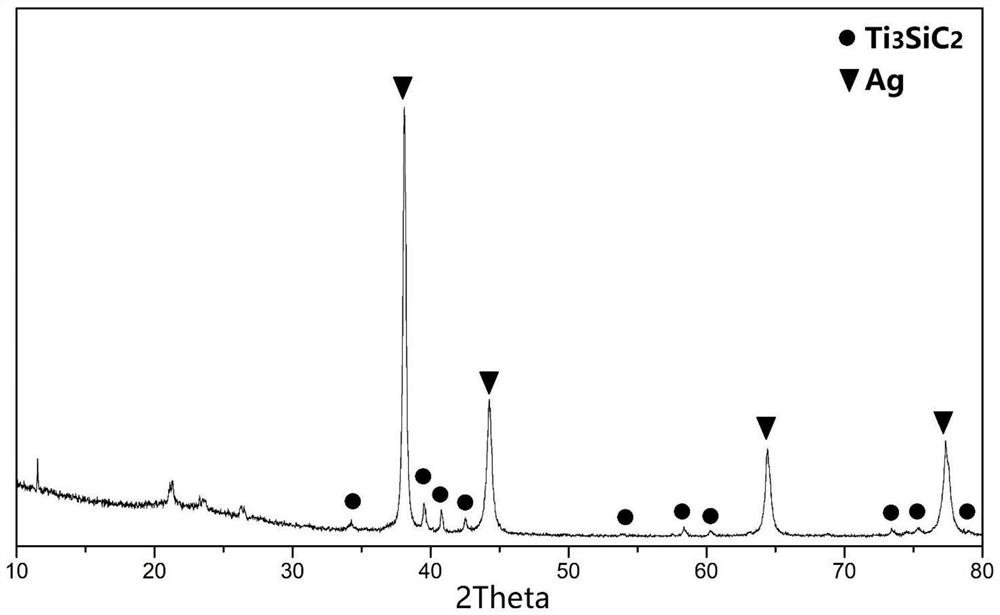

[0051] According to the mass ratio of liquid:solid=10:1, 10gTi was 3 SiC 2 The powder was added to HF acid solution with a concentration of 10 wt%, and stirred at a temperature of 30 rpm in a magnetic stirrer for 1 hour at a speed of 30 rpm; a 10 mL centrifuge tube was used to multiply the mixed solution, and the centrifuge was set at 600 rpm. The material was centrifuged for 1 hour, and the mixture was centrifuged and then freeze-dried for 1 hour using a freeze dryer to remove moisture to obtain Ti on the surface. 3 C 2 Ti at the site 3 SiC 2 powder; the mixed powder was immersed in 10 wt% PdCl 2 1 hour in the activator, after filtration, add AgNO with a concentration of 20wt% 3 , CH 3 OH, HCHO, NaOH, EDTA-2Na, C 4 H 4 O 6 KNa·4H 2 O, K 4 [Fe(CN 6 )] 3H 2 The mixture was stirred at 50 rpm for 1 hour, and the nanocomposite powder was washed with deionized water until the deionized water after cleaning was transparent. The nanocomposite powder was taken out and dri...

Embodiment 2

[0054] According to the mass ratio of liquid:solid=20:1, 20gTi was 3 SiC 2 The powder was added to HF acid solution with a concentration of 20 wt%, and stirred at a temperature of 50 rpm for 4 hours in a magnetic stirrer at a temperature of 40 °C; a 10 mL centrifuge tube was used to multiply the mixed solution, and the centrifuge was set at 1500 rpm. The material was centrifuged for 2 hours, the mixture was centrifuged and then freeze-dried by a freeze dryer for 2 hours to remove moisture to obtain Ti on the surface. 3 C 2 Ti at the site 3 SiC 2 powder; this mixed powder was immersed in PdCl at a concentration of 20 wt% 2 1.5 hours in the activator, after filtration, put in CuSO with a concentration of 30wt% 4 ·5H 2 O, CH 3 OH, HCHO, NaOH, EDTA-2Na, C 4 H 4 O 6 KNa·4H 2 O, K 4 [Fe(CN 6 )] 3H 2The mixture was stirred at 100 rpm for 2 hours, and the nanocomposite powder was washed with deionized water until the deionized water after cleaning was transparent. The na...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com