Microbiological detection device and microbiological detection method

A microbial detection and microbial technology, applied in the field of microbial detection, can solve the problems of low sensitivity, complex operation and time-consuming, etc., and achieve the effect of improving applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

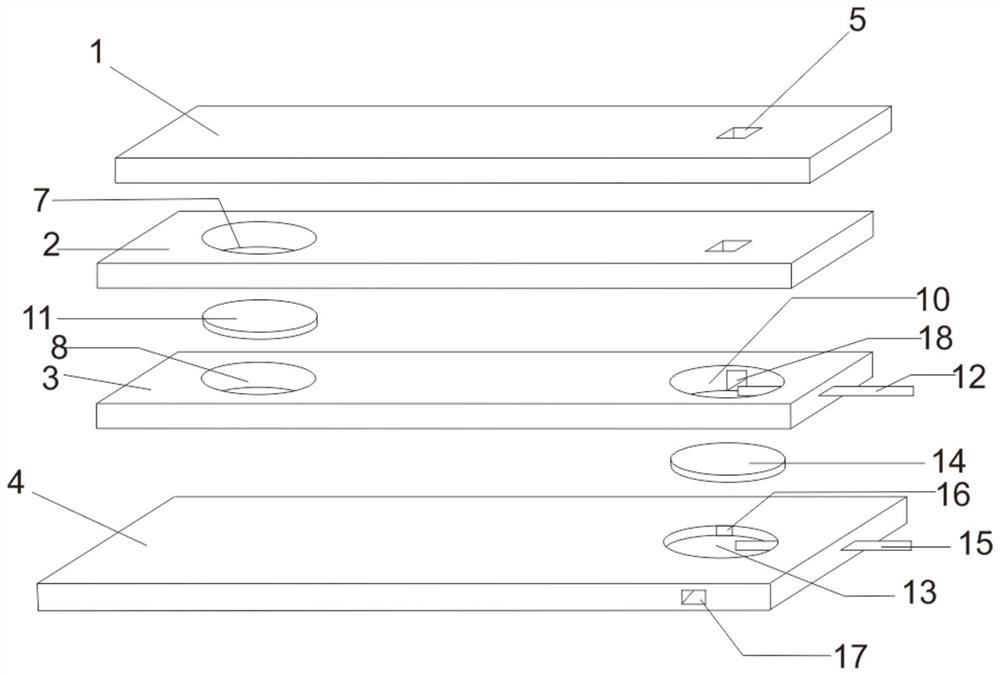

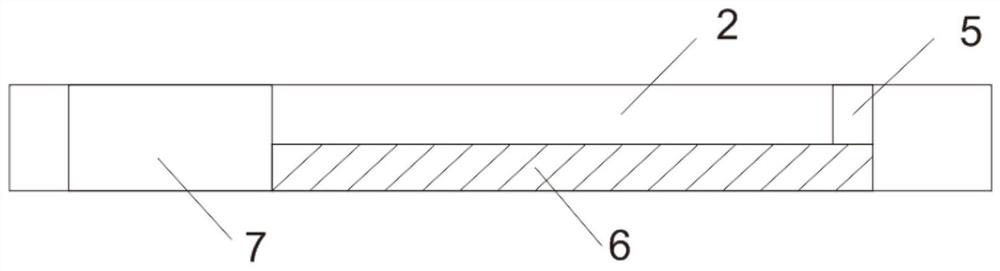

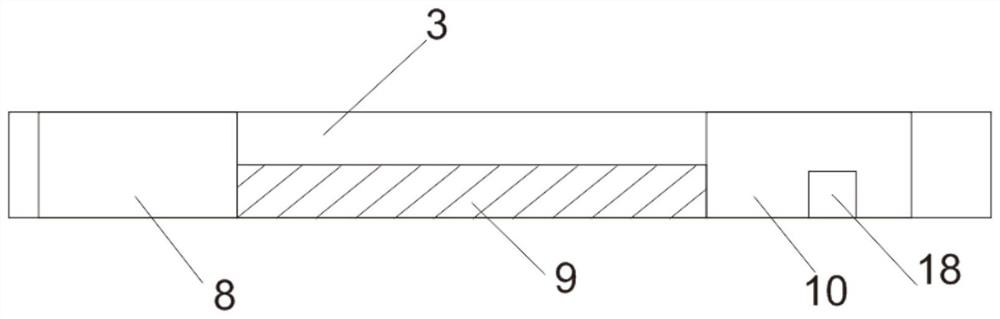

Image

Examples

Embodiment 1

[0047] The sensitive element is made of small-porous membrane and macroporous membrane, the small-porous membrane is mesoporous silicon membrane, and the macroporous membrane is anodized aluminum oxide membrane (AAO);

[0048] The preparation method of small-porous mesoporous silicon membrane is as follows: it is prepared by solution growth method, and the specific preparation method is: select 2cm×2cm ITO glass as the growth substrate of mesoporous silicon membrane, and first use 1mol / L NaOH ethanol solution, acetone solution, ethanol solution and deionized water were ultrasonically washed for 15 minutes in sequence, and then the cleaned ITO glass was immersed in 70mL water, 30mL ethanol, 10μL ammonia water, 0.16g hexadecyl trimethyl bromide Ammonium and 80 μL tetraethyl silicate mixed solution, and reacted at 60 ° C for 20 h; after the reaction was completed, dry the ITO glass at 100 ° C overnight; then, the grown mesoporous silicon film Place the HCl ethanol solution of 0.1...

Embodiment 2

[0051] The sensitive element is made of a small-porous membrane of mesoporous silicon membrane and a macroporous membrane of porous silicon nitride membrane (p-SiN);

[0052] The preparation process of the mesoporous silicon membrane of the small pore membrane: it is prepared by the solution growth method. The specific preparation method is: select 2cm×2cm ITO glass as the growth substrate of the mesoporous silicon membrane, and firstly use 1mol / L NaOH to ITO glass Ethanol solution, acetone solution, ethanol solution and deionized water were ultrasonically washed for 15 minutes in sequence, and then the cleaned ITO glass × glass was immersed in 70mL water, 30mL ethanol, 10μL ammonia water, 0.16g cetyltrimethylammonium bromide and 80 μL of tetraethyl silicate, and reacted at 60 ° C for 14 h; after the reaction was completed, the ITO glass was dried at 100 ° C overnight; then, the grown mesoporous silicon film was mixed with ITO The glass is placed in 0.1mol / L HCl ethanol soluti...

Embodiment 3

[0055] The sensitive element is made of mesoporous carbon membrane of small-pore membrane and anodized aluminum membrane of macroporous membrane;

[0056] The preparation method of the mesoporous carbon membrane: the mesoporous carbon membrane is mainly synthesized on a silicon wafer, using phenolic resin as the carbon precursor, and the triblock polymer F127 as the template agent, and is prepared by the solution volatilization self-assembly method. The specific preparation process of the mesoporous carbon membrane is as follows: (1) Place the silicon wafer (20mm×20mm) in 90°C piranhaic acid (the volume ratio of concentrated sulfuric acid and 30% hydrogen peroxide is 2:1) and wash it for 30 minutes (2) take NaOH as catalyst, phenol and formaldehyde as raw material (mass ratio 1:6:10) to synthesize water-soluble phenolic resin solution, and use absolute ethanol as solvent to prepare mass Fraction is 20% phenolic resin solution; (3) spin coating a drop of phenolic resin solution...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com