Zinc-copper bimetallic MOF electrode material and preparation method thereof

An electrode material and bimetallic technology, applied in the field of zinc-copper bimetallic MOF electrode materials and its preparation, can solve the problems of high difficulty in electrolyte matching, low electronic conductivity, structural decomposition and collapse, etc., and achieve good electrochemical performance and high Effects of cycle stability and performance improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

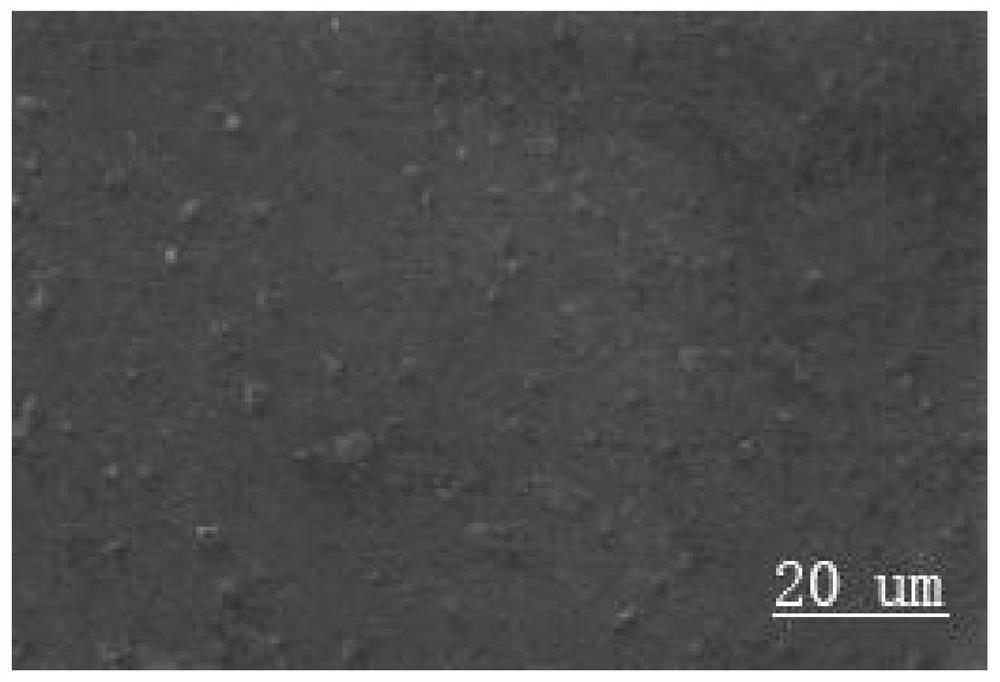

[0021] A Zn-Cu bimetallic MOF electrode material

[0022] Zn-Cu bimetallic MOFs were prepared by the following methods:

[0023] Step 1: 8.2g 2-methylimidazole was dissolved in 25mL methanol to obtain 2-methylimidazole methanol solution; 5.0g Zn(OH) 2 Dissolve in 15mL ammonia water to get Zn(OH) 2 Ammonia solution; 8.0 g of copper sulfate is prepared into a solution of 0.2 mol / L, and then ammonia is slowly added dropwise to the copper sulfate solution until forming a copper ammonia solution;

[0024] Step 2: Zn(OH) 2 Ammonia solution and copper ammonia solution were slowly added to 2-methylimidazole methanol solution, stirred at room temperature for 48 hours, centrifuged, and H 2 O / CH 3 The OH mixed solution was washed three times and dried overnight at 80°C to obtain the Zn-Cu bimetallic MOF.

[0025] Preparation of zinc-copper bimetallic MOF electrode materials:

[0026] Add 5g of zinc-copper bimetallic MOF and 5g of multi-walled carbon nanotubes (MWCNTs) into the reac...

Embodiment 2

[0028] A Zn-Cu bimetallic MOF electrode material

[0029] Zn-Cu bimetallic MOFs were prepared by the following methods:

[0030] Step 1: 8.2g 2-methylimidazole was dissolved in 30mL methanol to obtain 2-methylimidazole methanol solution; 5.0gZn(OH) 2 Dissolve in 18mL ammonia water to get Zn(OH) 2 Ammonia solution; 8.0 g of copper sulfate is prepared into a solution of 0.2 mol / L, and then ammonia is slowly added dropwise to the copper sulfate solution until forming a copper ammonia solution;

[0031] Step 2: Zn(OH) 2 Ammonia solution and copper ammonia solution were slowly added to 2-methylimidazole methanol solution, stirred at room temperature for 48 hours, centrifuged, and H 2 O / CH 3 The OH mixed solution was washed three times and dried overnight at 80°C to obtain the Zn-Cu bimetallic MOF.

[0032] Preparation of zinc-copper bimetallic MOF electrode materials:

[0033] Add 5g of zinc-copper bimetallic MOF and 5g of multi-walled carbon nanotubes (MWCNTs) into the react...

Embodiment 3

[0035] A Zn-Cu bimetallic MOF electrode material

[0036] Zn-Cu bimetallic MOFs were prepared by the following methods:

[0037] Step 1: 8.2g 2-methylimidazole was dissolved in 35mL methanol to obtain 2-methylimidazole methanol solution; 5.0gZn(OH) 2 Dissolve in 20mL ammonia water to get Zn(OH) 2 Ammonia solution; 8.0 g of copper sulfate is prepared into a solution of 0.2 mol / L, and then ammonia is slowly added dropwise to the copper sulfate solution until forming a copper ammonia solution;

[0038] Step 2: Zn(OH) 2 Ammonia solution and copper ammonia solution were slowly added to 2-methylimidazole methanol solution, stirred at room temperature for 48 hours, centrifuged, and H 2 O / CH 3 The OH mixed solution was washed three times and dried overnight at 80°C to obtain the Zn-Cu bimetallic MOF.

[0039] Preparation of zinc-copper bimetallic MOF electrode materials:

[0040] Add 5g zinc-copper bimetallic MOF and 5g multi-walled carbon nanotubes (MWCNTs) into the reactor, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com