A kind of ce-mof electrode material and its preparation method and application

An electrode material and reaction technology, applied in the field of Ce-MOF electrode material and its preparation, can solve the problems of low active material load on the electrode, reduce the conductivity of the electrode, and restrict the electrochemical performance, so as to achieve good electrochemical performance and improve performance, the effect of excellent Coulombic efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

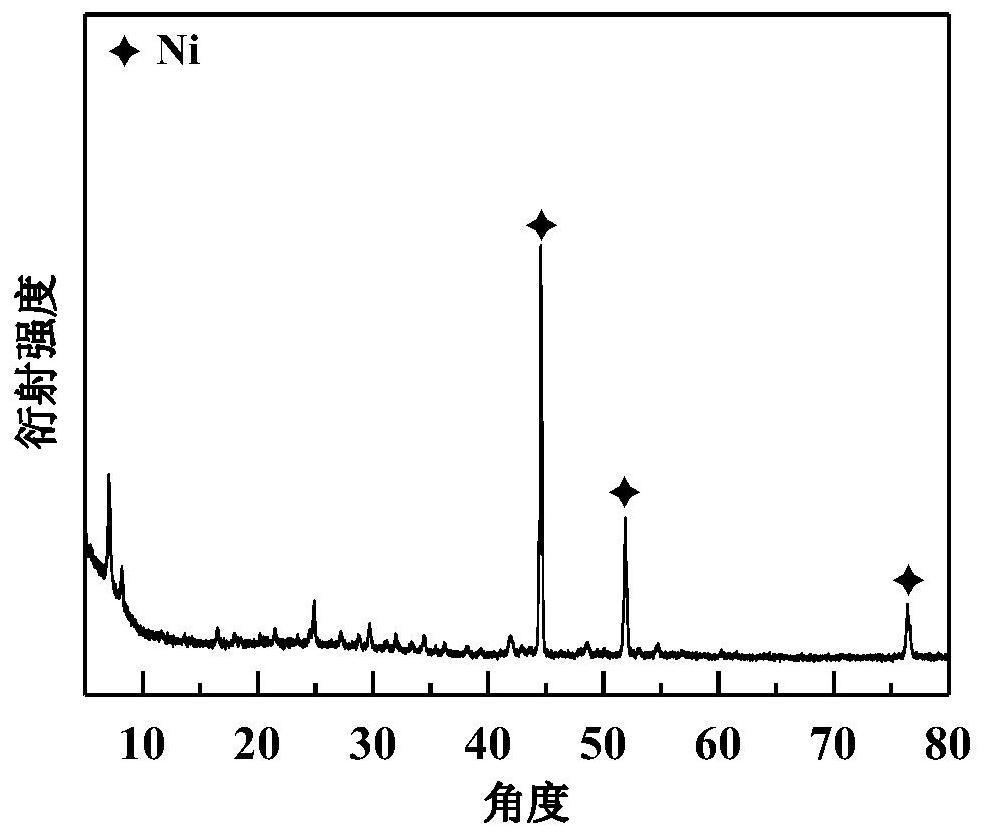

[0021] (1) Foam nickel (surface density is 350g / m 2 , thickness 0.5mm) was cut into a rectangle of 1cm×5.5cm, put into a beaker, added acetone, and ultrasonically cleaned for 20min in an ultrasonic cleaner (500W) to remove surface oil stains to obtain foamed nickel-1.

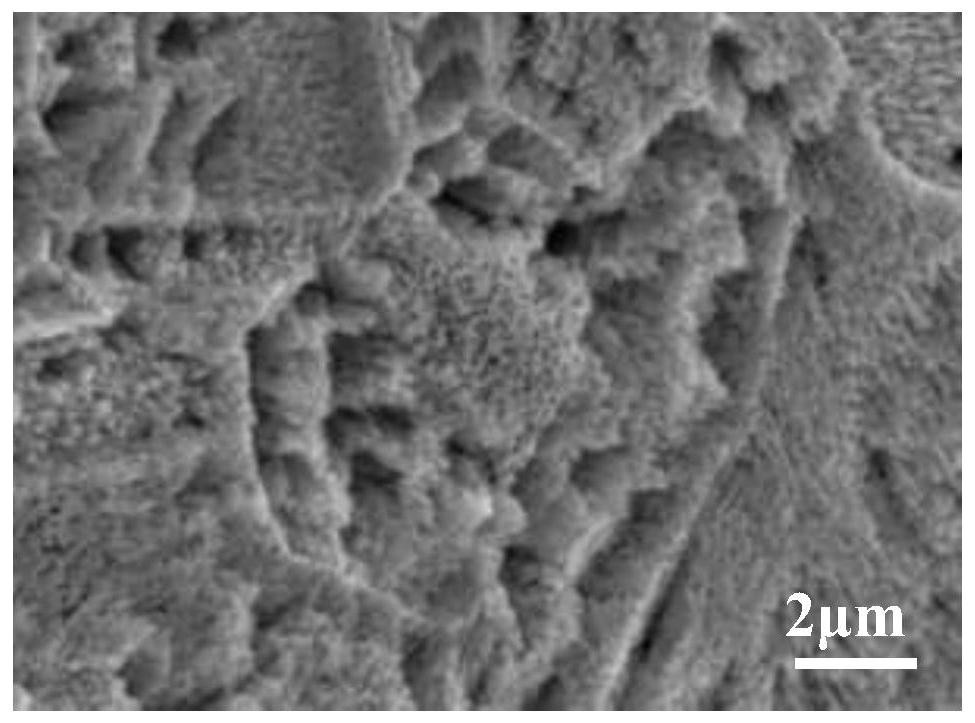

[0022] (2) Take a 250ml PTFE beaker and configure 100ml of a mixed aqueous solution of 1.2g terephthalic acid and 1.2g ammonium fluoride as the electrolyte. The beaker was used as an electrolytic cell, and two nickel-1 foams were used as a working electrode and a counter electrode respectively, and the depth of both electrodes immersed in the solution was 1 cm. Using the constant potential method, set the electrode potential to 2V, and the time is 10min. During this process, keep the temperature of the electrolyte at 120°C, and feed N20min in advance. 2 , until the end of the experiment, the working electrode was removed to obtain foamed nickel-2.

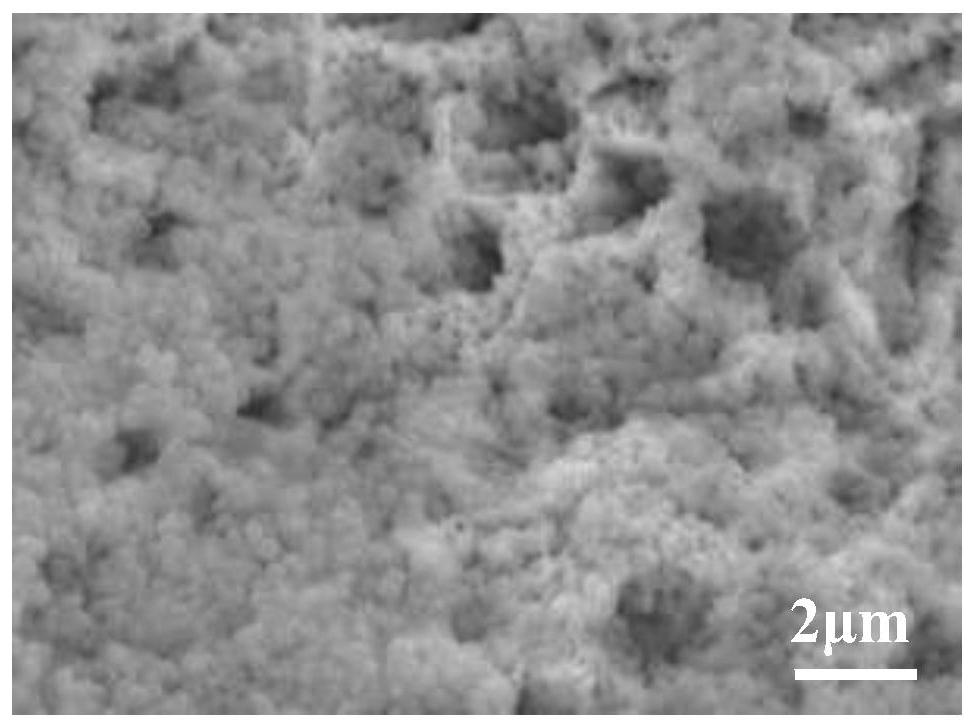

[0023] (3) At room temperature, use 10ml of water and 10ml o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com