Method for stripping ferroelectric single crystal thin film

A ferroelectric single crystal and thin film technology, applied in circuits, electrical components, electrical solid devices, etc., can solve the problems of uneven stress distribution, time-consuming, crystal fragmentation, etc., to reduce the injection energy and dose, reduce Cost-effective, easy-to-peel effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

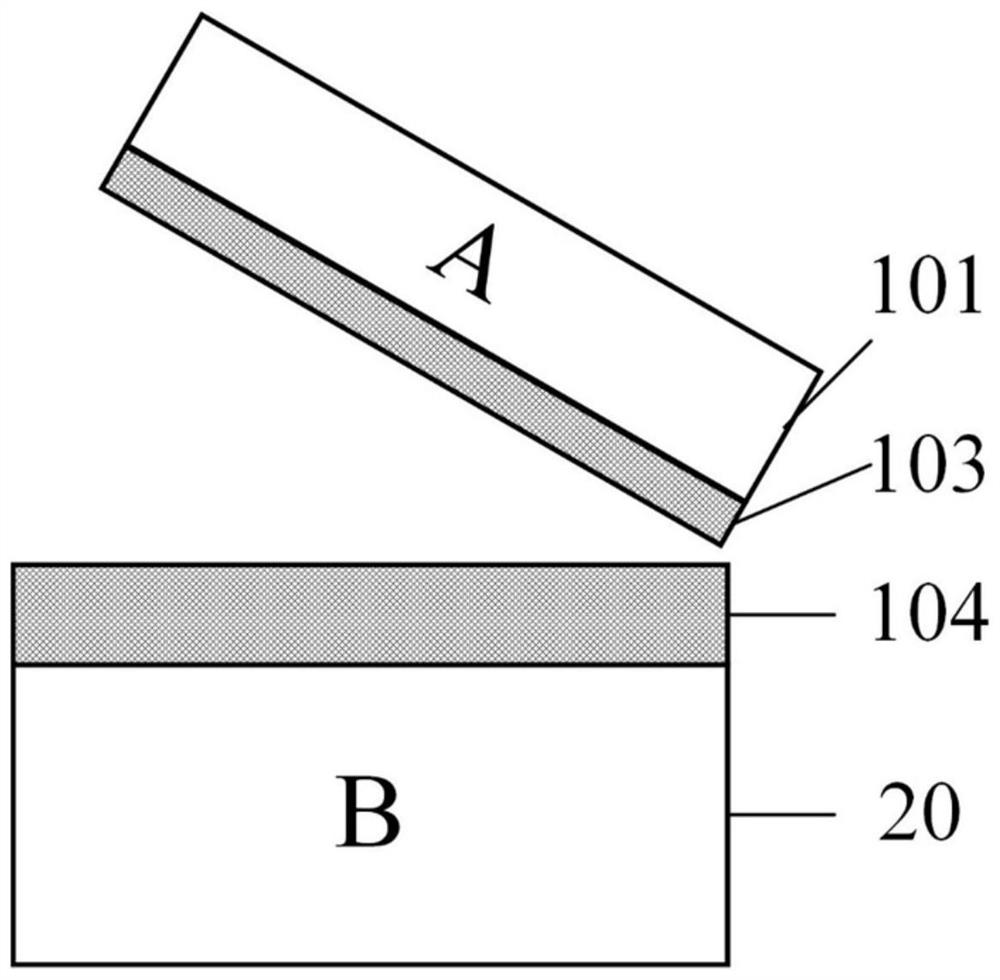

[0038] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments. This embodiment is carried out on the premise of the technical solution of the present invention, and detailed implementation and specific operation process are given, but the protection scope of the present invention is not limited to the following embodiments.

[0039] In the drawings, for the sake of clarity, the thicknesses of layers and regions are exaggerated, and the dimensional proportional relationship among the various parts in the illustration does not reflect the actual dimensional proportional relationship.

[0040] This embodiment provides a method for peeling off a ferroelectric single crystal thin film. First, use a proton exchange method to form a Li-ion-poor second-phase single crystal layer with a controllable thickness on the surface of a ferroelectric single crystal material; then, use an ion implantation method Stripping o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com