A kind of preparation method and product of copper alloy composite material for electronic packaging

A technology for electronic packaging and composite materials, which is applied in the field of preparation of copper alloy composite materials for electronic packaging, can solve the problem that the comprehensive performance cannot meet the high requirements of electronic packaging, and achieves the effect of improving electromagnetic shielding performance, simple installation and good thermal conductivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

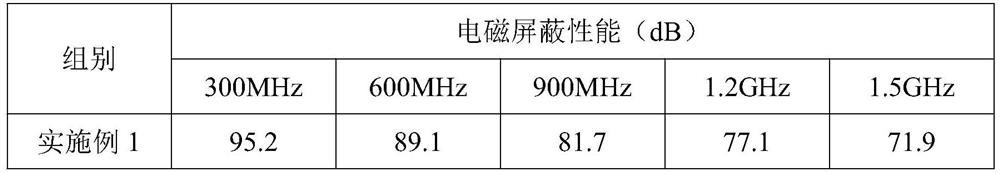

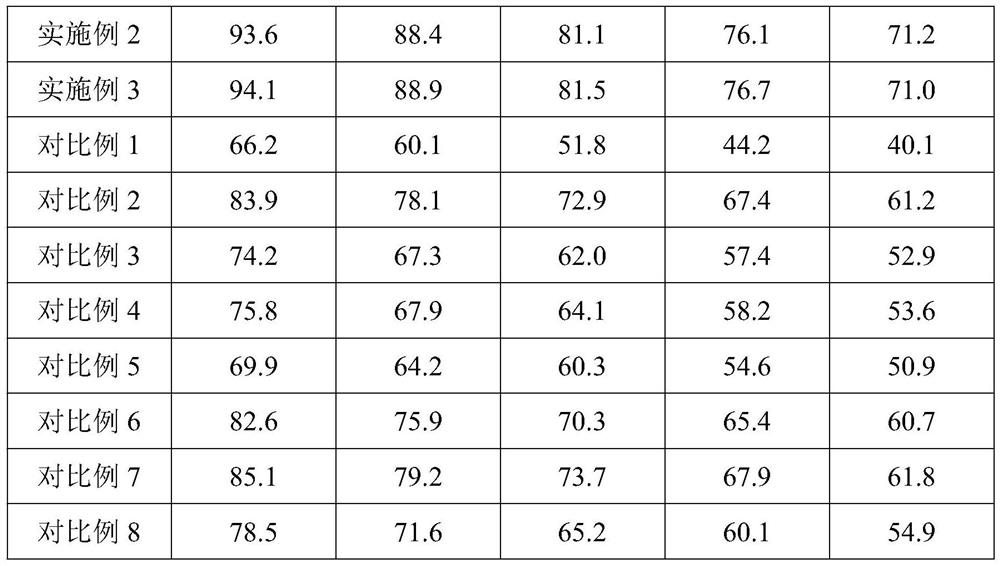

Examples

Embodiment 1

[0036] The preparation of copper alloy composite material for electronic packaging includes the following steps:

[0037] (1) Preparation of electroless silver plating solution: add ammonia water with a mass fraction of 25% to a silver nitrate solution with a concentration of 10 g / L until the solution is clarified to obtain the main salt solution of electroless silver plating; add glucose into deionized water to obtain a concentration It is a reducing solution of 100g / L;

[0038] (2) Preparation of electroplating solution: add nickel sulfate hexahydrate solution, nickel dichloride hexahydrate solution, ascorbic acid solution, iron salt solution, sodium saccharin solution, sodium lauryl sulfate solution and CNTs water dispersion to the boric acid solution in turn solution to obtain electroplating solution, wherein the concentration of boric acid is 15g / L, the concentration of nickel sulfate hexahydrate is 100g / L, the concentration of nickel dichloride hexahydrate solution is 10...

Embodiment 2

[0043] Preparation of copper alloy composite materials for electronic packaging:

[0044] (1) Preparation of electroless silver plating solution: add ammonia water with a mass fraction of 20% to a silver nitrate solution with a concentration of 8g / L until the solution is clarified to obtain the main salt solution of electroless silver plating; add glucose into deionized water to obtain the concentration It is a reducing solution of 110g / L;

[0045] (2) Preparation of electroplating solution: add nickel sulfate hexahydrate solution, nickel dichloride hexahydrate solution, ascorbic acid solution, iron salt solution, sodium saccharin solution, sodium lauryl sulfate solution and CNTs water dispersion to the boric acid solution in turn liquid, obtains electroplating solution, wherein the concentration of boric acid is 25g / L, the concentration of nickel sulfate hexahydrate is 130g / L, the concentration of nickel dichloride hexahydrate solution is 15g / L, the concentration of ascorbic ...

Embodiment 3

[0050] The preparation of copper alloy composite material for electronic packaging includes the following steps:

[0051] (1) Preparation of electroless silver plating solution: add ammonia water with a mass fraction of 30% to a silver nitrate solution with a concentration of 12 g / L until the solution is clarified to obtain the main salt solution of electroless silver plating; add glucose into deionized water to obtain the concentration It is a reducing solution of 90g / L;

[0052] (2) Preparation of electroplating solution: add nickel sulfate hexahydrate solution, nickel dichloride hexahydrate solution, ascorbic acid solution, iron salt solution, sodium saccharin solution, sodium lauryl sulfate solution and CNTs water dispersion to the boric acid solution in turn liquid, obtain electroplating solution, wherein the concentration of boric acid is 20g / L, the concentration of nickel sulfate hexahydrate is 115g / L, the concentration of nickel dichloride hexahydrate solution is 12g / L...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com