Preparation method of denitrification carbon source for sewage treatment

A technology for sewage treatment and denitrification, applied in water/sewage treatment, adsorbed water/sewage treatment, water/sludge/sewage treatment, etc. Good denitrification utilization, abundant sources, and the effect of promoting activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

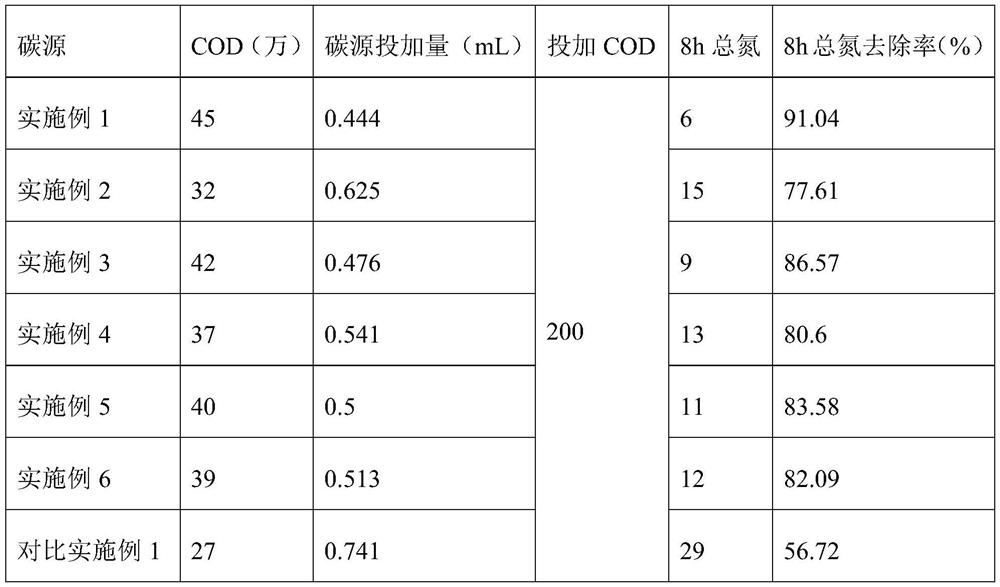

Examples

Embodiment 1

[0024] 60g poly (L-glutamic acid) (molecular viscosity is 40000) and 50g potassium hydroxide are dissolved in 300mL glycerol, and then 10g starch is immersed in this solution for reaction, the reaction temperature is 110 ℃, and the reaction time is 15h, a mixed solution was obtained after the reaction, and then 20g of polyvinyl alcohol and 8g of glycerol monostearate were added to the obtained mixed solution, stirred evenly and reacted at 70°C for 2h, cooled to room temperature and added with 15g of agar, trace elements (Mg 2+ , Fe 3+ , Zn 2+ , Cu 2+ , K + mix) 0.03g and vitamin B 1 0.02g, stir evenly, and dry to obtain denitrification carbon source.

Embodiment 2

[0026] 40g poly(L-aspartic acid) (molecular viscosity is 30000) and 50g sodium carbonate are dissolved in 200mL glycerol, then 10g starch is immersed in the solution for reaction, the reaction temperature is 120°C, and the reaction time is 10h, a mixed solution was obtained after the reaction, and then 10 g of polyvinyl alcohol and 5 g of glycerol monostearate were added to the obtained mixed solution, stirred evenly, and reacted at 80 ° C for 1 h, cooled to room temperature, and added with 15 g of gelatin and trace elements. (Mg 2+ , Fe 3+ , Zn 2+ , Cu 2+ , K + mix) 0.03g and vitamin B 12 0.02g, then stir evenly and dry to obtain denitrification carbon source.

Embodiment 3

[0028] Dissolve 80g of poly(L-aspartic acid) (molecular viscosity of 30000) and 100g of sodium carbonate in 400mL of glycerol, then immerse 10g of starch in the solution for reaction, the reaction temperature is 100°C, and the reaction time is 20h, after the reaction is completed, a mixed solution is obtained, then 20g of polyvinyl alcohol and 5g of sodium stearoyl lactylate are added to the obtained mixed solution, stirred evenly and reacted at 60°C for 2h, cooled to room temperature and added with 15g of gelatin, trace elements (Mg 2+ , Fe 3+ , Zn 2+ , Cu 2+ , K + mix) 0.03g and vitamin B 1 and B 12 0.02g, then stir evenly and dry to obtain denitrification carbon source.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com