High-layer-thickness low-temperature sintering method and equipment for selective laser sintering

A laser sintering and low temperature sintering technology, applied in the field of additive manufacturing, can solve the problems of limited 3D molding speed, large laser energy loss, low sintering efficiency, etc., to achieve excellent electrical conductivity, high reusability, and increased sintering speed. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

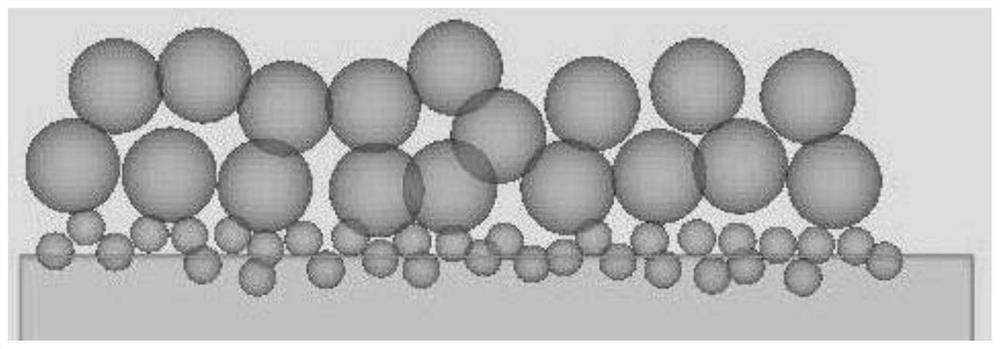

Method used

Image

Examples

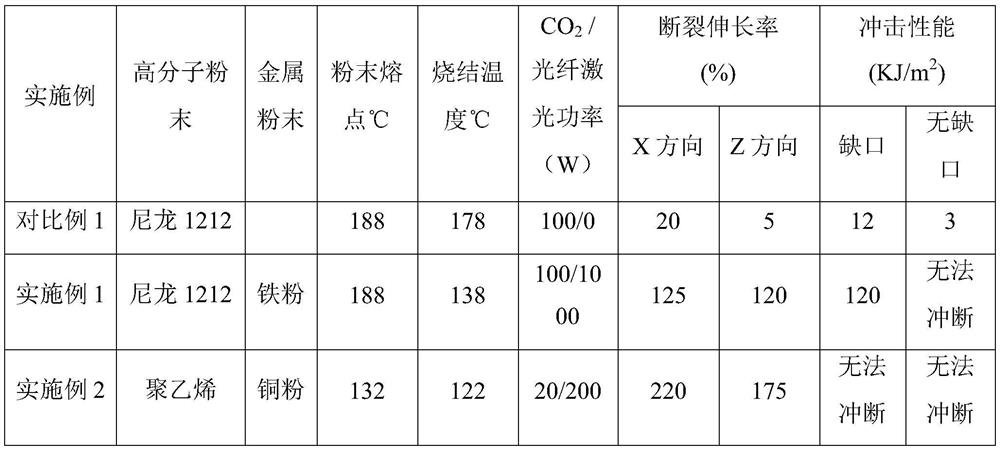

Embodiment 1

[0033](1) First, lay iron powder with a thickness of 0.02mm on the piston of the working cylinder, and then lay nylon 1212 with a thickness of 1.0mm on the iron powder, and preheat the above two layers of powder to a set temperature of 138°C. The set temperature is 50℃ lower than the melting point of nylon 1212;

[0034](2) Use CO with a wavelength of 10600nm and a rated power of 100W2The laser sinters the above two layers of powder with a sintering power of 100W and a sintered line spacing of 0.3mm, so that nylon 1212 powder is melted, and then sintered with a 1000W fiber laser with a wavelength of 1000nm rated power, and its sintering power is 1000W, sintered line spacing is 0.3mm;

[0035](3) Repeat steps 1 and 2 until the sintering of the workpiece is completed, and the sintering of the workpiece is completed.

Embodiment 2

[0037](1) First, lay copper powder with a thickness of 0.01mm on the piston of the working cylinder, and then lay polyethylene powder with a thickness of 0.3mm on the copper powder, and preheat the above two layers of powder to the set temperature of 122°C , The set temperature is 10°C lower than the melting point of the polyethylene powder;

[0038](2) Use CO with a wavelength of 10600nm and a rated power of 30W2The laser sinters the above-mentioned two layers of powder with a sintering power of 20W and a sintered line spacing of 0.08mm, so that the polyethylene powder is melted, and then sintered with a 200W fiber laser with a wavelength of 2000nm and a rated power. The sintering power is 200W, sintered line spacing is 0.08mm;

[0039](3) Repeat steps 1 and 2 until the sintering of the workpiece is completed, and the sintering of the workpiece is completed.

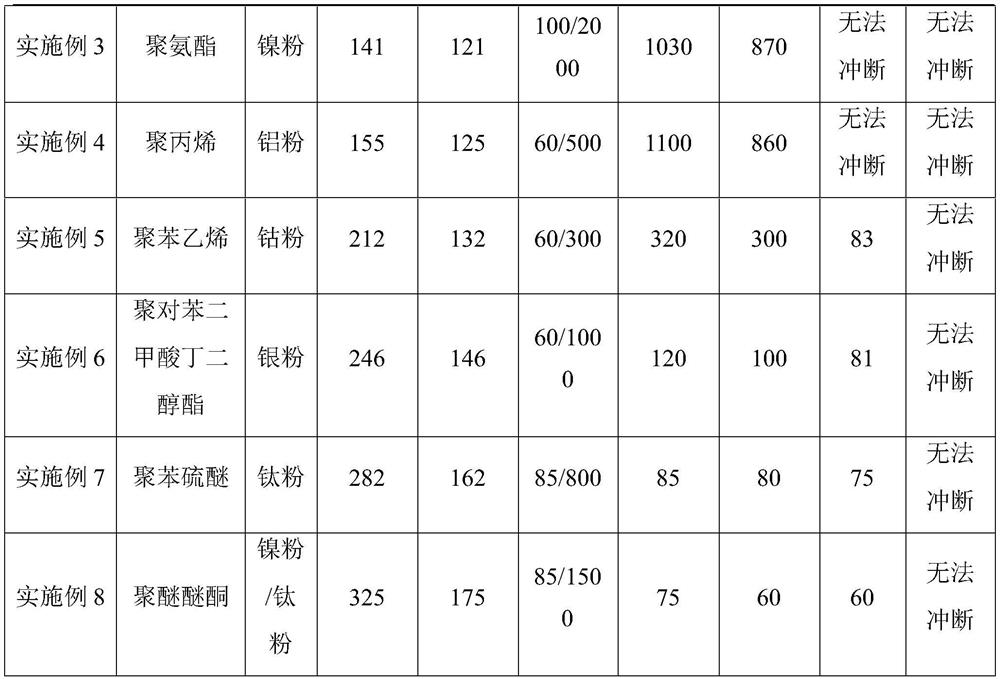

Embodiment 3

[0041](1) First, lay a layer of nickel powder with a thickness of 0.02mm on the piston of the working cylinder, and then pave a layer of polyurethane powder with a thickness of 0.5mm on the nickel powder, and preheat the above two layers of powder to a set temperature of 121°C. The set temperature is 20°C lower than the melting point of the polyurethane powder;

[0042](2) Use CO with a wavelength of 10600nm and a rated power of 100W2The laser sinters the above two layers of powder with a sintering power of 100W and a sintered line spacing of 0.5mm, so that the polyethylene powder is melted, and then sintered with a 2000W fiber laser with a wavelength of 405nm and a rated power. The sintering power is 2000W, the sintered line spacing is 0.5mm;

[0043](3) Repeat steps 1 and 2 until the sintering of the workpiece is completed, and the sintering of the workpiece is completed.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com