Growth process of magnesium silicate crystal with doped quadrivalent chromium

A tetravalent chromium magnesium silicate and growth method technology, which is applied in crystal growth, single crystal growth, single crystal growth, etc., can solve the problems of reduced iridium volatilization loss, large iridium crucible loss, and uneven concentration. Oxygen-containing time, meeting market demand, and reducing the effect of oxidation and volatilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

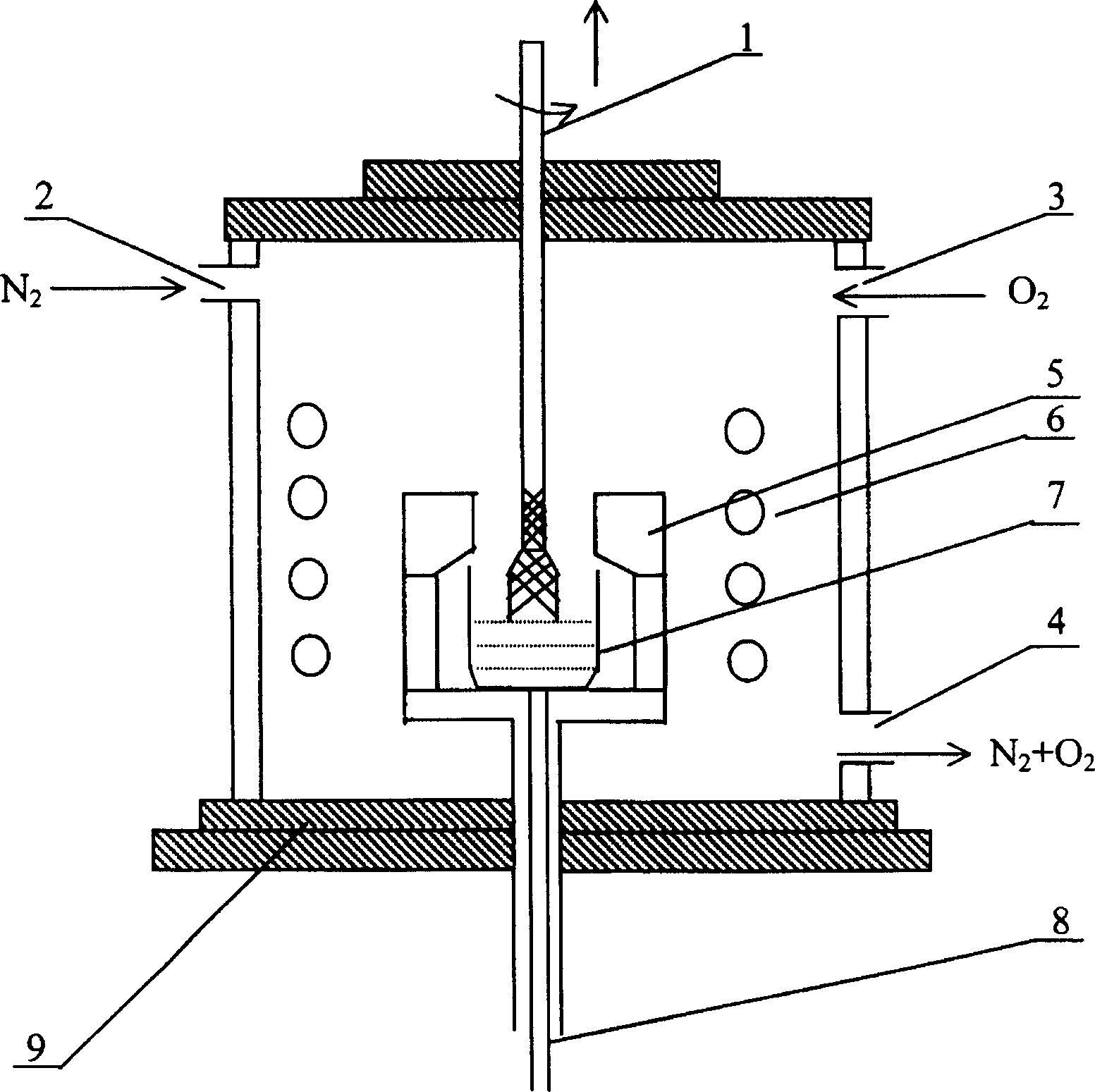

[0015] Cr 4+ : Mg 2 SiO 4 crystal growth. The selected intermediate frequency induction heating pulling furnace is as figure 1 shown.

[0016] On the outer surface of the iridium crucible 7, according to the weight percentage of 80% zirconia powder and 20% iridium powder, a protective layer is sprayed with plasma spraying technology, and the thickness of the protective layer is 0.5mm. mm, capacity 650 grams. 55.80% MgO and 42.72% SiO are proportioned by weight 2 and 1.48% Cr 2 o 3 The briquetting powder is packed into the iridium crucible 7, and the iridium crucible 7 is packed into figure 1 In the lifting furnace, after the body of furnace 9 is evacuated, the vacuum degree reaches 10 -6 Pa, stop vacuuming, fill with nitrogen, and heat until the raw materials are completely melted, N 2 In a flowing state, the flow rate is maintained at 200ml / min, and the air pressure is maintained at +0.25kg / cm 2 . Keep the growth temperature at 1890°C for 1 hour, plant the seeds, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com