Control device and method for converter smelting through CO2 and argon of rotary kiln

A converter smelting and control device technology, applied in the field of metallurgy and steel, can solve the problems of difficult to recover and discharge carbon dioxide, difficult to utilize waste heat, pollute environmental energy and other problems, and achieve the effects of easy control of decomposition temperature, reduction of production cost and high temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The technical solutions of the present invention are described below through specific embodiments. On the premise that there is no conflict with the purpose of the present invention, the embodiments mentioned below and the technical features in the embodiments can be combined with each other.

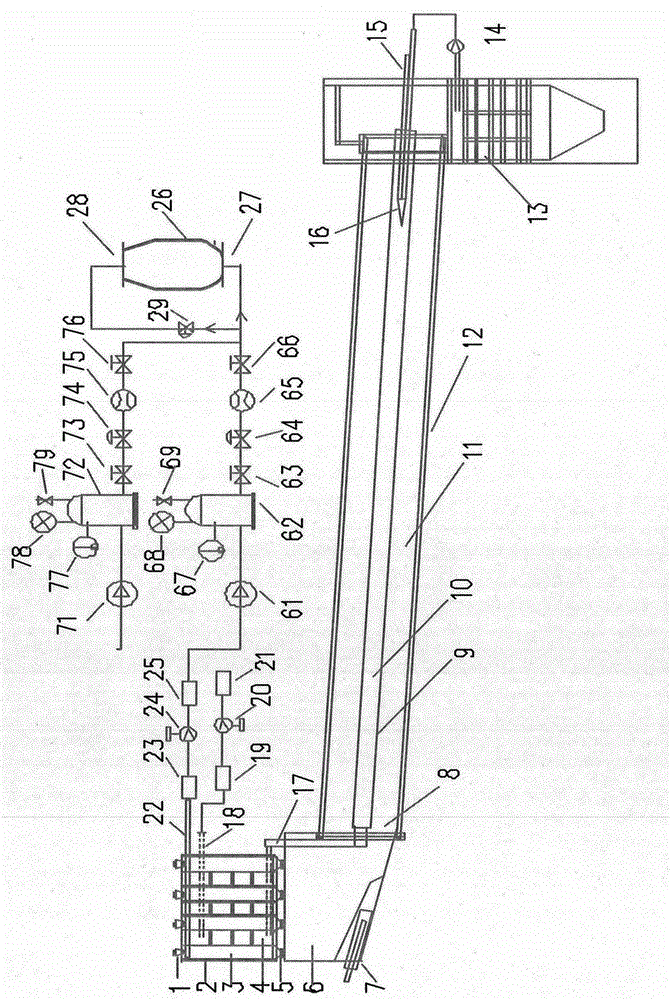

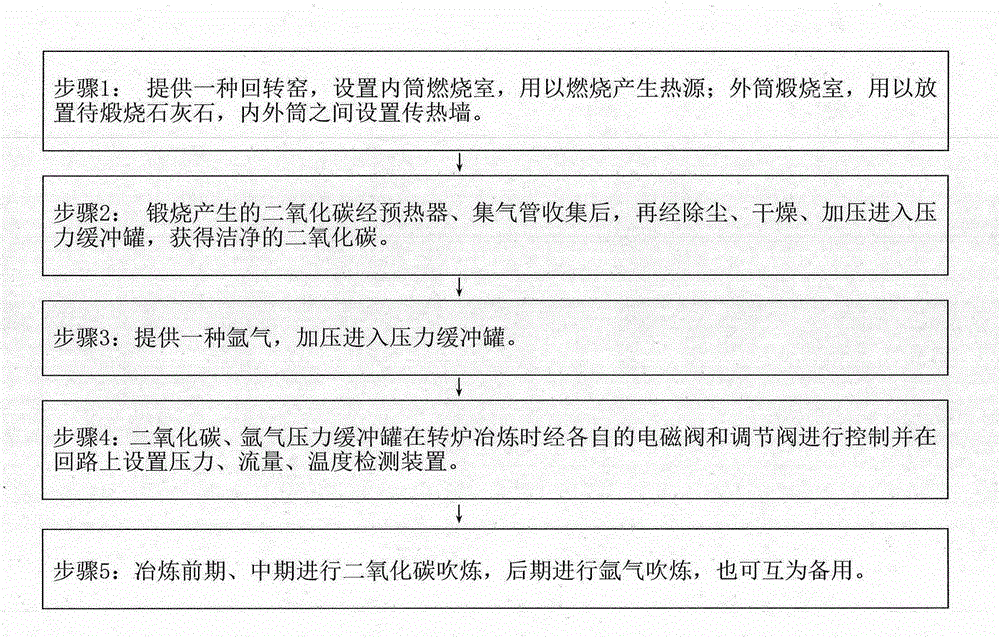

[0039] Such as figure 1 As shown, the technical solution adopted in the present invention is: the rotary kiln part includes a rotary kiln inner cylinder combustion chamber for combustion to generate heat; an outer cylinder calciner chamber for placing limestone to be calcined, and a heat transfer wall is arranged between the inner and outer cylinders. The carbon dioxide produced after calcining limestone is preheated by the preheater to the limestone, collected by the gas collecting pipe, and then dedusted, dried and pressurized into the pressure buffer tank to obtain clean carbon dioxide gas; the converter smelting part includes carbon dioxide gas, argon The compound smelting co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com