Self-lubricating bearing based on fiber fabric modification and manufacturing method thereof

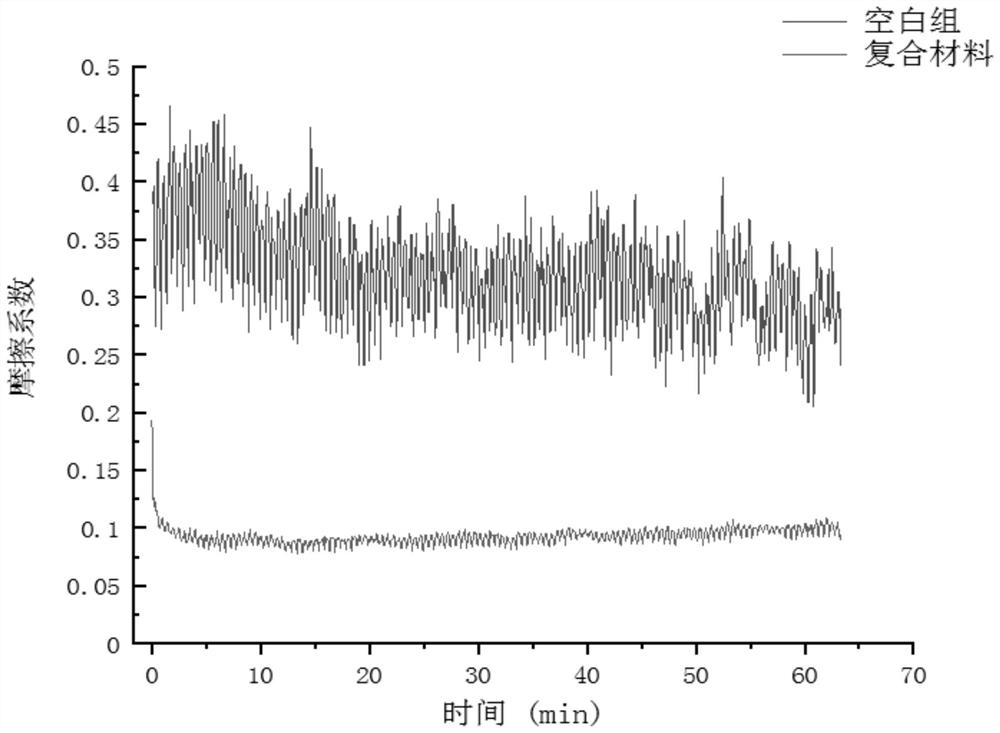

A self-lubricating bearing and fiber fabric technology, applied in the direction of bearing, fiber type, fiber treatment, etc., can solve the problem of unsatisfactory tribological performance, and achieve the effect of good self-lubricating performance, small wear amount and wide application range.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

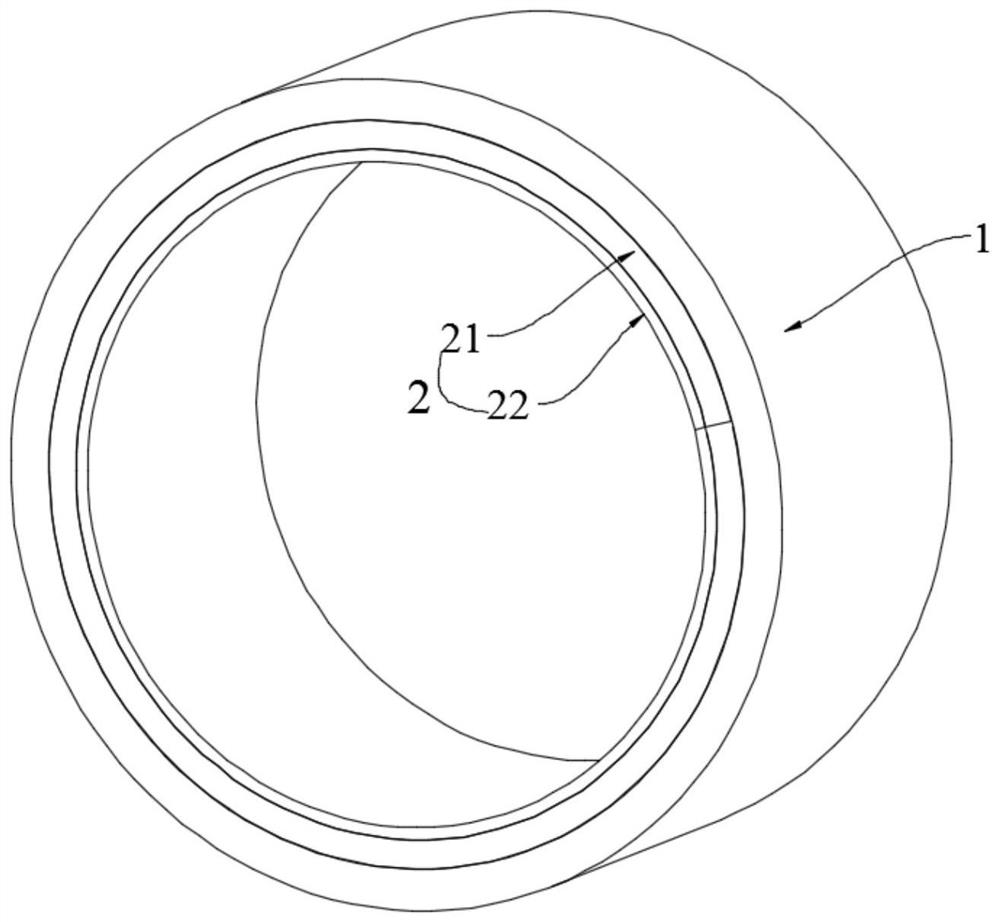

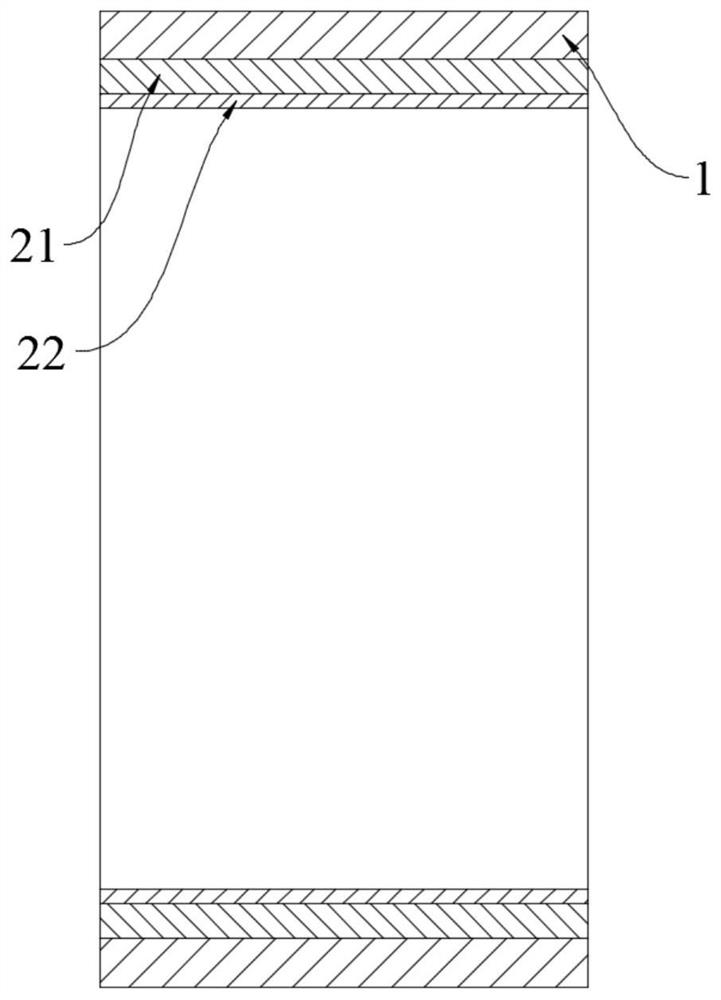

[0066] see Figure 1-Figure 2 As shown, the self-lubricating bearing of this embodiment includes an outer bushing 1 and an inner lining layer 2 installed in the outer bushing, and the inner lining layer 2 includes a metal substrate 21 and a fiber resin composite layer on the metal substrate 21 22. The fiber resin composite layer 22 is made of fiber fabric impregnated with epoxy resin-based composite material and cured by hot pressing. The epoxy resin-based composite material is composed of 60% epoxy resin binder and 40% friction self-lubricating material . The epoxy resin adhesive consists of 83% epoxy resin, 7% curing agent and 10% epoxy diluent. The friction self-lubricating material is composed of 30% graphite, 20% molybdenum disulfide (MoS 2 ) and 50% polytetrafluoroethylene (PTFE) powder composition.

[0067] The manufacturing method of self-lubricating bearing based on fiber fabric modification is as follows:

PUM

| Property | Measurement | Unit |

|---|---|---|

| friction coefficient | aaaaa | aaaaa |

| dispersion coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com