Self-fusing unit and protection element using self-fusing unit

A technology for protection components and protection devices, applied in electrical components, emergency protection devices, structural parts, etc., can solve the problem that the high resistivity of lead-containing and its alloy solder is difficult to meet the demand, and achieves reduction of on-resistance and contact resistance, Satisfy the effect of large current flow and high conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

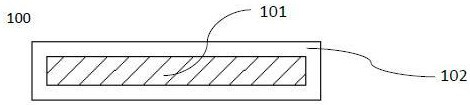

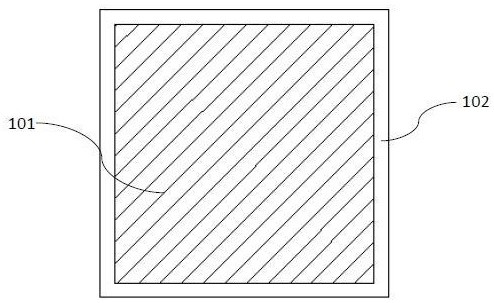

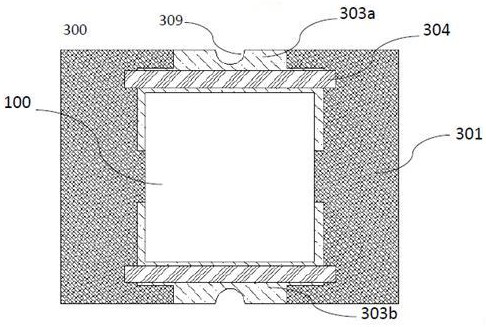

[0090] figure 1 is a schematic cross-sectional structure diagram of the self-fusing unit of the present invention; figure 2 is a schematic plan view of the self-fusing unit of the present invention.

[0091] A self-fusing unit 100 for protecting devices is a conductive sheath-core structure with a resistivity of 1.5-40 μΩ.cm, and the sheath-core structure includes an inner core 101 and an outer sheath 102, wherein the outer sheath 102 is in surface contact with the inner core 101 And fully coated on the periphery of the inner core 101, the surface of the inner core 101 is in contact with the outer sheath 102, the melting point and electrical conductivity of the outer sheath 102 are higher than the inner core 101, and the inner core 101 is a metal material or a polymer material, The outer sheath 102 is a silver-plated layer, which is used to inhibit the inner core material from swelling, deformation or melting out. In this embodiment, the outer sheath 102 adopts the preparati...

Embodiment 2

[0097] A self-fusing unit, such as figure 1 and figure 2 As shown, a core-sheath structure composed of an inner core 101 and an outer sheath 102, the inner core 101 is a metal material or a polymer material, and the outer sheath 102 is a silver-plated layer, and the outer sheath 102 of this embodiment adopts electroplating barrel plating silver The preparation method comprises the following steps in sequence:

[0098] In the first step, the material of the inner core 101 is made into a small-shaped substrate of 2.0*2.0*0.6mm by shearing or die stamping, and then placed in 80v% sulfuric acid aqueous solution at 40°C for 30 seconds. Deionized water cleaning, drying;

[0099] In the second step, put the SnCl of 15g / L of sensitizer 2 Sensitize in the solution for 200 minutes, take it out, wash it with deionized water, and dry it;

[0100] The third step, put the catalyst 0.1g / L of PdCl 2 Catalyze in the solution for 360 minutes, take it out, wash it with deionized water, dry...

Embodiment 3

[0103] A self-fusing unit, such as figure 1 and figure 2 As shown, a core-sheath structure composed of an inner core 101 and an outer sheath 102, the inner core 101 is a metal material or a polymer material, and the outer sheath 102 is a preparation method that combines calendering composite and electroplating barrel plating silver plating, in order Include the following steps:

[0104] In the first step, a 10 μm silver sheet is pasted on the upper and lower surfaces of the 0.6mm inner core 101, combined by calendering, shearing or die stamping, to make a small piece of 2.0*2.0, and then placed in a 40 Contact 80v% aqueous sulfuric acid solution at ℃ for 30 seconds, wash with deionized water, and dry;

[0105] In the second step, put sensitizer 15g / L SnCl 2 Sensitize in the solution for 200 minutes, take it out, wash it with deionized water, and dry it;

[0106] The third step, put the PdCl of catalyst 0.1g / L 2 Catalyze in the solution for 360 minutes, take it out, wash ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com