Reusable waterborne polyurethane shielding material and preparation method thereof

A technology for water-based polyurethane and masking materials, applied in the field of polyurethane materials, can solve the problems of non-reusable, difficult to handle, not environmentally friendly, etc., and achieve the effects of easy tearing, saving production materials, and reducing waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

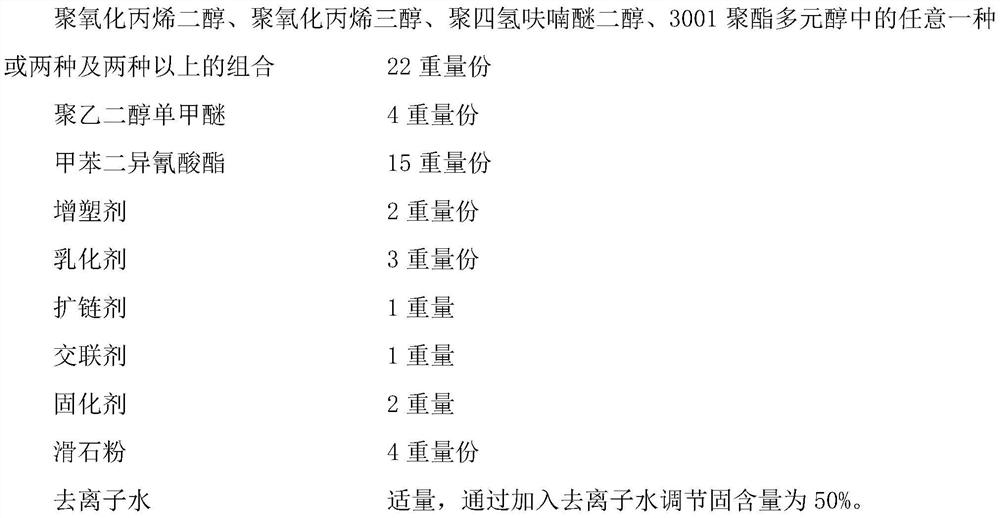

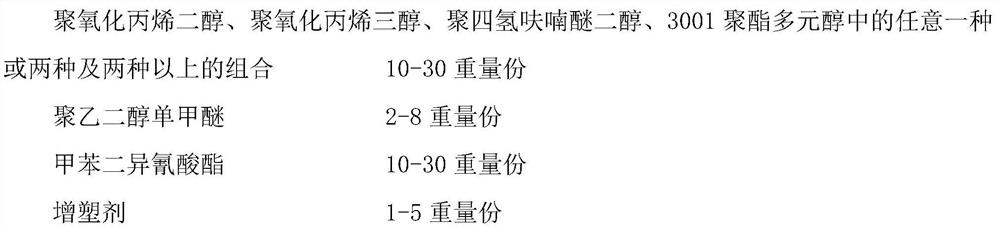

[0025] A reusable water-based polyurethane masking material comprises the following raw materials:

[0026]

[0027] Described plasticizer is dibutyltin dilaurate; Described emulsifier is dimethylolpropionic acid (DMPA), and described chain extender is ethylenediamine; Described linking agent is pentaerythritol, dipentaerythritol, triethanolamine (TEA) any one or a combination of two or more; the curing agent is isophorone diisocyanate, and the talcum powder is 1000 mesh.

Embodiment 2

[0029] A preparation method for reusable water-based polyurethane masking material, comprising the following steps:

[0030] Step S1. Accurately weigh 22 parts by weight of polytetrahydrofuran ether glycol and 2 parts by weight of plasticizer (dibutyltin dilaurate), place them in a reactor filled with nitrogen, and react under stirring at 75°C for 15 minutes;

[0031] Step S2, add 15 parts by weight of toluene diisocyanate, 3 parts by weight of emulsifier (dimethylolpropionic acid (DMPA)) and 2 parts by weight of curing agent (isophorone diisocyanate) in the reactor, and adjust the temperature of the water bath to 80°C, stir for 30min;

[0032] Step S3, adding 4 parts by weight of polyethylene glycol monomethyl ether, continuing to react for 1 hour, adding 1 part by weight of crosslinking agent (triethanolamine) and chain extender (ethylenediamine) dropwise, adding deionized water to adjust the solid content to 50%, continue to react for 1h, cool down;

[0033] Step S4, addi...

Embodiment 3

[0037] A preparation method for reusable water-based polyurethane masking material, comprising the following steps:

[0038] Step S1. Accurately weigh 15 parts by weight of 3001 polyester polyol and 1 part by weight of plasticizer (dibutyltin dilaurate), place them in a reactor filled with nitrogen, and react under stirring at 90°C for 15 minutes;

[0039] Step S2, add 10 parts by weight of toluene diisocyanate, 3 parts by weight of emulsifier (dimethylolpropionic acid (DMPA)) and 1 part by weight of curing agent (isophorone diisocyanate) in the reactor, and adjust the temperature of the water bath to 90°C, stirring for 40min;

[0040] Step S3, adding 3 parts by weight of polyethylene glycol monomethyl ether, continuing to react for 1 hour, then adding 1 part by weight of crosslinking agent (triethanolamine) and chain extender (ethylenediamine) dropwise, adding deionized water to adjust the solid content to 50%, continue to react for 1.5h, cool down;

[0041] Step S4, adding...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com