CMP pad MANUFACTURING METHOD AND CMP PAD Conditioner

A chemical machinery and manufacturing method technology, applied in semiconductor/solid-state device manufacturing, manufacturing tools, grinding/polishing equipment, etc., can solve the problems of coating corrosion, frequency increase, scratches, etc. The effect of expanding and reducing the size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] Hereinafter, embodiments of the present disclosure will be described with reference to the accompanying drawings.

[0048] The above and other aspects, features, and advantages of the present disclosure will become apparent from the detailed description of the following embodiments in conjunction with the accompanying drawings.

[0049] It should be understood that the present disclosure is not limited to the following embodiments and may be embodied in various ways, and the embodiments are provided to provide a complete disclosure of the present disclosure and to enable those skilled in the art to thoroughly understand the present disclosure. The scope of the present disclosure is defined only by the claims.

[0050] Descriptions of known functions and constructions that may unnecessarily obscure the subject matter of the present disclosure will be omitted.

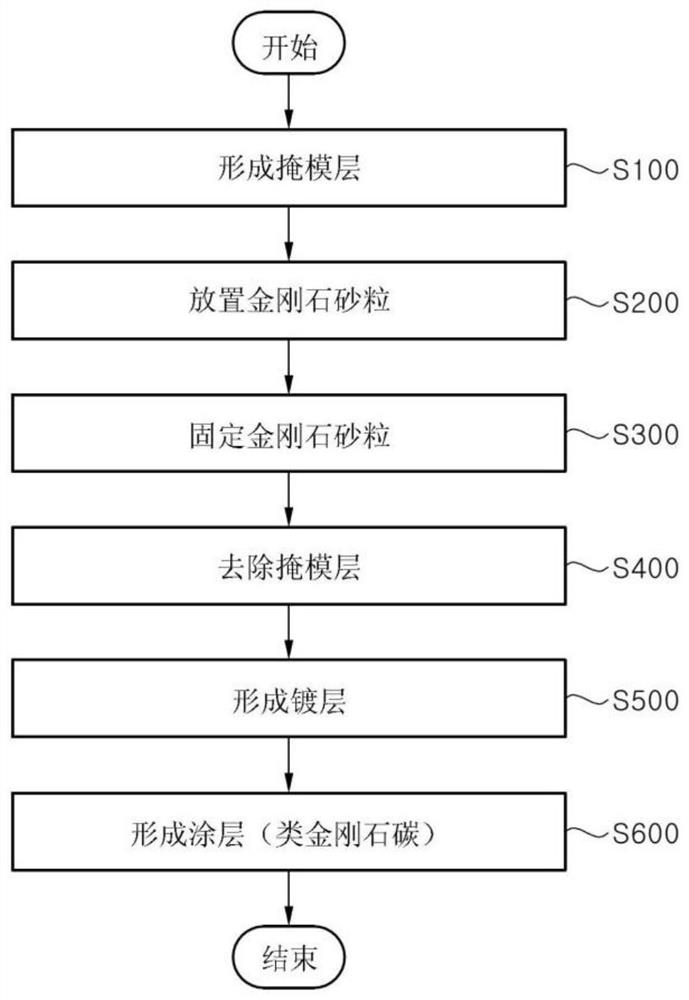

[0051] figure 1 is a flowchart of a method of manufacturing a CMP pad conditioner according to the present di...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com