Oil-resistant and corrosion-resistant heel logo material and preparation method thereof

A corrosion-resistant and heel technology, applied in the field of polymer materials, can solve the problems of affecting the aesthetics of shoes, poor oil resistance, and limiting heel marks, etc., and achieve good shape, strong oil resistance, and improved oil resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] Preparation of Graphene Oxide

[0049] The preparation method of described graphene oxide comprises the following steps:

[0050] s1: Add 15g of graphite powder to the first mixture containing 25ml of concentrated sulfuric acid, 10g of potassium persulfate and 10g of phosphorus pentoxide for pre-oxidation treatment, the treatment temperature is 80°C, and the treatment time is 6 hours; after the treatment, then Add deionized water for dilution, then filter, wash with water, and dry to obtain pre-oxidized graphite powder;

[0051] s2: Add 15g of pre-oxidized graphite powder and 50g of potassium permanganate into 450ml of concentrated sulfuric acid to form a second mixture for low-temperature reaction, the reaction temperature is 10°C, and the reaction time is 1h;

[0052] s3: Set the reaction temperature in S2 to 40°C for medium-temperature reaction, and the reaction time is 2 hours;

[0053]s4: Add 900ml of deionized water to the second mixture, and set the reaction te...

Embodiment 2

[0056] Preparation of modified graphene

[0057] Described modified graphene comprises following composition by weight:

[0058] 20 parts of graphene oxide;

[0059] 5 parts of polypropylene resin;

[0060] 2 parts modifier;

[0061] Described graphene oxide is made by embodiment 1;

[0062] The modifier is a mixture of 4,4'-bismaleimido-diphenylmethane and 2,2'-diallyl bisphenol A in a mass ratio of 2:1.

[0063] The preparation method of described modified graphene comprises the following steps:

[0064] Step 1: Prepare raw materials according to the set weight parts, add graphene oxide to absolute ethanol for ultrasonic dispersion for 1 hour, then add polypropylene resin particles to absolute alcohol, and then ultrasonically disperse for 1 hour, then remove the anhydrous Ethanol makes the third mixture; (wherein every 20g graphene oxide joins in 300ml dehydrated alcohol)

[0065] Step 2: Add the third mixture and modifier into an internal mixer for melt-blending treat...

Embodiment 3

[0067] Preparation of oil-resistant and corrosion-resistant heel standard material

[0068] An oil-resistant and corrosion-resistant heel standard material, comprising the following components by weight:

[0069] 50 parts of nitrile rubber

[0070] Neoprene 30 parts

[0071] 20 parts of natural rubber;

[0072] 2 parts stearic acid;

[0073] 7 parts of polyethylene glycol;

[0074] 3 parts sulfur;

[0075] Accelerator 5 parts;

[0076] 8 parts of compatibilizer

[0077] 8 parts of enhancer;

[0078] Anti-aging agent 2 parts.

[0079] The accelerator is (Z)-3-(2-bromo-3-(trifluoromethyl)styryl)-2,7-bis(trifluoromethyl)benzofuran, (E)-4- A mixture of (4-bromo-3-(trifluoromethyl)phenyl)-3-butenenitrile and ethylene oxide in a mass ratio of 2:2:1;

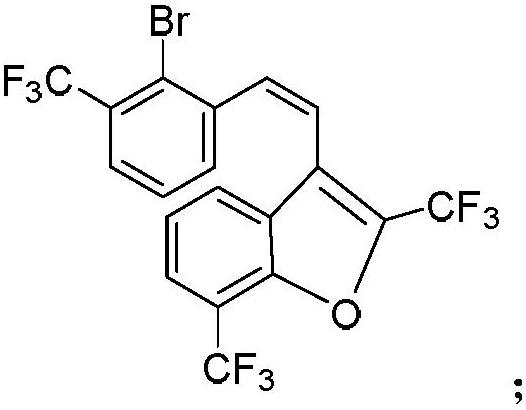

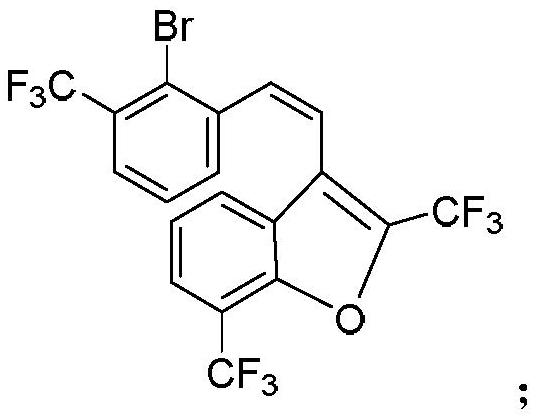

[0080] Wherein the structural formula of (Z)-3-(2-bromo-3-(trifluoromethyl)styryl)-2,7-bis(trifluoromethyl)benzofuran is

[0081]

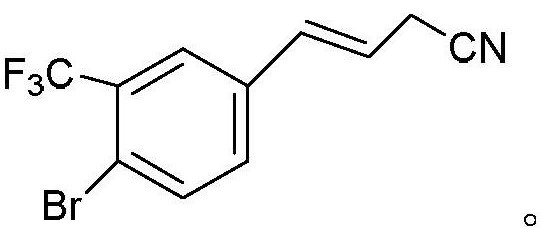

[0082] The structural formula of (E)-4-(4-bromo-3-(trifluoromethyl)phenyl)-3-butenenitril...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com