Copper/silver-based electrode taking conductive bacterial cellulose composite film as substrate

A bacterial cellulose and composite electrode technology, which is applied in battery electrodes, organic compound/hydride/coordination complex catalysts, circuits, etc., can solve the problem of inability to tightly combine catalysts and substrate materials, catalysts falling into electrolyte solutions, Inability to efficiently recombine catalysts and other issues to achieve the effects of improving Faradaic efficiency, improving utilization and conversion rates, and reducing the occurrence of hydrogen evolution reactions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

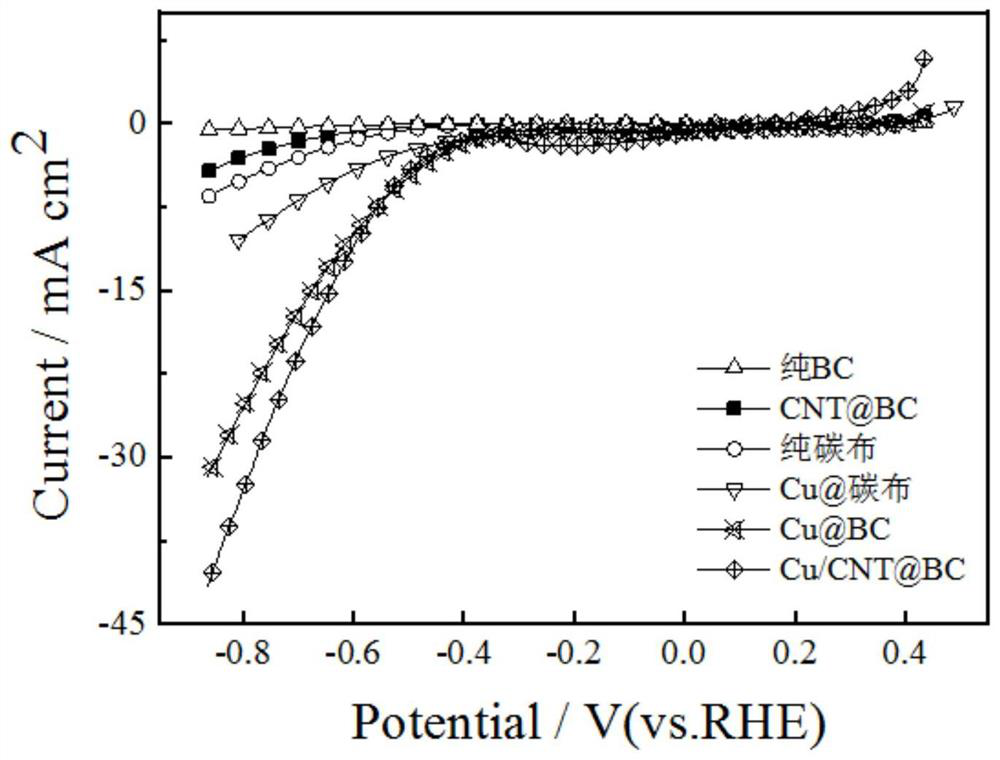

[0062] The copper-based electrode for electrochemical catalysis in this example is composed of a static in-situ cultured CNT@BC composite film loaded nano-copper electrode. The electrode is synthesized by an in-situ catalytic reduction method, and its preparation method is as follows:

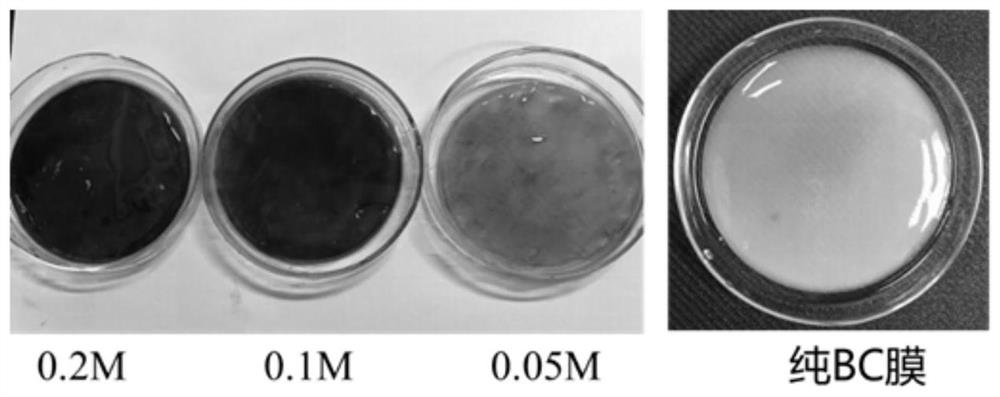

[0063] (1) With Acetobacter xylinum as the strain (Komagataeibacter xylinusATCC23770, the same below), adding molar concentrations of 0.05M, 0.1M, 0.2M carbon nanotubes (industrial grade multi-walled carbon nanotubes, >90%, inner diameter: 5- 15nm, outer diameter: >50nm, length: 10-20 μ m, 50g, Aladdin Reagent (Shanghai) Co., Ltd., other examples are the same) respectively with fermentation medium (50g / L glucose, C 6 h 12 o 6 , AR, Sinopharm Reagent Co., Ltd.; 5g / L tryptone, BR, Sinopharm Reagent Co., Ltd.; 3g / L yeast powder, BR, Sinopharm Reagent Co., Ltd., the same below) mixed solution (in-situ static constant temperature culture 2 -3 days, take out the CNT@BC composite membrane and place ...

Embodiment 2

[0076] The silver-based electrode used for electrochemical catalysis in this embodiment is composed of a CNT@BC composite film supported by a dynamic in-situ cultured nano-copper electrode. The electrode is synthesized by an in-situ catalytic reduction method, and its preparation method is as follows:

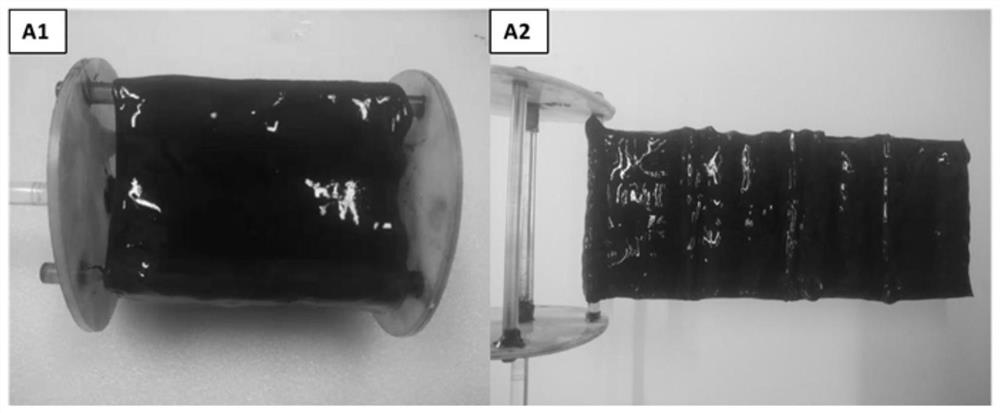

[0077] (1) With Acetobacter xylinum as the strain, add 200 mL of a mixed solution of carbon nanotubes and medium with a concentration of 0.1M in a horizontal drum reactor, add two drops of Tween 80 as a dispersant with a rubber dropper, and mix well Cultivate for 24h. In the aseptic workbench, continue to add 200ml of 0.1M CNT and fermentation broth mixed medium into the glass fermenter through a peristaltic pump for subsequent fermentation and culture for 24 hours. Take out the CNT@BC composite membrane and place it in sodium hydroxide solution, treat it at 80°C for 2-4 hours, take it out, rinse it with deionized water until neutral, and obtain the CNT@BC composite membrane. ...

Embodiment 3

[0083] The copper-based electrode used for electrochemical catalysis in this example is composed of impregnated and cultured CNT@BC composite film loaded nano-copper electrode. The electrode is synthesized by in-situ catalytic reduction method, and its preparation method is as follows:

[0084] (1) Use Acetobacter xylinum as the bacterial species, prepare bacterial cellulose pure film by static culture for 2-4 days, take out the pure film and place it in sodium hydroxide solution, treat it at 80°C for 2-4h, take it out, and use it The pure BC membrane was obtained after rinsing with deionized water to neutrality.

[0085] (2) The pure BC membrane was dynamically impregnated with a carbon nanotube aqueous solution with a concentration of 0.1M, oscillated dynamically in a constant temperature oscillator at 30°C for 24 hours, and the CNT@BC composite membrane was obtained after taking it out. Multi-walled carbon nanotubes can be dispersed for 30 minutes with an ultrasonic cleanin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com