Porous hollow RuP@PNC catalyst and preparing method and application thereof

A catalyst and hollow technology, applied in the direction of electrodes, electrolysis process, electrolysis components, etc., can solve the problems of unfavorable development and not many active sites

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

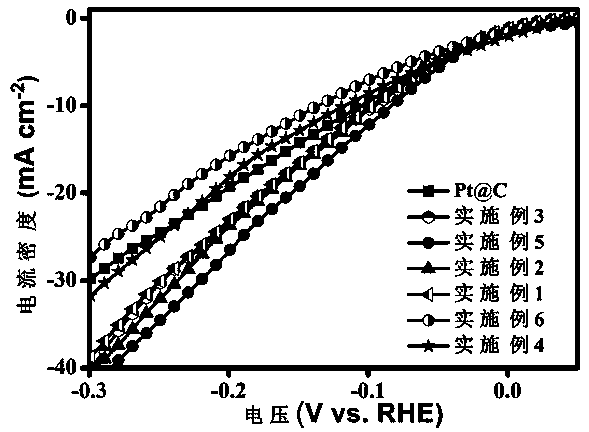

Examples

Embodiment 1

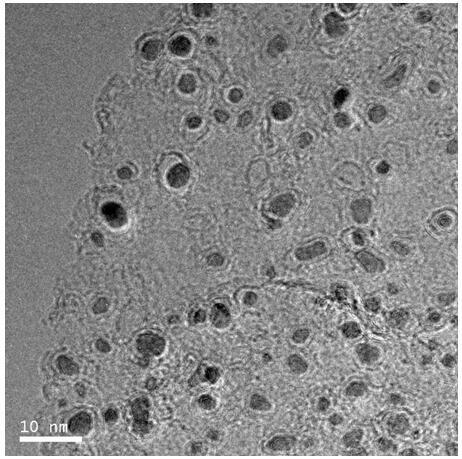

[0025] Example 1 Preparation of porous hollow RuP@PNC catalyst:

[0026] Weigh 112mg of ruthenium chloride, 13.3mg of ferric chloride and 1mL of phytic acid and dissolve them in a beaker with 30mL of water, add 1.6g of dicyandiamide, 40mg of glucose and 40mg of ammonium sulfate after stirring for 2 hours, and continue stirring for 12 hours After the liquid has to be mixed evenly, stop stirring.

[0027] Put the obtained homogeneous mixed liquid in a blast drying oven at 90°C for 12 hours to evaporate the moisture in the homogeneously mixed liquid to obtain a dry solid product. After grinding the obtained solid product evenly, put it into a crucible , the crucible was then placed in a tube furnace, and calcined in the tube furnace for 2 h in a nitrogen atmosphere at a calcination temperature of 800° C. to obtain a metal nanocatalyst. Add the obtained metal nano-catalyst to 40 mL of hydrochloric acid aqueous solution and stir for 1-2 days (the concentration of the hydrochloric ...

Embodiment 2

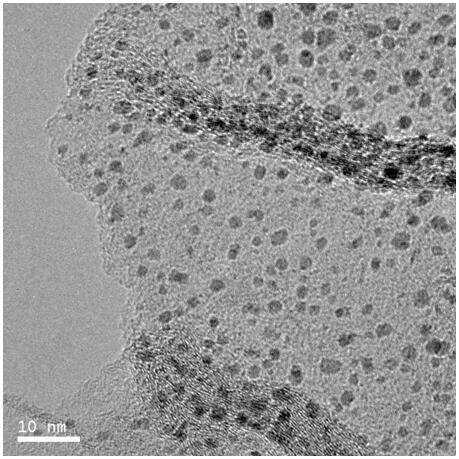

[0028] Example 2 Preparation of porous hollow RuP@PNC catalyst:

[0029] The ruthenium chloride that takes by weighing 11.2mg, the ferric chloride of 13.3mg and the phytic acid of 1mL are dissolved in the beaker that has 30mL water, add dicyandiamide 1.6g, glucose 40mg and ammonium sulfate 40mg after stirring 2h, continue stirring 12 After hours, the liquid has to be evenly mixed and the stirring is stopped.

[0030] Put the obtained homogeneous mixed liquid in a blast drying oven at 90°C for 12 hours to evaporate the moisture in the homogeneously mixed liquid to obtain a dry solid product. After grinding the obtained solid product evenly, put it into a crucible , the crucible was then placed in a tube furnace, and calcined in the tube furnace for 2 h in a nitrogen atmosphere at a calcination temperature of 800° C. to obtain a metal nanocatalyst. Add the obtained metal nano-catalyst to 40 mL of hydrochloric acid aqueous solution and stir for 1-2 days (the concentration of the...

Embodiment 3

[0031] Example 3 Preparation of hollow porous core RuP@PNC catalyst:

[0032] The ruthenium chloride that takes by weighing 22.2mg, the ferric chloride of 13.3mg and the phytic acid of 1mL are dissolved in the beaker that has 30mL water, add dicyandiamide 1.6g, glucose 40mg and ammonium sulfate 40mg after stirring 2h, continue stirring 12 After hours, the liquid has to be evenly mixed and the stirring is stopped.

[0033] Put the obtained homogeneous mixed liquid in a blast drying oven at 90°C for 12 hours to evaporate the moisture in the homogeneously mixed liquid to obtain a dry solid product. After grinding the obtained solid product evenly, put it into a crucible , the crucible was then placed in a tube furnace, and calcined in the tube furnace for 2 h in a nitrogen atmosphere at a calcination temperature of 800° C. to obtain a metal nanocatalyst. Add the obtained metal nano-catalyst to 40 mL of hydrochloric acid aqueous solution and stir for 1-2 days (the concentration o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com