Preparation method of graphite surface in-situ graphenized and Pt-supported electrocatalysis hydrogen evolution catalyst

A graphene and electrocatalytic technology, applied in the field of electrocatalytic hydrogen evolution, can solve the problems of mild conditions, process energy consumption, high synthesis temperature, etc., and achieve the effect of mild conditions, low cost and stable catalyst

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] A method for preparing a Pt electrocatalytic hydrogen evolution catalyst supported by in-situ graphene on a graphite surface, comprising the following steps:

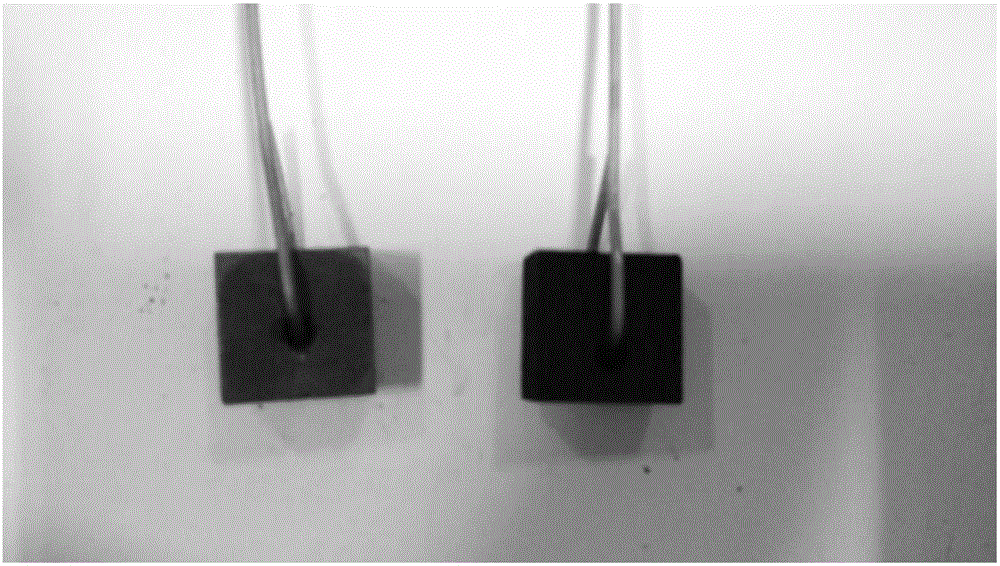

[0038] (1) Cut the graphite plate into graphite blocks with a size of 1.0*1.0*0.5cm, punch holes in the graphite block, and use a titanium wire with a diameter of 0.8mm to connect the electrodes as wires. Place the graphite block in 1.0 mol / L HCl, deionized water, 1.0 mol / L NaOH and deionized water for 1 hour to ultrasonically clean the surface of the graphite block, dry it naturally, and mark it as GP.

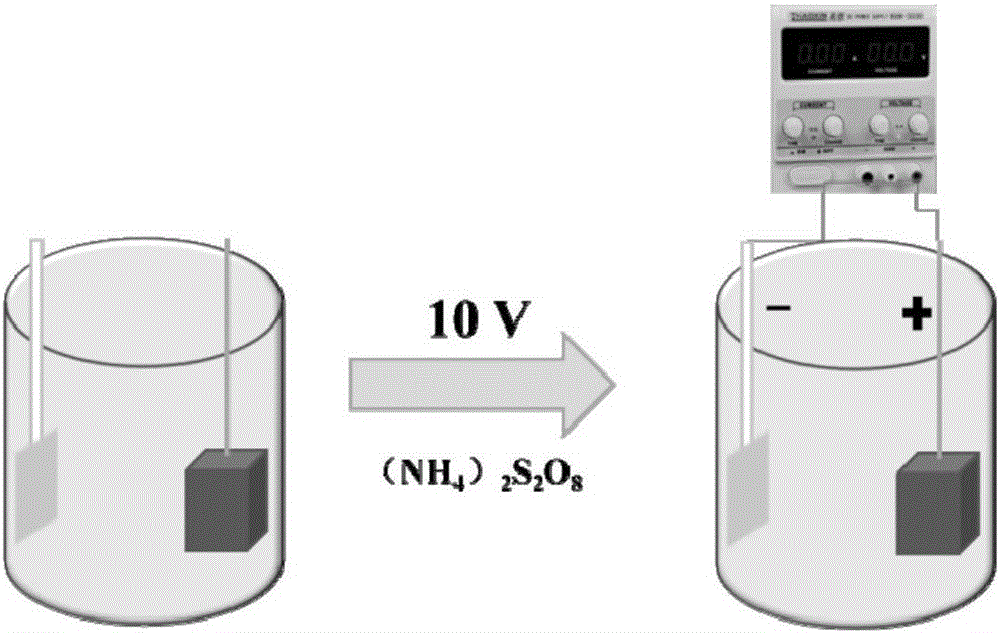

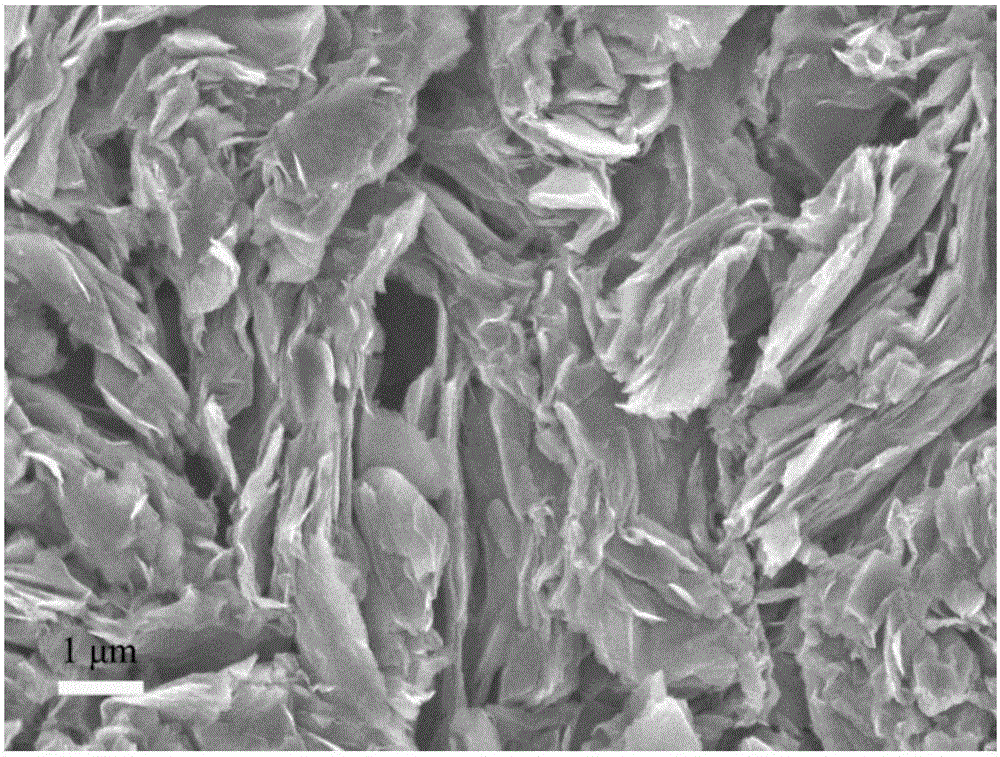

[0039] (2) With the pretreated graphite block as the positive electrode and the platinum sheet as the negative electrode, connect the potentiostat, set the voltage to 10V, and electrolyze in 0.3mol / L ammonium persulfate solution for 300s. After electrolysis, rinse the surface of the electrode with deionized water, dry it naturally, and mark it as GL / GP-300.

[0040] (3) With the graphite block after electrolyti...

Embodiment 2

[0042] As described in Example 1, the difference is: the electrolysis time in step (2) in Example 1 is changed to 30s, and the rest are the same as Example 1. The electrode material obtained in step (2) is denoted as GL / GP-30, and the finally obtained electrode material is denoted as Pt-GL / GP-30A. The hydrogen evolution overpotential of GL / GP-30 is -492mV, and that of Pt-GL / GP-30A is -218mV.

Embodiment 3

[0044] As described in Example 1, the difference is: the electrolysis time in step (2) in Example 1 is changed to 60s, and the rest are the same as Example 1. The finally obtained electrode material is denoted as Pt-GL / GP-60A. The hydrogen evolution overpotential of Pt-GL / GP-60A is -208mV.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com