Long nozzle replacement method and equipment based on visual servo, terminal and medium

A technology of visual servoing and replacement methods, which is applied in the direction of casting equipment, metal processing equipment, manufacturing tools, etc., can solve the problems of high risk, high temperature, and inability to realize automation, etc., and achieves simple and easy implementation, automation, and practicability and high applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

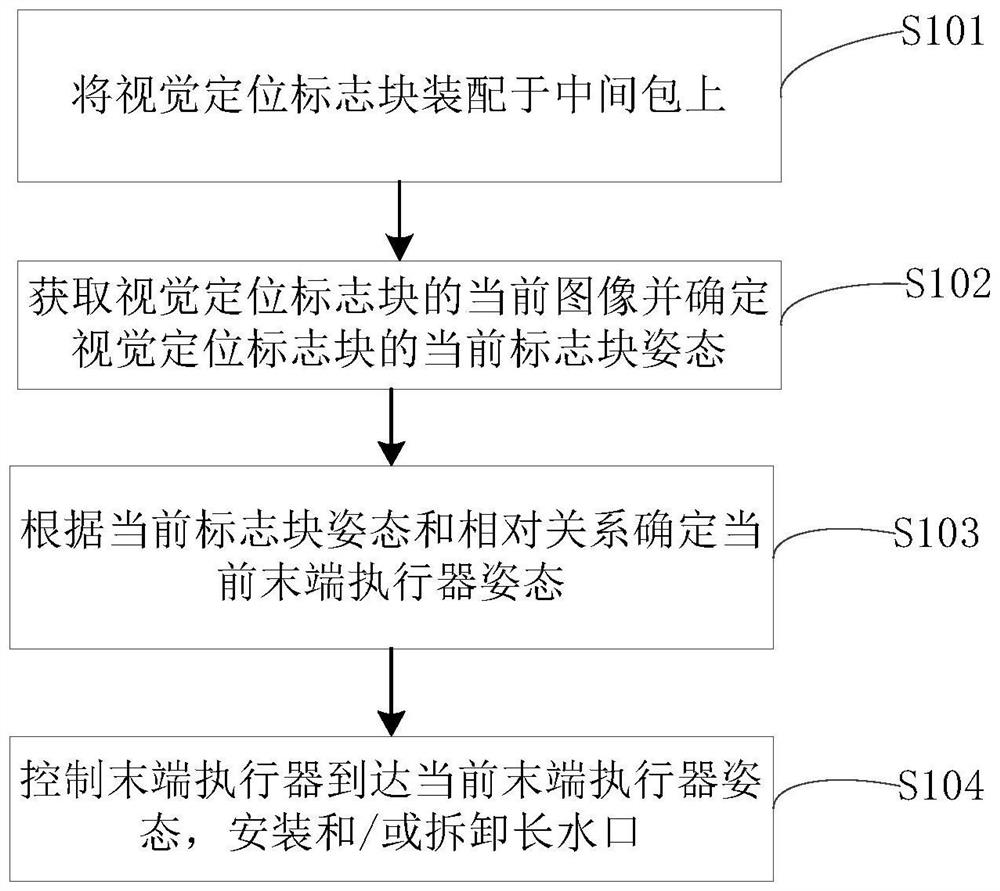

[0054] see figure 1 , the embodiment of the present invention provides a method for replacing a shroud based on visual servoing, including:

[0055] S101: Assembling the visual positioning mark block on the tundish.

[0056] In some embodiments, the visual positioning marker block is fixedly installed on the slide mechanism of the continuous casting tundish.

[0057] In some embodiments, the visual positioning marker block includes at least 3 different sub-marker blocks.

[0058] In some embodiments, the visual positioning sign block includes at least two background color backgrounds, and the current background color background of the visual positioning sign block is determined according to the on-site background color background. Optionally, the outline shapes of the sub-markers are the same, and the sizes of the sub-markers are different.

[0059] Optionally, the size of each sub-marker block can be adjusted according to actual working conditions, which is not limited her...

Embodiment 2

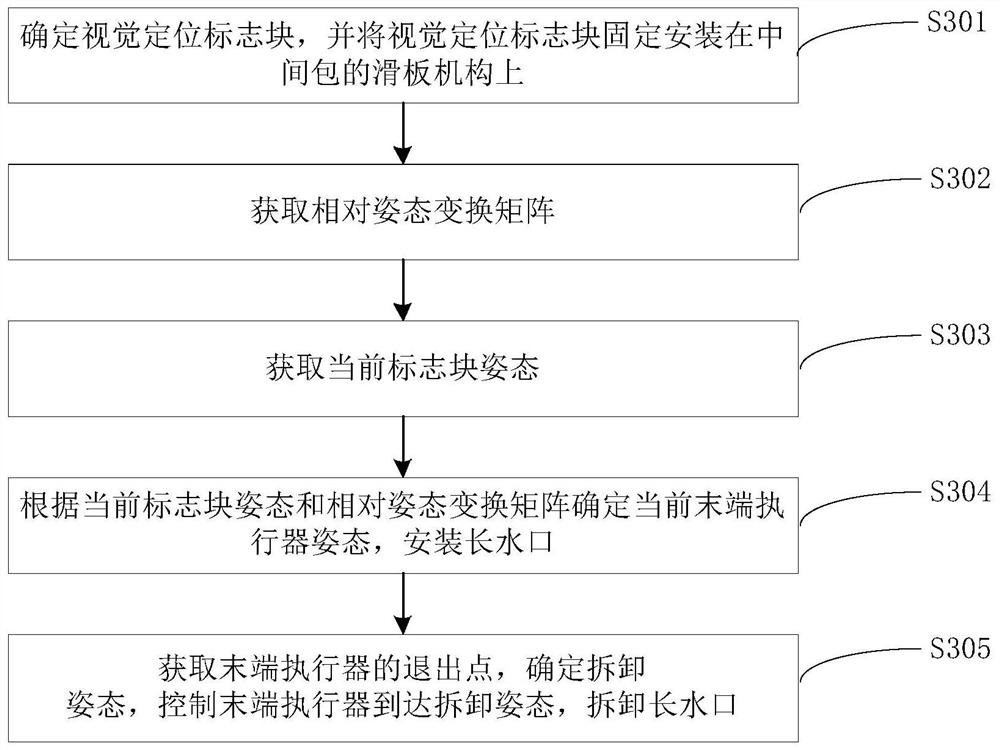

[0132] The method for replacing a long shroud based on visual servoing provided by this embodiment is exemplarily described below through a specific embodiment, see: image 3 , the specific method for replacing the long shroud based on visual servoing includes:

[0133] S301: Determine the visual positioning mark block, and fix the visual positioning mark block on the sliding plate mechanism of the tundish.

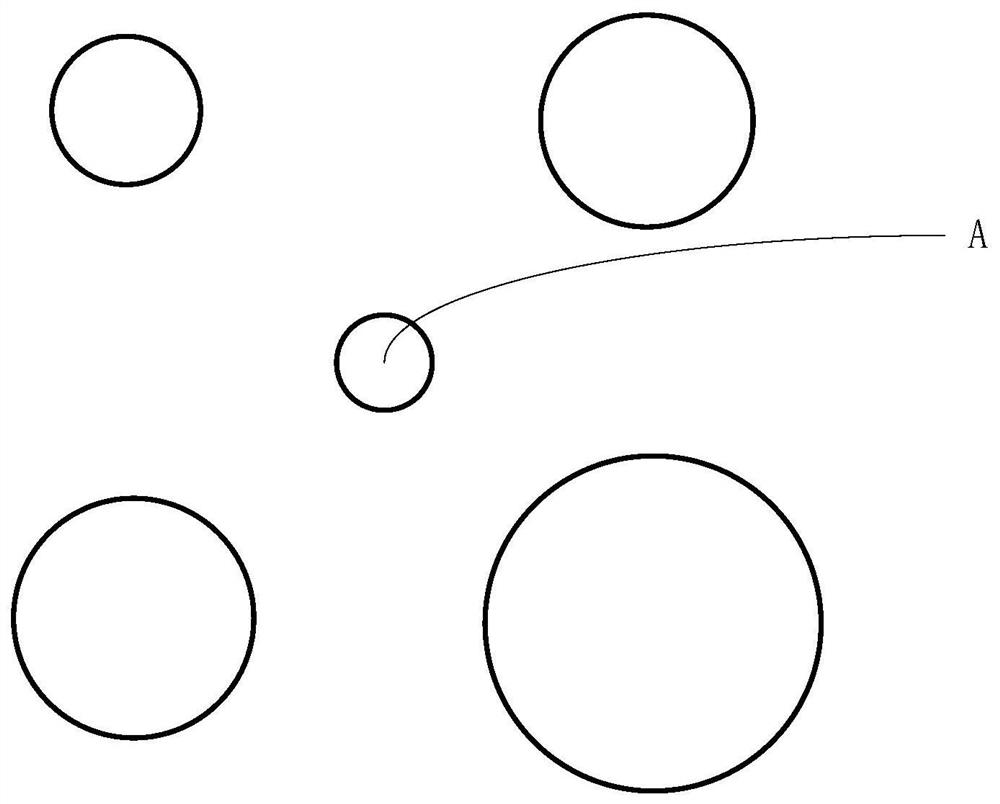

[0134] In some embodiments, the outline of the visual locator block is a circular outline.

[0135] Optionally, the background color, background, shape and size of the visual positioning marker block and the radius of the circle outline can be determined according to the on-site environment. After the design and processing of the visual positioning marker block is completed, the relative positional relationship between the centers of the circle outlines is recorded.

[0136] In some embodiments, the schematic diagram of the structure of each sub-marker block on the visua...

Embodiment 3

[0165] see Figure 4 , a shroud replacement device 400 based on visual servoing, comprising:

[0166] An assembly module 401, configured to assemble the visual positioning marker block on the tundish;

[0167] The current marker block posture acquisition module 402 is used to acquire the current image of the visual positioning marker block and determine the current marker block posture of the visual positioning marker block;

[0168] A determining module 403, configured to determine the current end effector pose according to the current marker block pose and the relative relationship, the relative relationship including a mapping between the marker block pose and the end effector pose;

[0169] The control module 404 is used to control the end effector to reach the current end effector attitude, and install and / or remove the shroud.

[0170] In this embodiment, the shroud replacement device based on visual servoing is essentially equipped with a plurality of modules to execu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com