Negative electrode binder for lithium-ion battery, preparation method of negative electrode binder and lithium-ion battery containing negative electrode binder

A technology of lithium-ion batteries and binders, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of poor electrochemical stability and poor mechanical properties of binders, and achieve good mechanical properties and electrical Chemical stability, strong adhesive force, effect of small amount of addition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

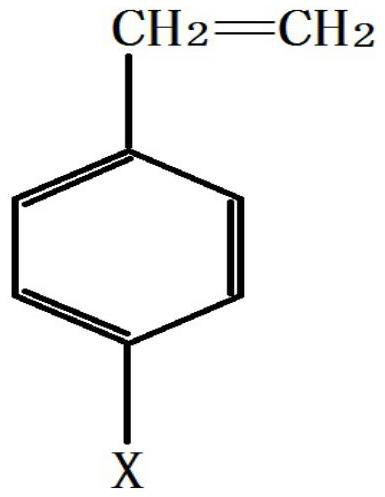

Image

Examples

Embodiment 1

[0031] The seed emulsion comprises the following components and parts by weight thereof:

[0032] Deionized water: 250 parts; Sodium alkyl sulfate: 1 part; Sodium alkyl sulfonate: 1 part; Sodium p-styrene sulfonate: 2 parts; Sodium persulfate: 0.4 parts; 4-F-styrene: 85 parts; Acrylonitrile: 5 parts; acrylic acid: 0.2 parts; n-dodecanethiol: 0.5 parts.

[0033] The preparation method of the seed emulsion is: after the polymerization tank is evacuated, add deionized water, sodium alkyl sulfate, sodium alkyl sulfonate, sodium p-styrene sulfonate, sodium persulfate, start stirring and heat up to 70 ° C, drop Add a mixture of 4-F-styrene, acrylonitrile, acrylic acid and n-dodecanethiol to carry out free radical emulsion polymerization. The reaction time is 3 hours. The temperature is raised to 90°C and kept for 0.5 hours. After cooling, the seed emulsion is obtained by filtering. .

[0034] Negative electrode binder for lithium ion battery comprises following components and part...

Embodiment 2

[0047] The seed emulsion comprises the following components and parts by weight thereof:

[0048] Deionized water: 289 parts; Sodium alkylsulfonate: 3 parts; Sodium alkylbenzenesulfonate: 2 parts; Sodium p-styrenesulfonate: 3 parts; Sodium acrylamidoisopropylsulfonate: 2 parts; Ammonium: 1 part; 4-Cl-styrene: 95 parts; n-butyl acrylate: 10 parts; isobutyl acrylate: 5 parts; maleic acid: 1 part;

[0049] The preparation method of the seed emulsion is: after the polymerization kettle is evacuated, add deionized water, sodium alkylsulfonate, sodium alkylbenzenesulfonate, sodium p-styrenesulfonate, sodium acrylamido isopropylsulfonate, persulfuric acid Ammonium, start stirring and heat up to 90°C, add dropwise the mixture of 4-Cl-styrene, n-butyl acrylate, isooctyl acrylate, maleic acid, and tert-dodecyl mercaptan to carry out free radical emulsion polymerization, and the reaction time is After 6 hours, the temperature was raised to 90° C. for 0.5 hour, and after cooling, the see...

Embodiment 3

[0060] The seed emulsion comprises the following components and parts by weight thereof:

[0061] Ionized water: 255.5 parts; Sodium alkylbenzene sulfonate: 2 parts; Sodium alkylphenol ether sulfosuccinate: 1.5 parts; Sodium alkyl sulfosuccinate allyl succinate: 2 parts; Sodium sulfonate: 1.5 parts; potassium persulfate: 0.7 parts; 4-Br-styrene: 90 parts; methyl acrylate: 10 parts; methacrylic acid: 0.6 parts;

[0062] The preparation method of the seed emulsion is: after the polymerization tank is evacuated, add deionized water, sodium alkylbenzene sulfonate, sodium alkylphenol ether sulfosuccinate, sodium alkyl allyl succinate sulfonate, alkyl acrylic acid -2-Sodium ethanesulfonate, potassium persulfate, start stirring and heat up to 80°C, dropwise add the mixture of 4-Br-styrene, methyl acrylate, methacrylic acid, n-butyl mercaptan to carry out free radical emulsion polymerization, The reaction time is 4.5 hours, the temperature is raised to 90° C. for 0.5 hours, and the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com