Visible antibacterial breathable anti-fog film and preparation method thereof

A film and anti-fog technology, applied in the field of packaging films, can solve the problems of increasing moisture permeability and decreasing film transparency, and achieve the effects of inhibiting proliferation, preserving the shelf life of fresh food, and simplifying preparation operations.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

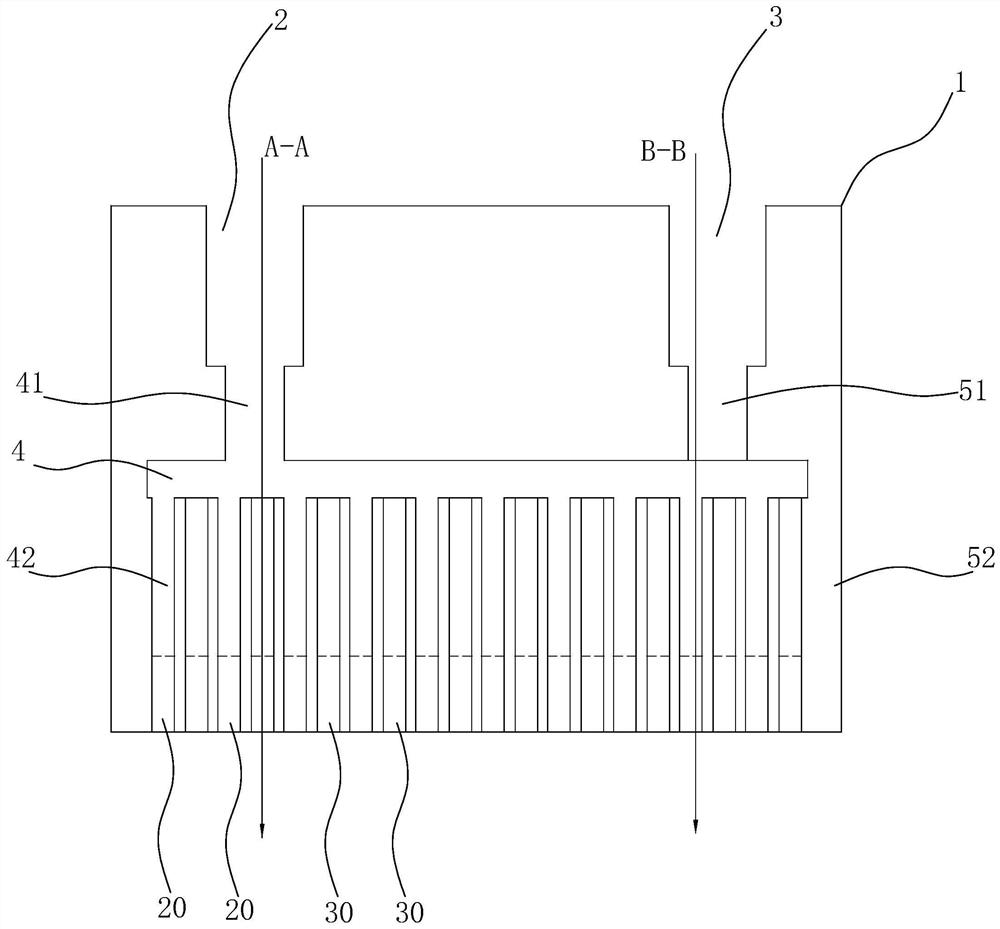

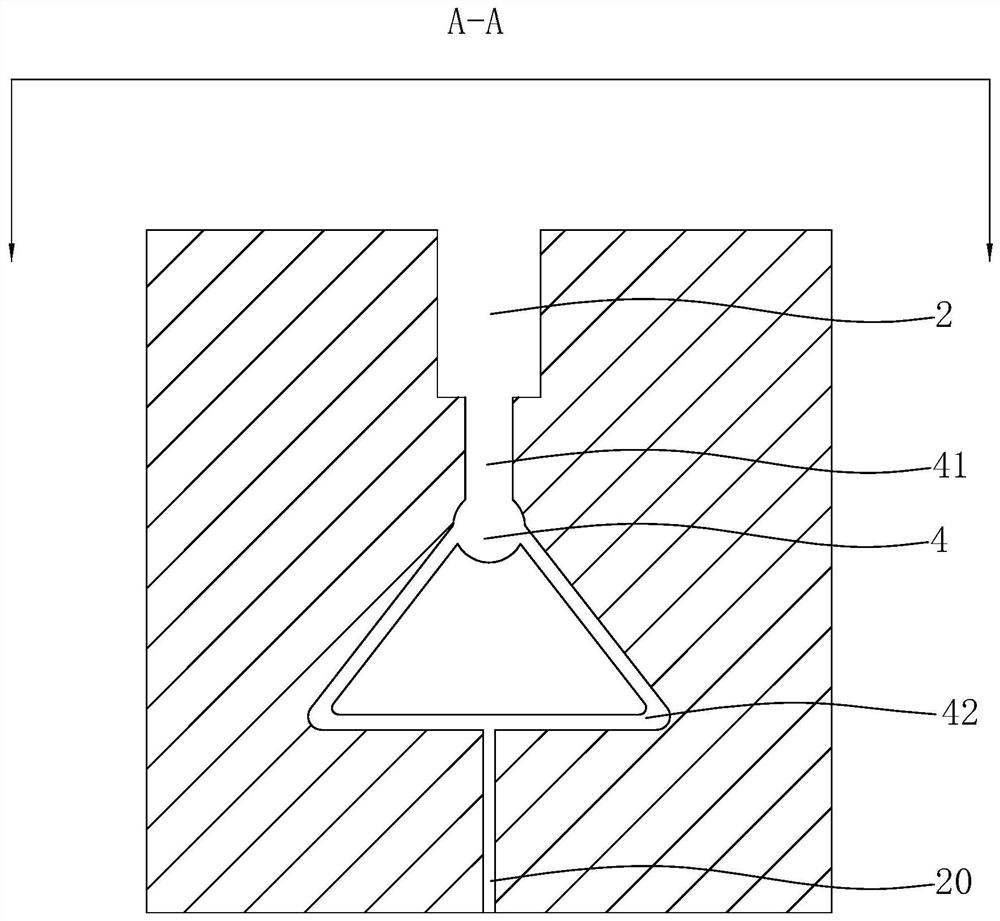

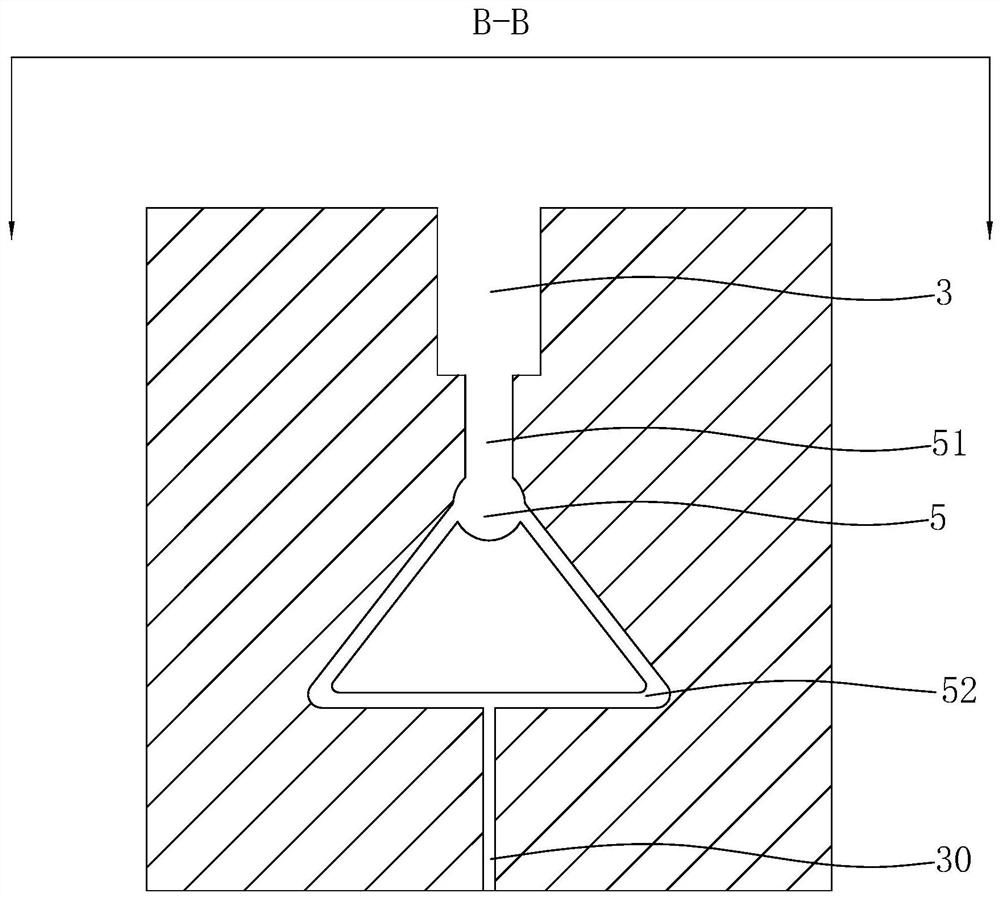

Image

Examples

preparation example 1

[0054] Surface treatment of inorganic fillers:

[0055] 1. Use an ion implanter to perform ion implantation on calcium carbonate of model JKGX-A1. The acceleration voltage is 50Kv. The accelerated ion beam passes through the magnetic analyzer of the ion implanter. The ion selected by the magnetic analyzer from the ion beam bombards the calcium carbonate Calcium target surface; then the calcium carbonate obtained through the above operations is mixed with Silquest A-187 silane coupling agent for surface modification to obtain modified calcium carbonate.

[0056] 2. The 4A molecular sieve is screened by ball milling to obtain 4A molecular sieve powder with a particle size of 4 μm. The ion implanter is used to implant 4A molecular sieve powder with an accelerating voltage of 50Kv. The accelerated ion beam passes through the magnetic analyzer of the ion implanter. The ions selected by the analyzer from the ion beam bombard the target surface of the 4A molecular sieve powder; then ...

preparation example 2

[0059] Preparation of anti-fog masterbatch: linear low density polyethylene, tripolyglycerol monostearate, and authentic BASF polyethylene wax emulsion are blended at a mass percentage of 60%:30%:10%, and extruded at a temperature of 204°C. Granulate.

preparation example 3

[0061] Preparation of antibacterial masterbatch: linear low density polyethylene, sodium dehydroacetate, and calcium propionate are blended at a mass percentage of 60%:30%:10%, extruded at a temperature of 205°C, and granulated.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com