Preparation method and application of super-hydrophobic composite membrane material

A composite membrane, super-hydrophobic technology, applied in the coating and other directions, can solve the problems of rust and corrosion of metal materials, food deterioration and decay, and the surface of the substrate becoming wet, achieving a short process, easy control of operation, and simple and easy preparation method Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Wet the nickel foam in toluene, and then burn it in the air atmosphere to obtain a carbon-deposited composite film; then immerse it at a concentration of 0.5g L -1 The hexane solution of perfluorooctyltripolysilane was taken out and dried naturally in air to obtain a superhydrophobic composite membrane material.

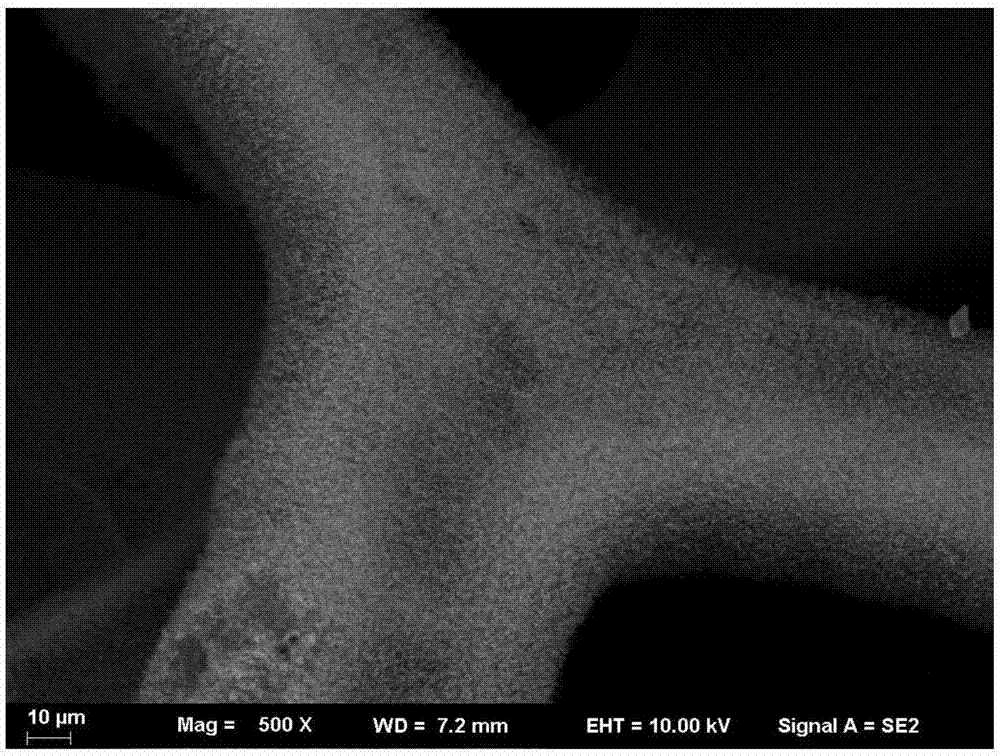

[0028] figure 1 The medium carbon is uniformly deposited on the surface of nickel foam, forming a fluffy nano-particle morphology.

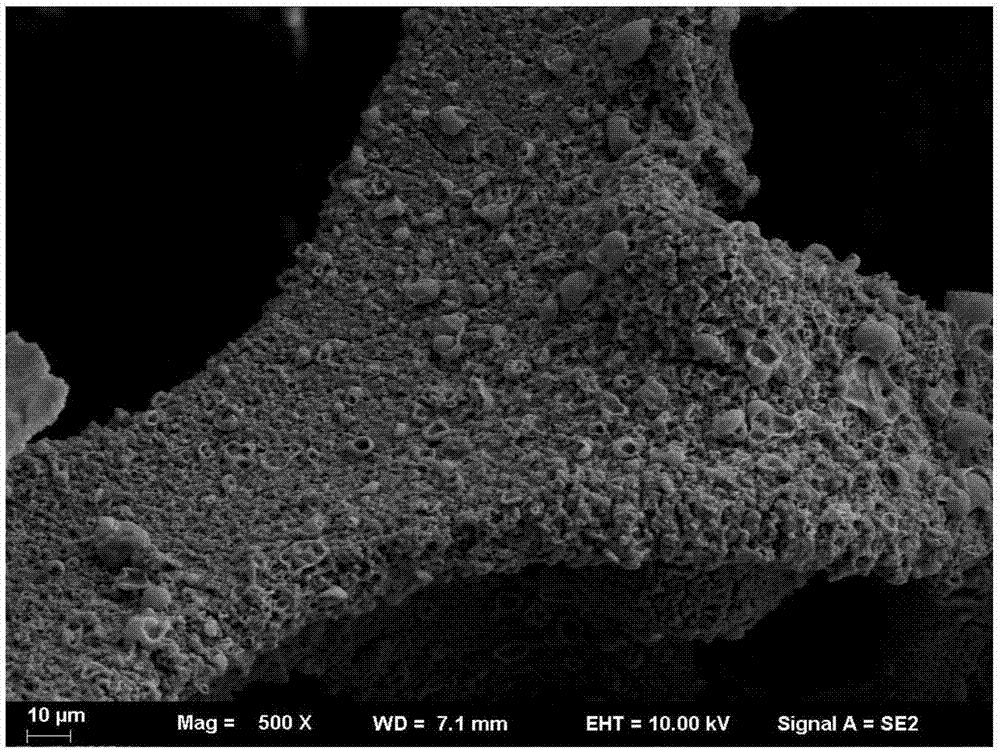

[0029] figure 2 The scanning electron microscope image showing the super-hydrophobic composite membrane material. It can be seen that the surface morphology and figure 1 Quite different, with a large number of micro-nano structures. It shows that the modification of low surface energy substances is very successful.

Embodiment 2

[0031] Wet the copper grid in benzene, and then burn it in the air atmosphere to obtain a carbon-deposited composite film; then immerse it at a concentration of 0.1g L -1 The hexane solution of perfluorodecyltrichlorosilane was taken out and naturally dried in air to obtain a superhydrophobic composite membrane material.

Embodiment 3

[0033] Wet the stainless steel mesh in hexane, and then burn it in the air atmosphere to obtain a carbon-deposited composite film; then immerse it at a concentration of 50g L -1 The hexane solution of perfluorodecyltrimethoxysilane was taken out and naturally dried in air to obtain a superhydrophobic composite membrane material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com