Wear-resistant self-lubricating anti-icing and anti-fog coating and preparation method thereof

An anti-fog coating and self-lubricating technology, which is applied in the direction of fireproof coatings, powder coatings, polyamide coatings, etc., can solve the problems of impact resistance, scratch resistance, toughness, etc. that are not very good, affect the appearance, and scratch the coating. Achieve good dispersibility, improve the effect of anti-icing, delay or frost formation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

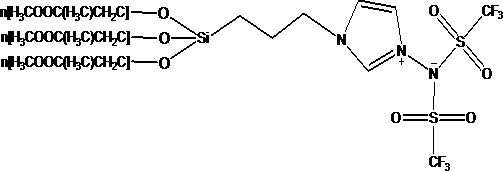

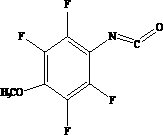

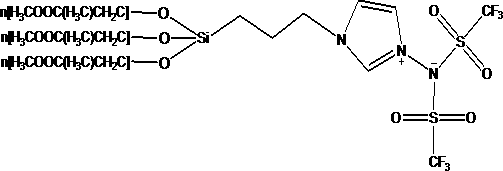

[0039] Take 50 parts of compound shown in Formula 1, 40 parts of polyamide resin, 15 parts of fluorophenylisocyanate curing agent shown in Formula 2, 2 parts of Gemini quaternary ammonium salt, 3 parts of polyethylene wax, 15 parts of filler, 1 part of defoamer 1 part and leveling agent 1 part.

[0040] Wherein, n in the compound shown in Formula 1 is 7; the end group of the polyamide resin is carboxyl group, the molecular weight is 3000-6000g / mol, the melting point is 135-145°C, and the melt viscosity is not higher than 450Pa·s at 165°C; The gemini quaternary ammonium salt is 12-3-12 type Gemini gemini quaternary ammonium salt; the defoamer is methyl silicone oil; the leveling agent is polyacrylate leveling agent.

[0041] The filler includes graphite, nano-alumina and modified nano-silicon dioxide, and the mass ratio of the three is 3:5:8. The modified nano-silicon dioxide is prepared by the following method: mixing nano-silicon dioxide Mix silicon oxide, ethanol, and ethyl...

Embodiment 2

[0047] Take 60 parts of compound shown in formula 1, 45 parts of polyamide resin, 20 parts of fluorophenyl isocyanate curing agent shown in formula 2, 4 parts of gemini quaternary ammonium salt, 5 parts of polyethylene wax, 18 parts of filler, 1.5 parts of defoamer 1.5 parts and leveling agent.

[0048]Wherein, n in the compound shown in Formula 1 is 5; the end group of the polyamide resin is carboxyl group, the molecular weight is 3000-6000g / mol, the melting point is 135-145°C, and the melt viscosity is not higher than 450Pa·s at 165°C; The gemini quaternary ammonium salt is 12-3-12 type Gemini gemini quaternary ammonium salt; the defoamer is simethicone; the leveling agent is a fluorine-containing acrylate leveling agent.

[0049] The filler includes graphite, nano-alumina and modified nano-silicon dioxide, and the mass ratio of the three is 6:6:11. The modified nano-silicon dioxide is prepared by the following method: mixing nano-silicon dioxide Mix silicon oxide, ethanol,...

Embodiment 3

[0055] Take 70 parts of compound shown in Formula 1, 50 parts of polyamide resin, 25 parts of fluorophenylisocyanate curing agent shown in Formula 2, 5 parts of Gemini quaternary ammonium salt, 6 parts of polyethylene wax, 20 parts of filler, 2 parts of defoamer 2 parts and 2 parts of leveling agent.

[0056] Wherein, n in the compound shown in Formula 1 is 3; the terminal group of the polyamide resin is carboxyl group, the molecular weight is 3000-6000g / mol, the melting point is 135-145°C, and the melt viscosity is not higher than 450Pa·s at 165°C; The gemini quaternary ammonium salt is a 12-3-12 type Gemini gemini quaternary ammonium salt; the defoamer is simethicone; the leveling agent is a silicone leveling agent.

[0057] The filler includes graphite, nano-alumina and modified nano-silicon dioxide, and the mass ratio of the three is 7:8:15. The modified nano-silicon dioxide is prepared by the following method: mixing nano-silicon dioxide Mix silicon oxide, ethanol, and e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com