Method for preparing SiO2 aerogel with nanometer apertures under normal pressure

An aerogel and nanopore technology, applied in the fields of silica, bulk chemical production, silicon oxide, etc., can solve the problems of reduced thermal conductivity of products, high cost, long cycle time, etc. Low cost and good hydrophobicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

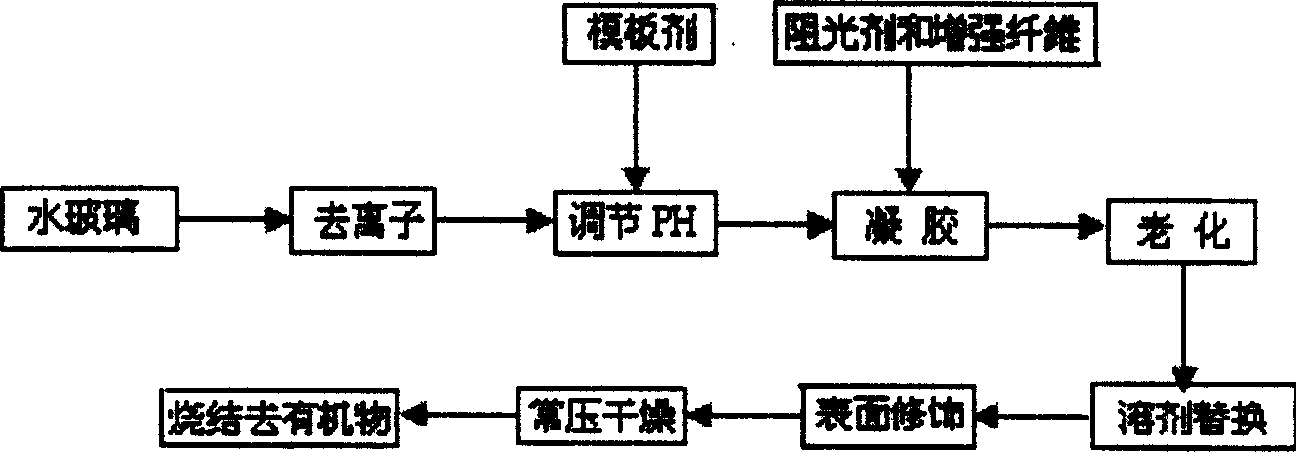

Method used

Image

Examples

Embodiment Construction

[0021] 1. Add in the order of water glass, sulfuric acid, water, glycerin and n-butylamine. Water glass / sulfuric acid=0.7~1 (molar ratio), the fixed pH value is about 8 to form a gel, and the aging time is generally 4~8 hours. Aging the above-mentioned colloid for several days, washing with water, then washing with ethanol several times, then washing with n-hexane, and finally washing with n-hexane and TMCS, filtering, and then drying in a drying oven at constant temperature, calcining to remove organic matter, and obtaining a nanoporous structure SiO 2 airgel.

[0022] 2. Add in the order of water glass, formamide, acetic acid, water, ethylene glycol, n-butylamine, water glass / formamide = 0.6~1 (molar ratio). Wherein water comprises the water in the water glass. The order of addition is to add water to water glass, then add diluted formamide, then add acetic acid and templating agent and stir for a few minutes. Dry at room temperature, then put in a drying oven to dry at ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com