Cu-Fe-Cr-Mg electromagnetic shielding material and preparation method thereof

A cu-fe-cr-mg, electromagnetic shielding material technology, applied in the direction of magnetic field / electric field shielding, electrical components, etc., can solve the problem of restricting the processing deformation ability of Cu-Fe alloy, prone to liquid phase separation, shrinkage cavity and porosity, etc. problems, achieve low price, suppress segregation, and improve quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0041] The present application also provides a method for preparing the above-mentioned Cu-Fe-Cr-Mg electromagnetic shielding material, comprising the following steps in sequence:

[0042] 1) Ingredients: according to the ratio of ingredients, the raw materials are pure iron, Cu-Cr master alloy, pure magnesium and pure copper;

[0043]2) Melting: Melting in a vacuum furnace, put the prepared pure copper and pure iron into the melting crucible in the vacuum furnace, put the pure magnesium and Cu-Cr intermediate alloy on the feeding tray in the vacuum furnace, and then Close the furnace cover and vacuumize. After the vacuuming is completed, fill it with argon for protection. The melting temperature is 1400°C~1450°C, and the holding temperature is 1330°C~1370°C. After holding for 10min~20min, add pure magnesium and Cu-Cr intermediate alloy. Keep warm for another 3 minutes to 5 minutes;

[0044] 3) Casting: Cast in the vacuum furnace in step 2), set the casting crucible in the el...

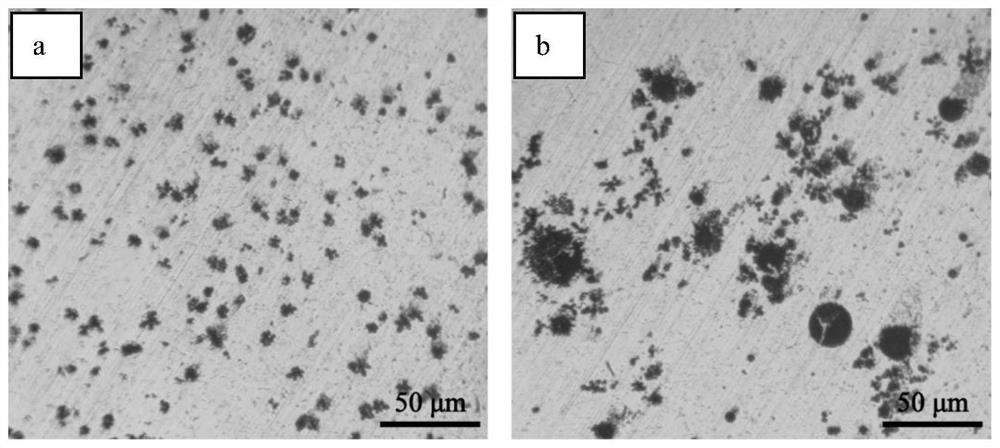

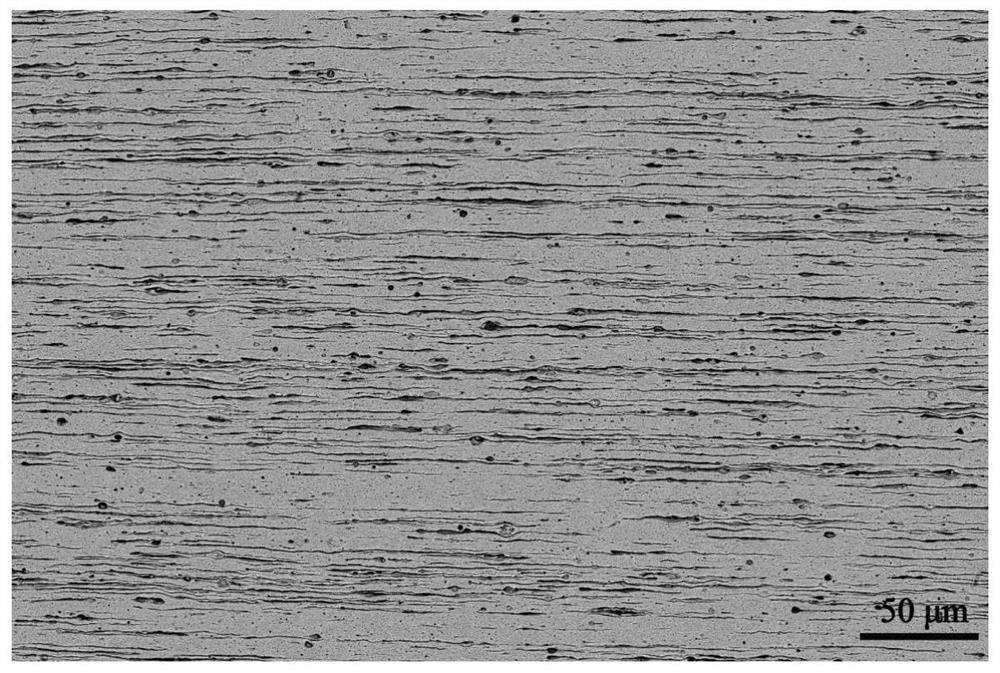

Embodiment 1

[0061] Embodiment 1 provides a kind of Cu-Fe-Cr-Mg electromagnetic shielding material, comprises the component of following mass percent: the Fe of 15wt%, the Cr of 0.5wt%, the Mg of 0.5wt%, balance is Cu and unavoidable of impurities.

[0062] The preparation method of the Cu-Fe-Cr-Mg electromagnetic shielding material provided in the above-mentioned embodiment 1 includes the following steps in sequence:

[0063] 1) Ingredients: according to the ratio of ingredients, the raw materials are pure iron, Cu-Cr master alloy, pure magnesium and pure copper;

[0064] In step 1), the mass percent purity of the pure copper, pure iron and pure magnesium is 99.95wt%, and the mass percent of chromium in the Cu-Cr master alloy is 5%;

[0065] 2) Melting: Melting in a vacuum furnace, put the prepared pure copper and pure iron into the melting crucible in the vacuum furnace, put the pure magnesium and Cu-Cr intermediate alloy on the feeding tray in the vacuum furnace, and then Close the fu...

Embodiment 2

[0079] Embodiment 2 provides a kind of Cu-Fe-Cr-Mg electromagnetic shielding material, comprises the component of following mass percentage: the Fe of 7wt%, the Cr of 0.3wt%, the Mg of 0.3wt%, balance is Cu and unavoidable of impurities.

[0080] The preparation method of the Cu-Fe-Cr-Mg electromagnetic shielding material provided in the above-mentioned embodiment 2 includes the following steps in sequence:

[0081] 1) Ingredients: according to the ratio of ingredients, the raw materials are pure iron, Cu-Cr master alloy, pure magnesium and pure copper;

[0082] In step 1), the mass percent purity of the pure copper, pure iron and pure magnesium is 99.95wt%, and the mass percent of chromium in the Cu-Cr master alloy is 5%;

[0083] 2) Melting: Melting in a vacuum furnace, put the prepared pure copper and pure iron into the melting crucible in the vacuum furnace, put the pure magnesium and Cu-Cr intermediate alloy on the feeding tray in the vacuum furnace, and then Close the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com