A kind of production technology of heat-resistant iron oxide black

A technology of iron oxide black and production process, which is applied in the field of chemical pigments, can solve problems such as fading, discoloration, and limiting the use range of iron oxide black, and achieve the effect of improving temperature resistance and dispersibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

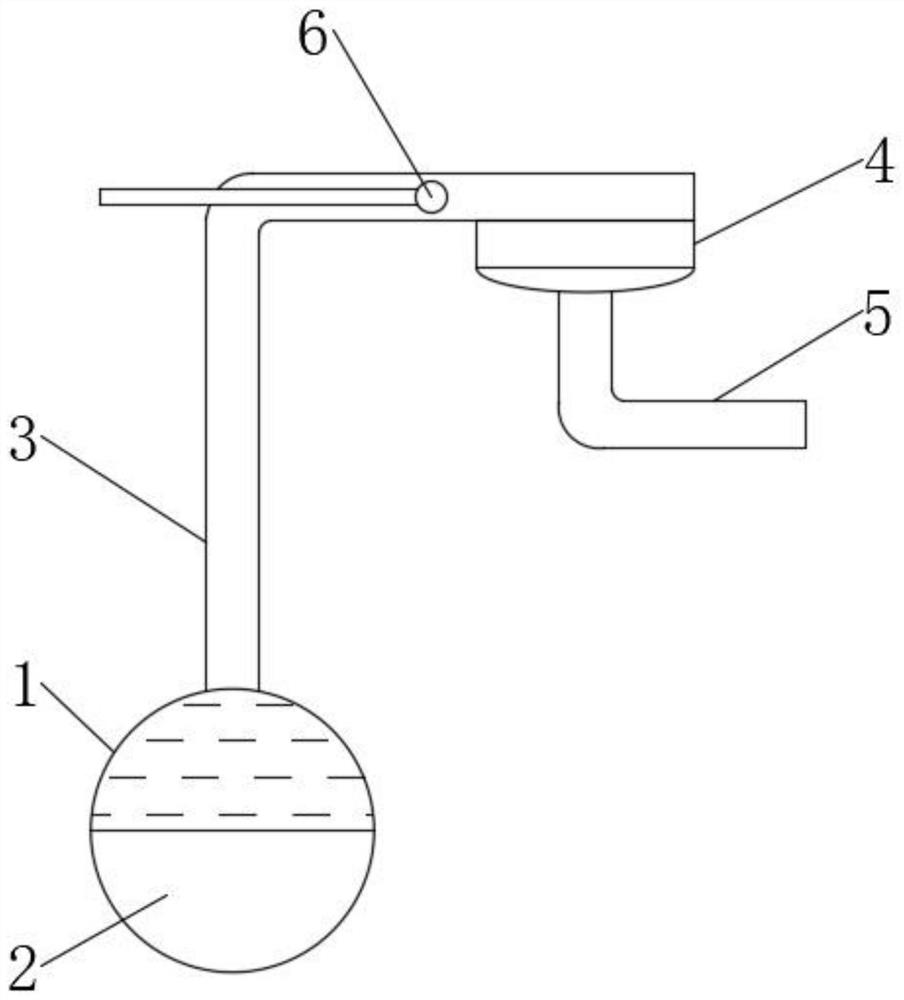

[0043] see Figure 1-2 , a production process of heat-resistant iron oxide black, a production process of heat-resistant iron oxide black, comprising the following steps:

[0044] S1, after filtering the solution prepared by the sodium hydroxide oxidation method to the raw material, enter the filter press to filter, and the solid is iron oxide black filter cake;

[0045] S2. Dehydrating and drying the iron oxide black filter cake above at 80° C., and pulverizing the dried iron oxide black pigment to obtain a primary powder of 50 mesh to 80 mesh;

[0046] S3, take the white carbon black of 5% of the weight of the primary powder and mix it with the powdered refractory material, and disperse at a high speed of 1500rpm for 15min;

[0047] S4. Take excess absolute ethanol and heat it to 80°C to obtain ethanol vapor, and mix it with surfactant and coupling agent sequentially in the entraining device;

[0048] S5. Drain the mixed steam to the mixed powder for covering impact, and l...

Embodiment 2

[0060] see Figure 1-2 , a production process of heat-resistant iron oxide black, a production process of heat-resistant iron oxide black, comprising the following steps:

[0061] S1, after filtering the solution prepared by the sodium hydroxide oxidation method to the raw material, enter the filter press to filter, and the solid is iron oxide black filter cake;

[0062] S2. Dehydrating and drying the iron oxide black filter cake above at 100° C., and pulverizing the dried iron oxide black pigment to obtain a primary powder of 50 mesh to 80 mesh;

[0063] S3, take the white carbon black of 6% of the powder weight of the first product and mix with the powdery refractory material, and disperse at a high speed of 1800rpm for 20min;

[0064] S4. Take excess absolute ethanol and heat it to 80°C to obtain ethanol vapor, and mix it with surfactant and coupling agent sequentially in the entraining device;

[0065] S5. Drain the mixed steam to the mixed powder for covering and impact...

Embodiment 3

[0074] see Figure 1-2 , a production process of heat-resistant iron oxide black, a production process of heat-resistant iron oxide black, comprising the following steps:

[0075] S1, after filtering the solution prepared by the sodium hydroxide oxidation method to the raw material, enter the filter press to filter, and the solid is iron oxide black filter cake;

[0076] S2. Dehydrating and drying the iron oxide black filter cake above at 150° C., and pulverizing the dried iron oxide black pigment to obtain a primary powder of 50 mesh to 80 mesh;

[0077] S3, take the white carbon black of 8% by weight of the primary powder and mix it with the powdered refractory material, and disperse at a high speed of 2000rpm for 20min;

[0078] S4. Take excess absolute ethanol and heat it to 80°C to obtain ethanol vapor, and mix it with surfactant and coupling agent sequentially in the entraining device;

[0079] S5. Drain the mixed steam to the mixed powder for covering and impacting, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com