Device for controlling Fe < 2 + > concentration in phosphating solution

A phosphating solution and concentration technology, which is applied in the coating process of metal materials, etc., can solve the problems of violent chemical reaction, waste of production efficiency, and deposition of phosphating slag on the workpiece, so as to reduce the concentration of Fe2+ and ensure stability , to avoid the effect of quality problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

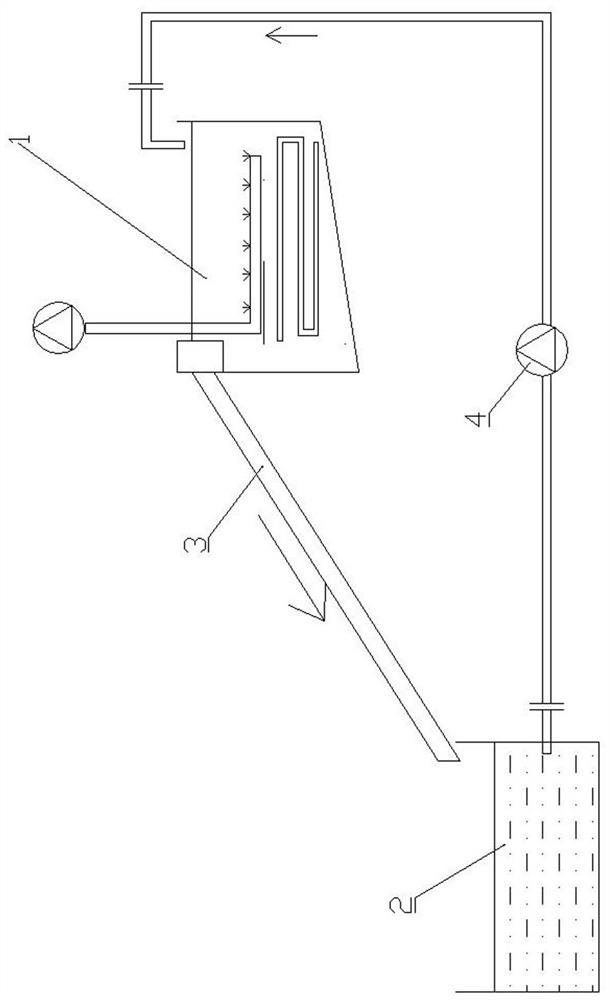

[0014] like figure 1 As shown, a phosphating solution controls Fe 2+ Concentration device, including oxidation reaction device 1, phosphating tank body 2, overflow pipe 3 and pumping device 4, the oxidation reaction device is used to remove Fe in the oxidized phosphating solution 2+ , the oxidized phosphating solution flows into the phosphating tank through the overflow pipe, and the phosphating tank contains Fe 2+ The phosphating solution flows into the oxidation reaction device through the pumping device; that is, the overflow port of the oxidation reaction device is connected to the water inlet of the phosphating tank through the overflow pipe, and the water outlet at the bottom of the phosphating tank is connected to the oxidation reaction device through the pumping device. Water port connection;

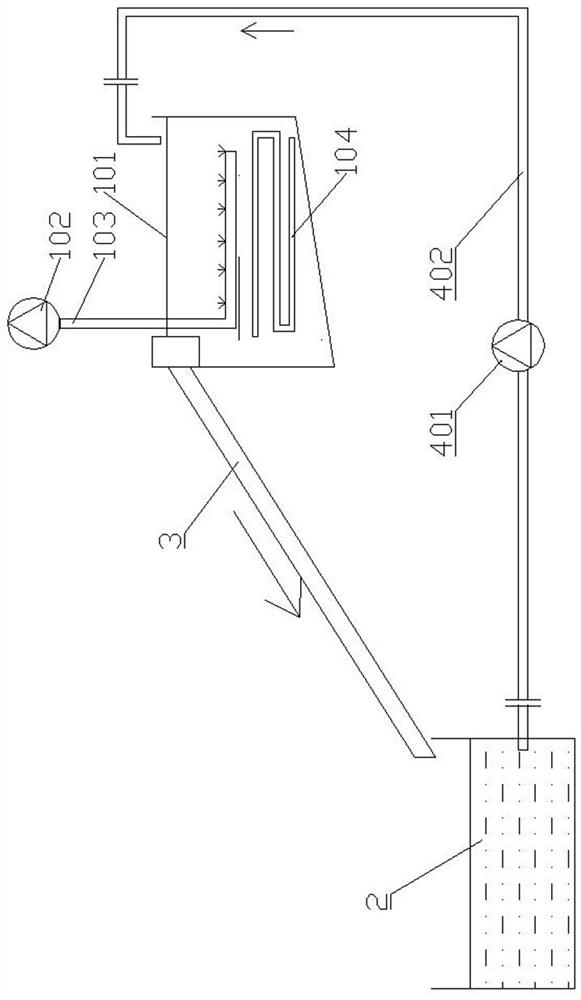

[0015] like figure 2 As shown, the oxidation reaction device 1 includes an oxidation tank body 101, an oxygen generator and a heater, the oxidation tank body, the oxygen gen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com