Preparation method of energetic thermoplastic elastomer compound

A technology of thermoplastic elastomers and composites, applied in the field of energetic materials, can solve the problems of affecting the mechanical properties of GAP-ETPE, increasing the glass transition temperature of GAP-ETPE, and not improving the mechanical properties of GAP-ETPE, etc., achieving low cost and easy preparation The method is easy and the effect of delaying the thermal decomposition temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

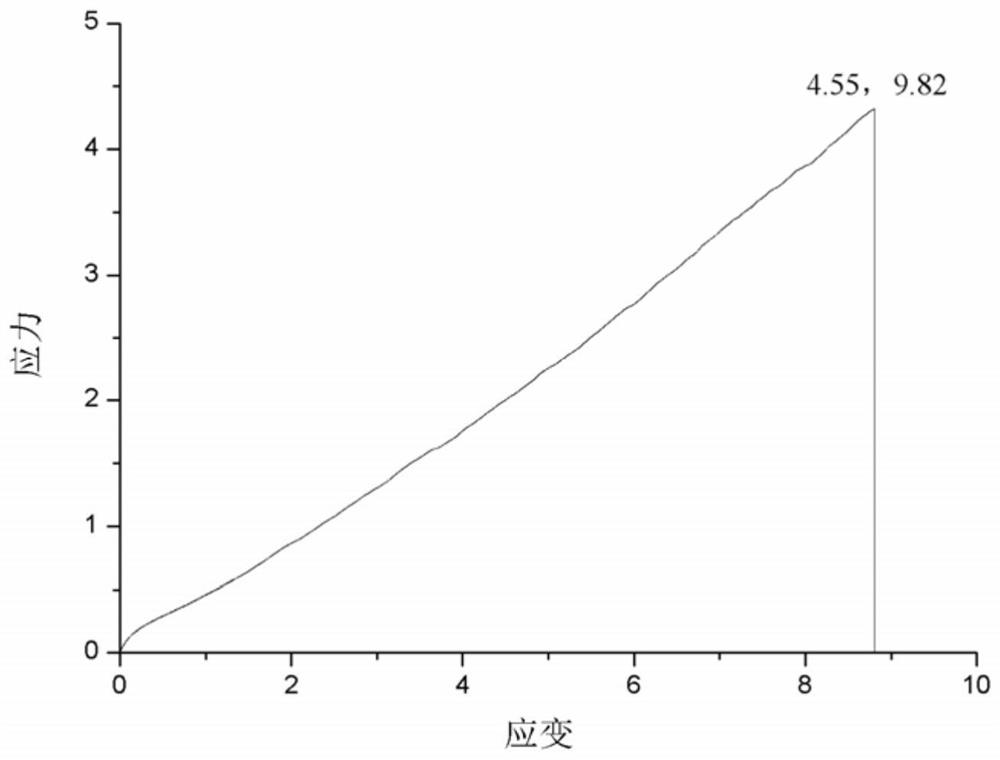

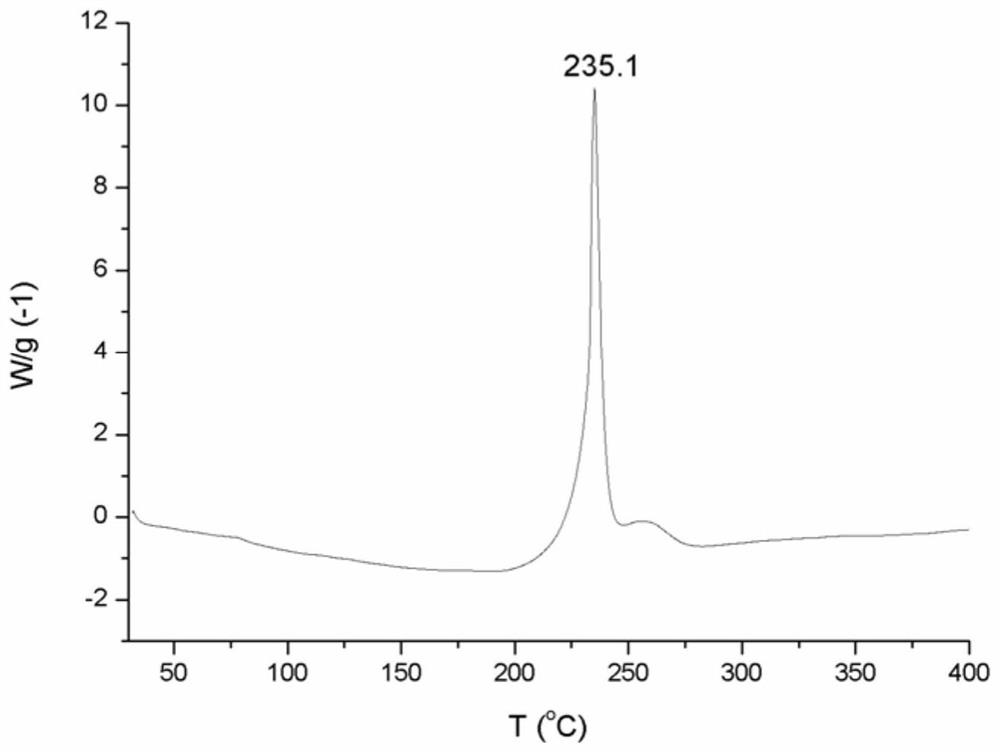

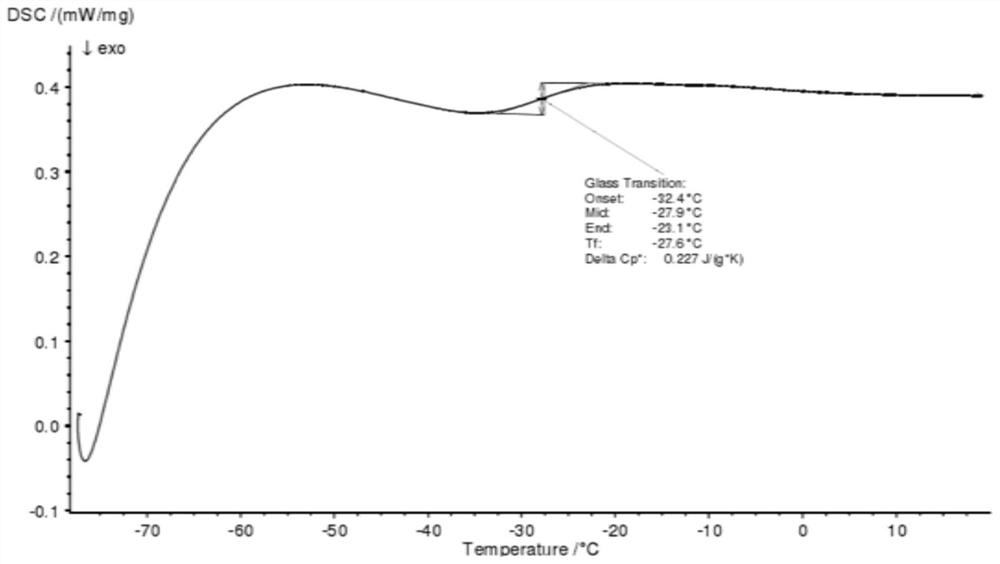

[0042] Add 20mg of 3-aminopropyltriethoxysilane-modified graphene oxide into 60g of tetrahydrofuran, ultrasonically disperse at 25°C for 1.5h, add 4.0g of GAP-ETPE into 100g of tetrahydrofuran, stir at 23°C for 1.5h, wait for GAP - The ETPE is completely dissolved; pour the amino-functionalized graphene oxide dispersion into the GAP-ETPE solution, stir the system at 30°C for 1 hour, and pour it into the mold after being uniform. After standing at room temperature for 2 weeks, it was dried at 35° C. for 3.0 h to obtain 4.0 g of the corresponding amino-functionalized graphene oxide / polyazide glycidyl ether-based energetic thermoplastic elastomer (GAP-ETPE) composite. The stress of the amino-functionalized graphene oxide / GAP-ETPE composite is 7.51MPa, which is 2.96MPa higher than that of GAP-ETPE, the strain is 12.31, which is an increase of 2.52, and the thermal decomposition temperature is 240.1℃, which is 5.0℃ higher than that of GAP-ETPE. The glass transition temperature is -...

Embodiment 2

[0051] Add 60mg of 3-aminopropyltriethoxysilane-modified graphene oxide into 150g of tetrahydrofuran, ultrasonically disperse at 35°C for 2.0h, add 6.0g of GAP-ETPE into 200g of tetrahydrofuran, stir at 34°C for 2.0h, wait for GAP - The ETPE is completely dissolved; pour the amino-functionalized graphene oxide dispersion into the GAP-ETPE solution, stir the system at 39°C for 1 hour, and pour it into the mold after being uniform. After standing at room temperature for 2 weeks, it was dried at 38° C. for 4.0 h to obtain 6.0 g of the corresponding amino-functionalized graphene oxide / polyazide glycidyl ether-based energetic thermoplastic elastomer (GAP-ETPE) composite. The stress of the amino-functionalized graphene oxide / GAP-ETPE composite is 7.48MPa, the strain is 12.26, the thermal decomposition temperature is 238.4℃, and the glass transition temperature is -30.0℃.

Embodiment 3

[0053] Add 55mg of 3-aminopropyltriethoxysilane modified graphene oxide into 125g of tetrahydrofuran, disperse ultrasonically at 33°C for 1.0h, add 5.9g of GAP-ETPE into 190g of tetrahydrofuran, stir at 33°C for 1.5h, wait for GAP -ETPE is completely dissolved; pour the amino-functionalized graphene oxide dispersion into the GAP-ETPE solution, stir the system at 36°C for 0.8h, and pour it into the mold after being uniform. After standing at room temperature for 1 week, bake at 37° C. for 3.5 h to obtain 5.9 g of the corresponding amino-functionalized graphene oxide / polyazide glycidyl ether-based energetic thermoplastic elastomer (GAP-ETPE) composite. The stress of the 3-aminopropyltriethoxysilane modified graphene oxide / polyazide glycidyl ether based energetic thermoplastic elastomer composite is 6.84MPa, the strain is 12.06, the thermal decomposition temperature is 239.7℃, and the glass transition temperature is -30.6°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal decomposition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| thermal decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com