Chip thin-film resistor network

A thin-film resistor and network technology, which is applied in the direction of thin-film resistors, other resistor networks, resistors, etc., can solve the problem that the temperature coefficient of the thin-film resistor network cannot meet the requirements of use, so as to eliminate vulcanization, reduce damage, and ensure stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

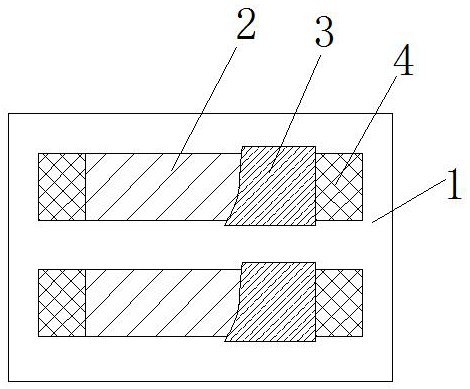

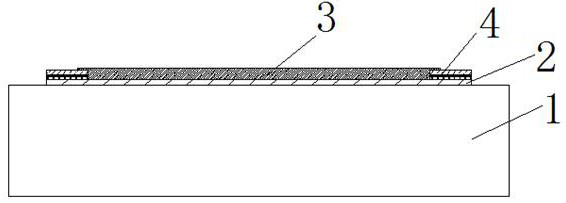

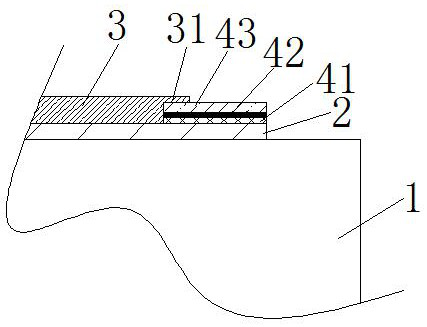

[0029] Such as Figure 1-3 As shown in , a chip-type thin-film resistor network includes a ceramic substrate 1, and a resistive film layer 2 is sputtered on the front of the ceramic substrate 1, and the resistive film layer 2 is a nickel-chromium alloy film, and the resistive film layer 2 is composed of Laser scribing and cutting into individual resistors (eg figure 1 In the figure are two individual resistors), each resistor individual surface is provided with two front electrodes 4 arranged in pairs and separated from each other, the front electrode 4 includes a barrier layer 41, an electrode bottom layer 42 and an electrode surface layer 43 from bottom to top, A passivation layer 3 is provided on the surface of the individual resistor located between the front electrodes 4;

[0030] The barrier layer 41 is a sputtered tungsten-titanium film layer, the electrode bottom layer 42 is a sputtered gold layer, and the electrode surface layer 43 is an electroplated gold layer; the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com