A silicon photocathode modified with tungsten sulfide nanoparticles and its preparation method

A nanoparticle and photocathode technology, applied in electrodes, nanotechnology, electrolytic components, etc., can solve the problems of uneven deposition thickness, low deposition rate, and high preparation cost, and achieve great application potential, low reagent cost, and tight interface bonding. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

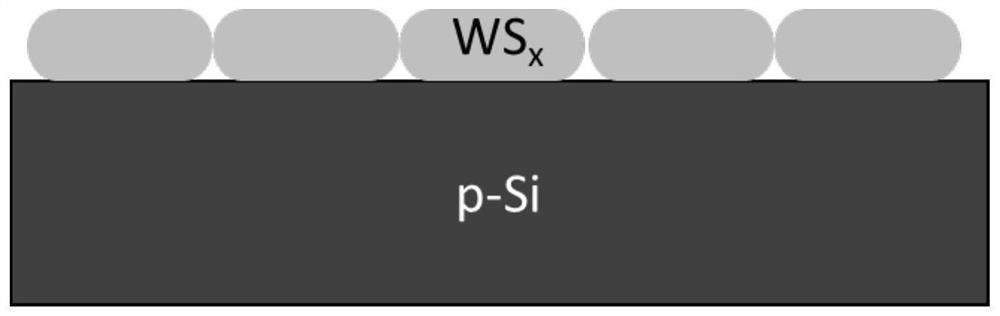

[0018] A silicon photocathode modified with tungsten sulfide nanoparticles and a preparation method thereof, comprising the following steps:

[0019] Cut the p-type single crystal silicon into a square sample with a side length of 1cm with a glass knife, place it in a mixed solution of 10mL concentrated sulfuric acid and 5mL hydrogen peroxide at 60 o C cleaning for 40 minutes, followed by etching with 2.0% hydrofluoric acid for 10 minutes to obtain bare silicon without an oxide layer; dissolving 2.0 mmol of ammonium thiotungstate in 10 mL of water to prepare a 0.2M ammonium thiotungstate solution, and then Take 0.05mL of the ammonium thiotungstate solution and drop it into 10mL of 5.0% hydrofluoric acid solution to prepare a 1.0mM ammonium thiotungstate mixed hydrofluoric acid solution, and place the above-mentioned p-type monocrystalline silicon without oxide layer on the In this solution for 5min, thereafter washed with a large amount of ultrapure water and dried with argon ...

Embodiment 2

[0021] A silicon photocathode modified with tungsten sulfide nanoparticles and a preparation method thereof, comprising the following steps:

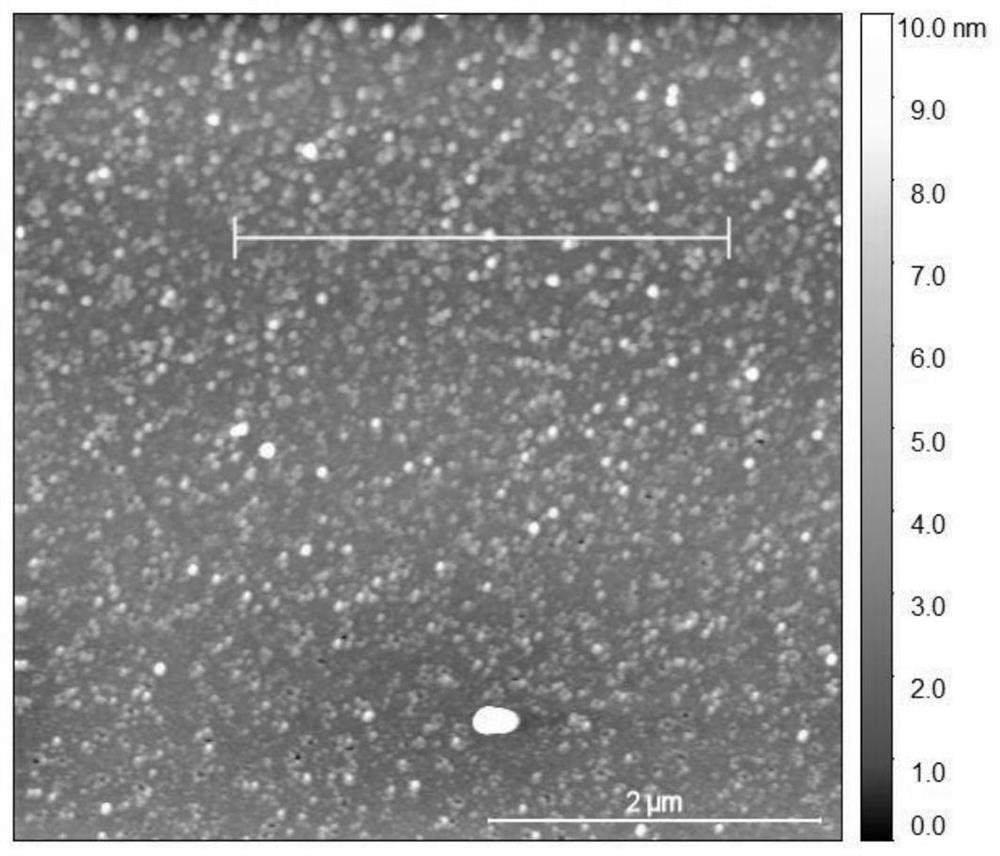

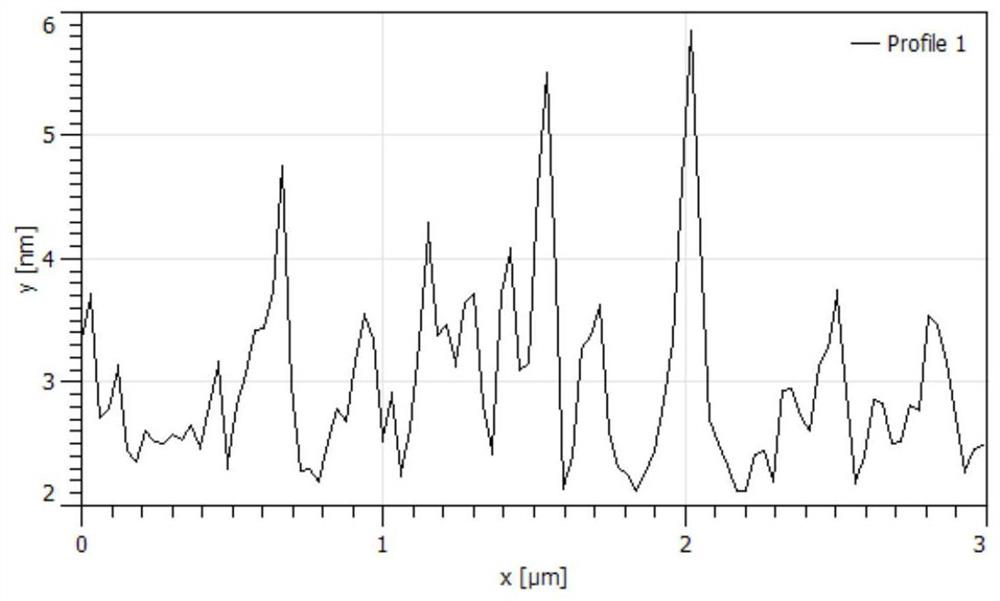

[0022] Cut the p-type single crystal silicon into a square sample with a side length of 1cm with a glass knife, place it in a mixed solution of 10mL concentrated sulfuric acid and 5mL hydrogen peroxide at 60 o C for 40 minutes, then etched with 5.0% hydrofluoric acid for 5 minutes to obtain bare silicon without an oxide layer; take 1.0 mmol of ammonium thiotungstate dissolved in 10 mL of water to prepare a 0.1M ammonium thiotungstate solution, and then Take 0.02mL of the ammonium thiotungstate solution and drop it into 10mL of 6.0% hydrofluoric acid solution to prepare a 0.2mM ammonium thiotungstate mixed hydrofluoric acid solution, and place the above-mentioned p-type single crystal silicon without oxide layer on the 20min in this solution, thereafter wash with a large amount of ultrapure water and dry with argon, make such as figure ...

Embodiment 3

[0024] A silicon photocathode modified with tungsten sulfide nanoparticles and a preparation method thereof, comprising the following steps:

[0025] Cut the p-type single crystal silicon into a square sample with a side length of 1cm with a glass knife, place it in a mixed solution of 10mL concentrated sulfuric acid and 5mL hydrogen peroxide at 60 o C for 40 minutes, followed by etching with 3.0% hydrofluoric acid for 5 minutes to obtain bare silicon without an oxide layer; take 1.0 mmol of ammonium thiotungstate dissolved in 10 mL of water to prepare a 0.1M ammonium thiotungstate solution, and then Take 0.01mL of the ammonium thiotungstate solution and drop it into 10mL of 8.0% hydrofluoric acid solution to prepare a 0.1mM ammonium thiotungstate mixed hydrofluoric acid solution, and place the above-mentioned p-type single crystal silicon without oxide layer on the 20min in this solution, thereafter wash with a large amount of ultrapure water and dry with argon, make such as ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com