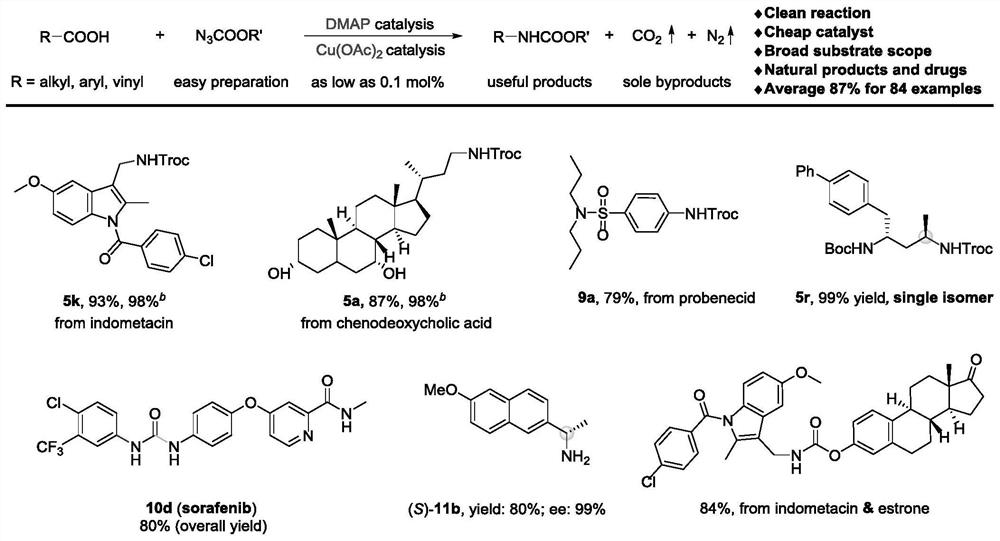

Method for preparing amine compounds based on novel catalytic Curtius rearrangement reaction

An amine compound, rearrangement reaction technology, applied in the preparation of organic compounds, the preparation of aminohydroxy compounds, steroid compounds, etc., can solve the problem of few C-N bonds, and achieve the effect of efficient synthesis and rapid construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

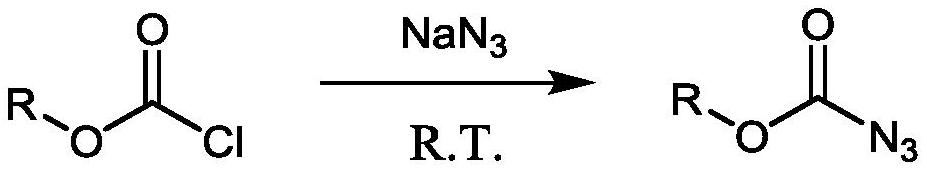

Method used

Image

Examples

Embodiment 1

[0052] Preparation of 2,2,2-trichloroethyl-((1-(4-chlorobenzoyl)-5-methoxy-2-methyl-1H-indole-3-)methyl)carbamate ester

[0053] The target product passes through the reaction process and post-processing. Purification by column chromatography afforded 94.0 mg of the target product (93% isolated yield).

[0054] 1 H NMR (400MHz, Chloroform-d) δ7.64(d, J=8.5Hz, 2H), 7.49(d, J=8.4Hz, 2H), 7.03(d, J=2.5Hz, 1H), 6.81(d ,J=9.0Hz,1H),6.66(dd,J=9.1,2.6Hz,1H),5.25(t,J=5.5Hz,1H),4.76(s,2H),4.53(d,J=5.5Hz ,2H),3.81(s,3H),2.42(s,3H); 13 C NMR (101MHz, Chloroform-d) δ168.4, 156.2, 154.7, 139.6, 136.5, 133.7, 131.3, 131.0, 129.9, 129.3, 115.6, 115.1, 112.1, 101.3, 95.7, 74.7, 55.8, 35.4, 13.2; )v 3344, 2929, 1732, 1682, 1591, 1478, 1221, 1045, 811, 721cm -1 ; HRMS (ESI) Calcd.for C21 h 18 Cl 4 N 2 o 4 Na[M+Na] + 524.9913,found 524.9908.

Embodiment 2

[0056] Preparation of 2,2,2-trichloroethyl((R)-3-((3R,7R,8R,9S,10S,13R,14S,17R)-3,7-dihydroxy-10,13-dimethyl Hexadecylhydro-1H-cyclopenta[a]phenanthrene-17-)butyl)carbamate

[0057]

[0058] The target product passes through the reaction process and post-processing. Purification by column chromatography afforded 93.2 mg of the target product (87% isolated yield).

[0059] 1 H NMR (400MHz, Chloroform-d) δ4.95(t, J=6.1Hz, 1H), 4.72(s, 2H), 3.84(q, J=3.0Hz, 1H), 3.49–3.42(m, 1H) ,3.34–3.26(m,1H),3.21–3.12(m,1H),2.19(q,J=12.7Hz,1H),2.00–1.94(m,2H),1.92–1.86(m,1H),1.84 –1.78(m,2H),1.72–1.59(m,4H),1.52–1.45(m,6H),1.41–1.33(m,3H),1.31–1.09(m,7H),0.97(d,J= 6.6Hz,4H),0.90(s,3H),0.65(s,3H); 13 C NMR (101MHz, Chloroform-d) δ154.6, 95.9, 74.6, 72.1, 68.6, 56.1, 50.6, 42.9, 41.6, 40.0, 39.7, 39.5, 39.0, 36.0, 35.4, 35.2, 34.8, 33.9, 32.9, 30.8 ,28.5,23.8,22.9,20.7,18.7,11.9; IR (neat) v3445,3347,2932,2867,2133,1715,1520,1251,1141,731cm -1 ; HRMS (ESI) Calcd.for C 26 h 42 Cl 3 ...

Embodiment 3

[0061] Preparation of 2,2,2-trichloroethyl(4-(N,N-dipropylsulfamoyl)phenyl)carbamate

[0062]

[0063] The target product passes through the reaction process and post-processing. Purification by column chromatography afforded 67.8 mg of the target product (79% isolated yield). 1 H NMR (400MHz, Chloroform-d) δ7.77 (d, J = 8.7Hz, 2H), 7.57 (d, J = 8.7Hz, 2H), 7.29 (brs, 1H), 4.84 (s, 2H), 3.08 –3.04(m,4H),1.59–1.50(m,4H),0.86(t,J=7.4Hz,6H); 13 C NMR (101MHz, Chloroform-d) δ151.4, 140.9, 135.3, 128.6, 118.6, 95.1, 74.8, 50.2, 22.1, 11.3; IR (neat) v3319, 2966, 1751, 1596, 1533, 1207, 1151, 590cm -1 ; HRMS (ESI) Calcd.for C 15 h 22 Cl 3 N 2 o 4 S[M+H] + 431.0361,found 431.0362.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com