High-performance sintered neodymium-iron-boron magnet and preparation method thereof

A NdFeB high-performance technology, applied in magnetic objects, inductance/transformer/magnet manufacturing, magnetic materials, etc., can solve the problems of limiting the magnet's anti-vibration, anti-vibration, poor anti-shock ability, and large difference in potential difference, etc. Corrosion resistance and toughness, excellent strength and flexibility, effect of increasing Curie temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

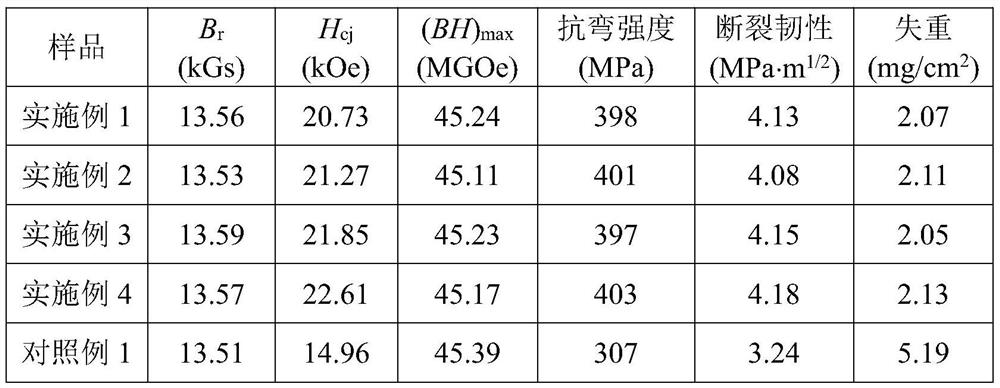

Examples

Embodiment 1

[0022] (1) The composition is Nd prepared by vacuum quick-setting process 29 Fe bal B 0.9 The main phase alloy A, the melting temperature is 1400°C, and the copper roll speed is 1m / s. The composition is Dy prepared by vacuum quick-setting process 40 Fe bal B 0.9 COL 0.01 The grain boundary phase alloy B, where L is a carbon nanotube, the diameter of the carbon nanotube is 1 nm, and the length is 1 μm. The melting temperature of the grain boundary phase alloy is 1300°C, and the rotational speed of the copper roll is 2m / s.

[0023] (2) The main phase alloy A and the grain boundary phase alloy B are respectively powdered by hydrogen crushing and jet milling, and the main phase alloy powder A1 with an average grain size of 2.0 μm and the grain boundary phase alloy powder of 0.5 μm are obtained B1.

[0024] (3) Fully mix the main phase alloy powder A1 and the grain boundary phase alloy powder B1 at a mass percentage ratio of 97.0:3.0 to obtain a mixed powder C.

[0025] (4...

Embodiment 2

[0027] (1) The composition is Nd prepared by vacuum quick-setting process 30 Fe bal B 1.0 The main phase alloy A, the melting temperature is 1430°C, and the copper roll speed is 1m / s. The composition is Dy prepared by vacuum quick-setting process 50 Fe bal B 1.0 Cu 2 L 0.5 The grain boundary phase alloy B, wherein L is a carbon nanotube, the diameter of the carbon nanotube is 10 nm, and the length is 10 μm. The melting temperature of the grain boundary phase alloy is 1320°C, and the rotational speed of the copper roll is 2m / s.

[0028] (2) The main phase alloy A and the grain boundary phase alloy B are respectively powdered by hydrogen crushing and jet milling, and the main phase alloy powder A1 with an average grain size of 3.0 μm and the grain boundary phase alloy powder of 1.0 μm are obtained B1.

[0029] (3) Fully mix the main phase alloy powder A1 and the grain boundary phase alloy powder B1 at a mass percentage of 99.9:0.1 to obtain a mixed powder C.

[0030] (...

Embodiment 3

[0032] (1) The composition is Nd prepared by vacuum quick-setting process 31 Fe bal B 1.0 The main phase alloy A, the melting temperature is 1450°C, and the copper roll speed is 1m / s. The composition is Tb prepared by vacuum quick-setting process 60 Fe bal B 1.0 Al 3 L 0.7 The grain boundary phase alloy B, wherein L is a carbon nanotube, the diameter of the carbon nanotube is 30nm, and the length is 15μm. The melting temperature of the grain boundary phase alloy is 1340°C, and the rotational speed of the copper roll is 2m / s.

[0033] (2) The main phase alloy A and the grain boundary phase alloy B are respectively powdered by hydrogen crushing and jet milling, and the main phase alloy powder A1 with an average grain size of 4.0 μm and the grain boundary phase alloy powder of 1.5 μm are obtained B1.

[0034](3) Fully mix the main phase alloy powder A1 and the grain boundary phase alloy powder B1 at a mass percentage of 98.5:1.5 to obtain a mixed powder C.

[0035] (4) ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| magnetic flux density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com