A kind of processing technology of Verseat

A processing technology, the technology of the valve seat, applied in the direction of metal processing equipment, metal processing machinery parts, manufacturing tools, etc., can solve the problems of large machining allowance, high grinding heat, loose material structure, etc., and achieve workpiece dimensional accuracy and High degree of position, improve the mechanical properties of the material, and improve the effect of the structure of the material

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

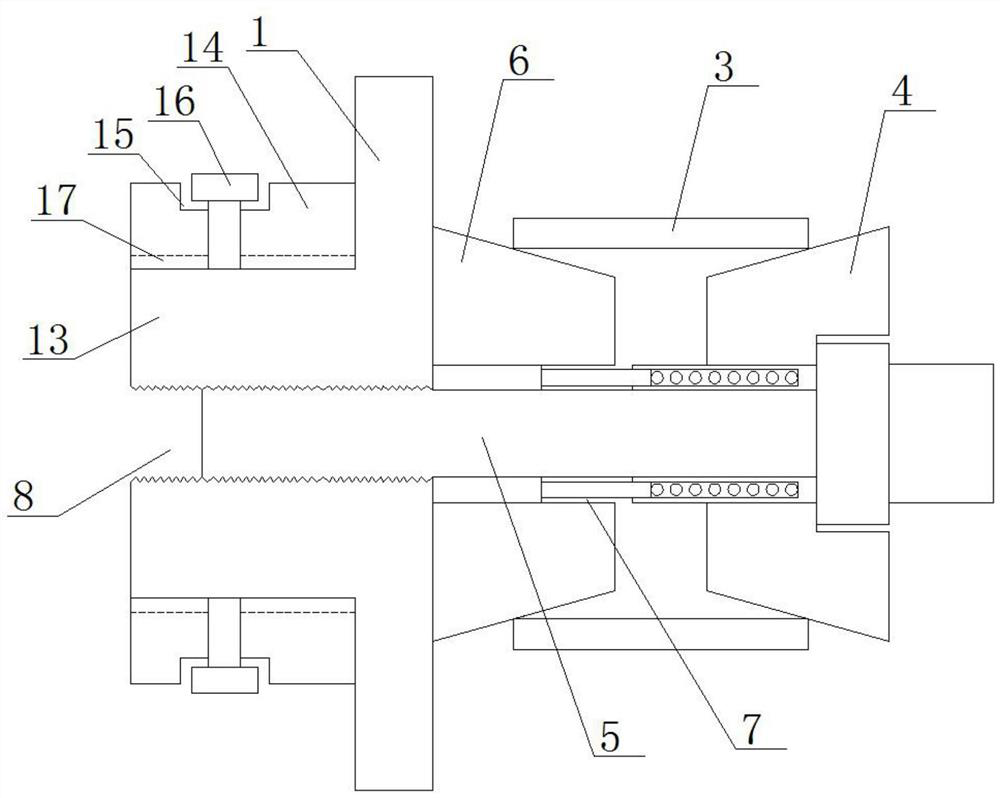

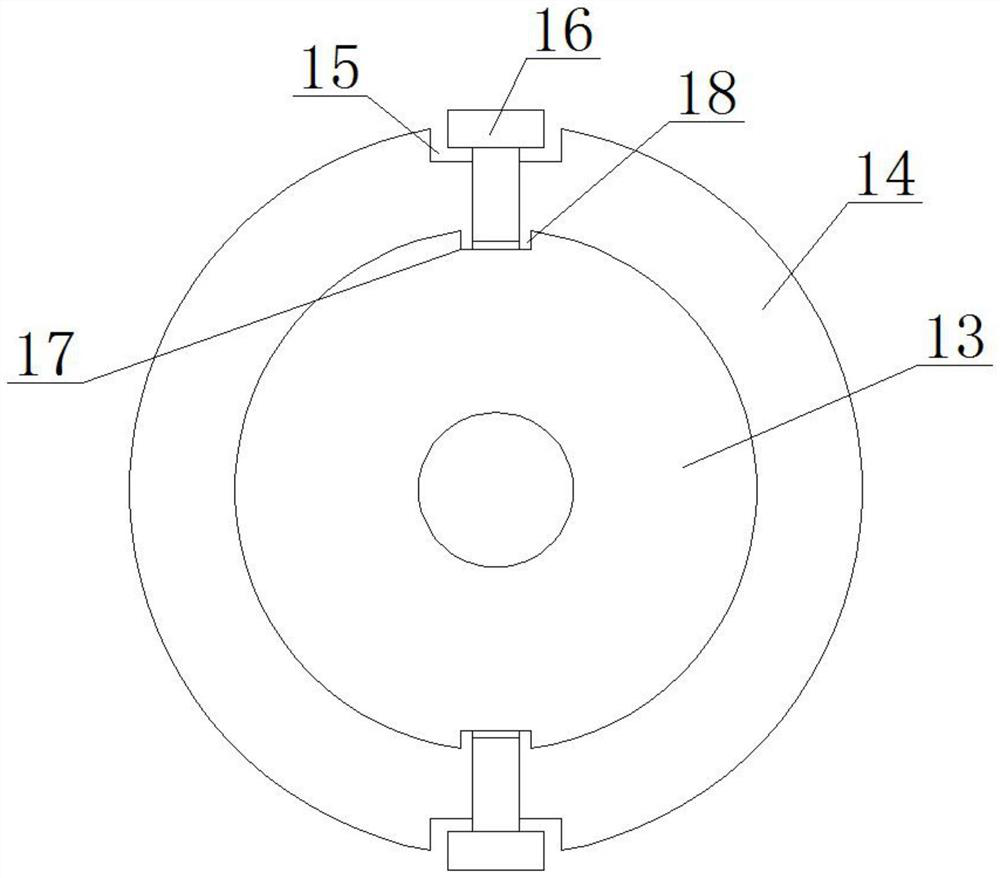

[0041] As a preferred embodiment of the present invention, the diameter of the guide tube 10 is the same as that of the guide hole 7 .

[0042] As a preferred embodiment of the present invention, a guide hole 7 is provided at the center of the left round pedestal 6, and a retractable guide tube 10 is installed on one side of the locking round pedestal 4, so that the clip can be clamped when in use. The axes of the holding body 1 and the locking round pedestal 4 are on the same straight line, and the centering effect is good. The spring 2 is installed in the annular telescopic groove 9, and one end of the inner pipe 11 at one end of the guide pipe 10 is in the annular telescopic groove 9 and It is fixedly connected with the spring 2, so the guide tube 10 has a certain flexibility. When the locking bolt 5 is loosened, the guide tube 10 pushes the locking round pedestal 4 away, and the expansion pressure of the elastic sleeve 3 is released and quickly tightened inward, which can e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com