A new type of composite gypsum block and its application

A technology of gypsum blocks and gypsum blocks, which is applied in the field of building materials, can solve problems such as poor corrosion resistance, and achieve the effects of preventing water vapor corrosion, good barrier effect, and reducing erosion speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

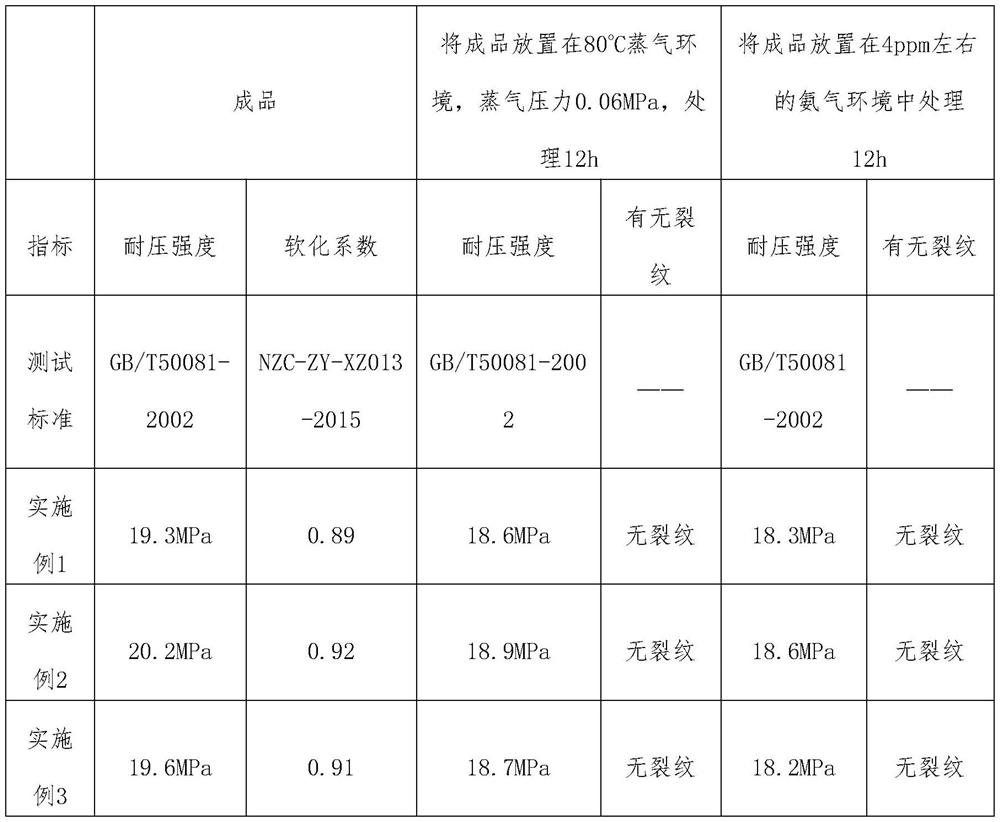

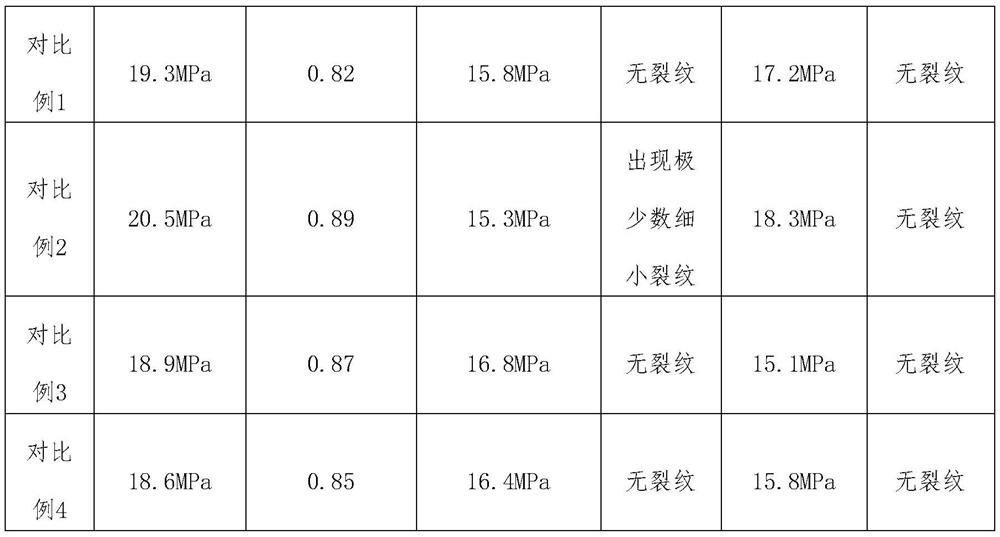

Examples

Embodiment 1

[0028] The gypsum block is made of the following raw materials: 30 parts of hemihydrate gypsum, 6 parts of slag, 3 parts of expanded perlite, 4 parts of silicon powder, 0.5 part of nanofiber, 3 parts of solid phase change heat storage material, 0.1 part of sodium silicate, 0.1 part of polycarboxylate superplasticizer.

[0029] Among them, hemihydrate gypsum is made by sintering phosphogypsum.

[0030] The preparation of solid phase change heat storage materials is as follows: mix polyvinyl alcohol and polyethylene glycol with a mass ratio of 5:1 to form a mixture, add water 20 times the weight of the mixture, heat to 70-80°C, and then add Activated carbon powder with a mass of 10% of the mixture is heat-preserved and stirred for 6-7 hours, left standing for 4-5 hours, concentrated by evaporation, dried, and pelletized to obtain a solid phase-change heat storage material.

[0031] The steam-proof block is made of the following raw materials: 6 parts of ethylene-vinyl acetate c...

Embodiment 2

[0040] The gypsum block is made of the following raw materials: 34 parts of hemihydrate gypsum, 7 parts of slag, 4 parts of expanded perlite, 5 parts of silicon powder, 0.8 part of nanofiber, 3.5 parts of solid phase change heat storage material, 0.12 part of sodium silicate, 0.12 parts of polycarboxylate superplasticizer.

[0041] Among them, hemihydrate gypsum is made by sintering desulfurized gypsum.

[0042] The preparation of solid phase change heat storage materials is as follows: mix polyvinyl alcohol and polyethylene glycol with a mass ratio of 5:1 to form a mixture, add water 20 times the weight of the mixture, heat to 70-80°C, and then add Activated carbon powder with a mass of 13% of the mixture is heat-preserved and stirred for 6-7 hours, left to stand for 4-5 hours, concentrated by evaporation, dried, and pelletized to obtain a solid phase-change heat storage material.

[0043] The steam-proof block is made of the following raw materials: 5.4 parts of ethylene-vi...

Embodiment 3

[0052] The gypsum block is made of the following raw materials: 40 parts of hemihydrate gypsum, 8 parts of slag, 5 parts of expanded perlite, 6 parts of silicon powder, 1 part of nanofiber, 4 parts of solid phase change heat storage material, 0.2 part of sodium silicate, 0.15 parts of polycarboxylate superplasticizer.

[0053] Among them, hemihydrate gypsum is made by sintering citrate gypsum.

[0054] The preparation of solid phase change heat storage materials is as follows: mix polyvinyl alcohol and polyethylene glycol with a mass ratio of 5:1 to form a mixture, add water 20 times the weight of the mixture, heat to 70-80°C, and then add Activated carbon powder with a mass of 15% of the mixture is heat-preserved and stirred for 6-7 hours, left standing for 4-5 hours, concentrated by evaporation, dried, and pelletized to obtain a solid phase-change heat storage material.

[0055] The steam-proof block is made of the following raw materials: 6 parts of ethylene-vinyl acetate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com