Inert gas purification catalyst, raw material composition and preparation method

A raw material composition, inert gas technology, applied in the directions of inert gas compounds, physical/chemical process catalysts, nitrogen compounds, etc., can solve the problems of non-renewable, high cost, unfavorable industrial use, etc., to achieve increased adsorption, low production cost, Remove the deep effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

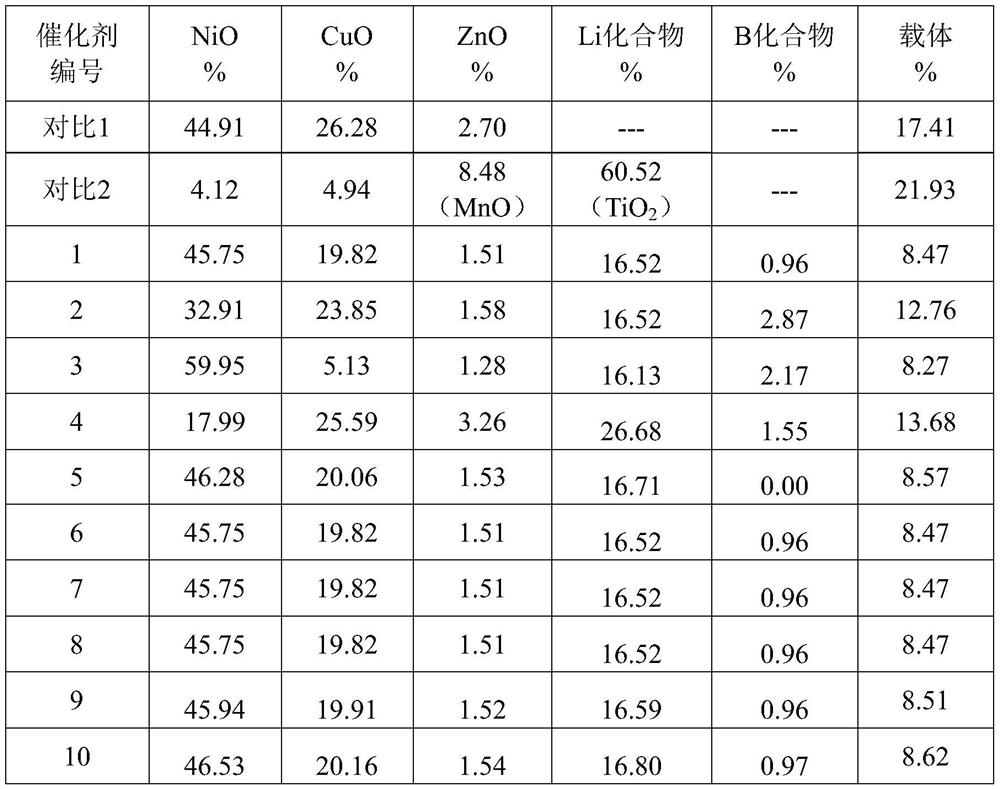

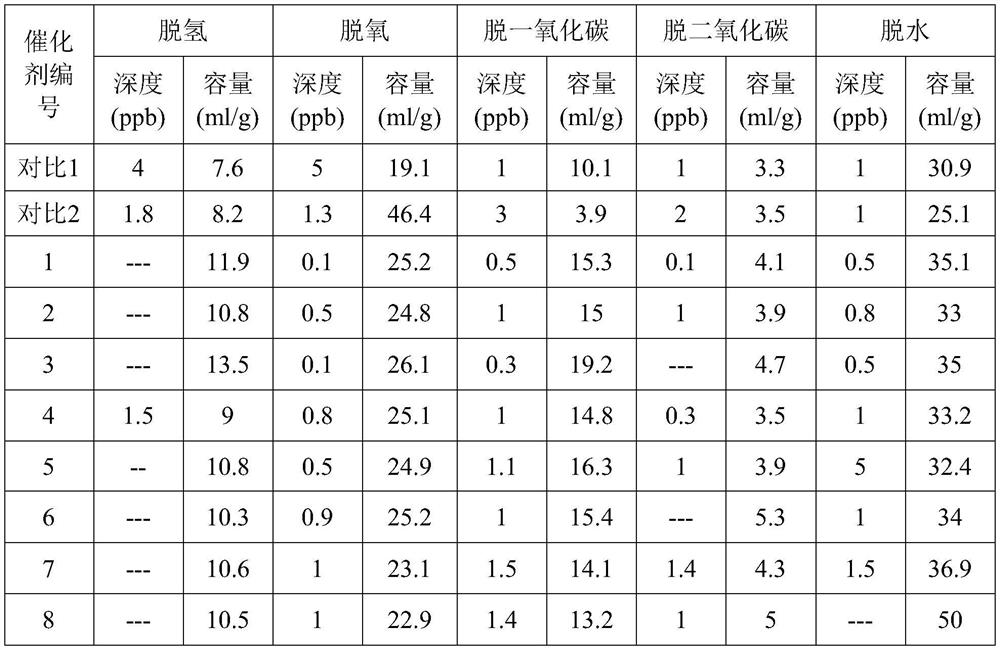

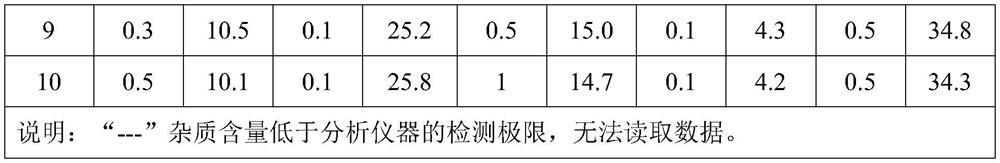

Embodiment 1

[0035] (1) After getting 47g of lithium sulfate and 4.3g of borax to be ground by a ball mill, they were added to 300ml of ethanol solution and subjected to ultrasonic treatment for 2 hours. (2) Weigh 180g of basic nickel carbonate, 65g of basic copper carbonate and 7.5g of basic zinc carbonate, mix them after ball mill grinding, and add the mixture into the ethanol mixture containing lithium sulfate and borax. Stir at room temperature (25° C.) for 6 hours, collect the solids by filtration, and dry the catalyst active component and auxiliary agent mixture. (3) Weigh 20 g of Beta molecular sieve and fully mix with the dried catalyst active component and auxiliary agent mixture, and finally use aluminum sol with an aluminum content of 5% as a binder for molding. (4) After forming, the catalyst was dried naturally in an oven at 110° C. overnight, then transferred to a muffle furnace with nitrogen protection gas, and roasted at 350° C. for 6 hours to obtain catalyst No. 1.

Embodiment 2

[0037] (1) Get 31g of lithium sulfate and 8.6g of borax after being ground by a ball mill, add them into 300ml of ethanol solution, and process them with ultrasonic waves for 2 hours. (2) Weigh 86g of basic nickel carbonate, 52g of basic copper carbonate and 5.2g of basic zinc carbonate, grind them in a ball mill, mix them, and add the mixture to the ethanol mixture containing lithium sulfate and borax. Stir at room temperature (25° C.) for 6 hours, collect the solids by filtration, and dry the catalyst active component and auxiliary agent mixture. (3) Weigh 20 g of Beta molecular sieve and fully mix with the dried catalyst active component and auxiliary agent mixture, and finally use aluminum sol with an aluminum content of 5% as a binder for molding. (4) The molded catalyst was dried naturally in an oven at 110°C overnight, then transferred to a muffle furnace with nitrogen protection gas, and roasted at 350°C for 6 hours to obtain catalyst No. 2.

Embodiment 3

[0039] (1) Get 47g of lithium sulfate and 10g of borax after being ground by a ball mill, add them into 300ml of ethanol solution, and process them with ultrasonic waves for 2 hours. (2) Weigh 242g of basic nickel carbonate, 17g of basic copper carbonate and 6.5g of basic zinc carbonate, mix them after being ground by a ball mill, and add the mixture to the ethanol mixture containing lithium sulfate and borax. Stir at room temperature (25° C.) for 6 hours, collect the solids by filtration, and dry the catalyst active component and auxiliary agent mixture. (3) Weigh 20 g of Beta molecular sieve and fully mix with the dried catalyst active component and auxiliary agent mixture, and finally use aluminum sol with an aluminum content of 5% as a binder for molding. (4) The molded catalyst was dried naturally in an oven at 110° C. overnight, then transferred to a muffle furnace with nitrogen protective gas, and calcined at 350° C. for 6 hours to obtain catalyst No. 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com