Zinc-containing artificial bone and preparation method thereof

A technology of artificial bone and technology, applied in the medical field, can solve the problems of difficult bone repair in load-bearing parts, poor osteoinductivity of artificial bone, poor mechanical strength of artificial bone, etc., achieve good bone-promoting performance, solve poor osteoinductivity, good reliability The effect of biodegradation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

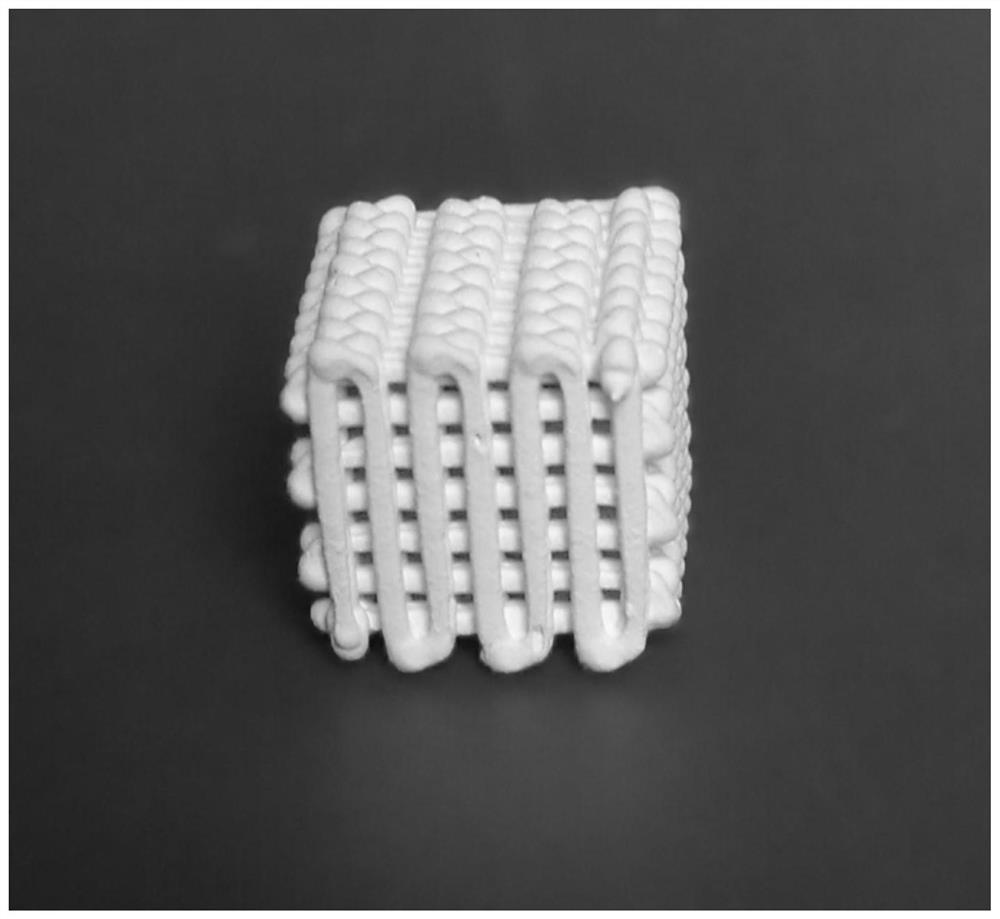

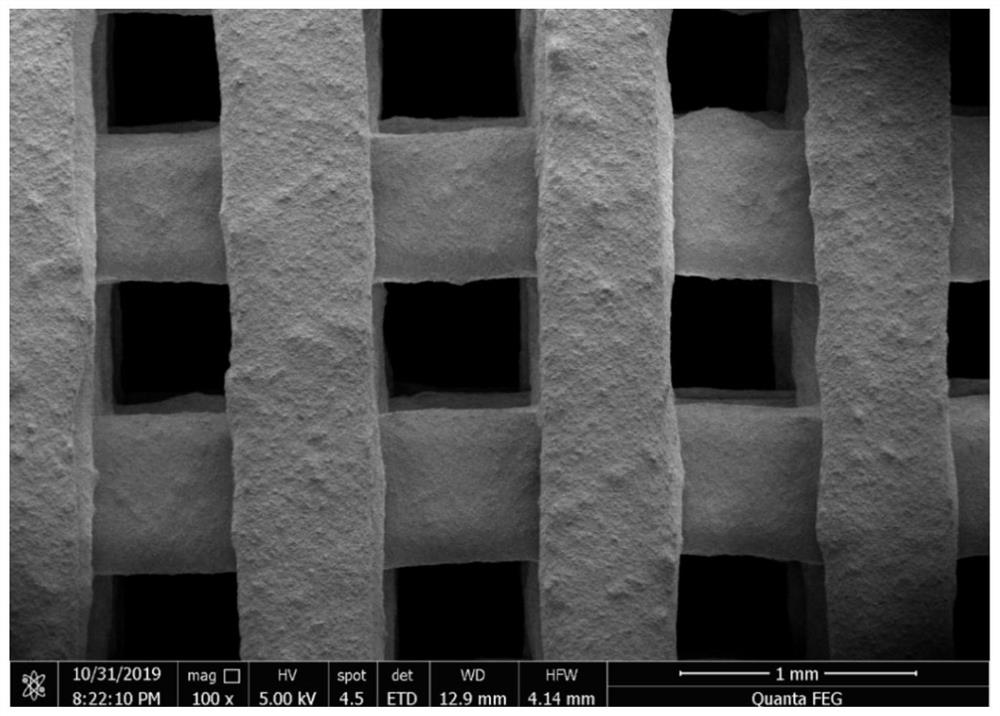

[0048] The invention provides a preparation method of the zinc-containing artificial bone, which is prepared through a process of additive manufacturing (3D printing). The preparation method of the additive manufacturing (3D printing) may be a wireless extrusion 3D printing process, a powder coating 3D printing process or a photocuring 3D printing process. All of them can prepare the zinc-containing artificial bone described in this patent through proper selection of binder and adjustment of process method.

[0049] The preparation method of the wireless extrusion 3D printing zinc-containing artificial bone is as follows:

[0050] (1) Paste preparation: weigh the bioceramic powder and the zinc-containing powder in proportion and mix them evenly to obtain a solid material, and dilute the high molecular polymer binder into an aqueous solution of a certain concentration to obtain a liquid material. The solid material and the liquid material are mixed and stirred evenly, and then...

Embodiment 1

[0072] Embodiment 1 contains the preparation of pure zinc artificial bone (wireless extrusion)

[0073] (1) The bioceramic material is selected as a mixed powder of β-tricalcium phosphate (β-TCP) and hydroxyapatite (HA), and the mixing ratio of the two is 3.5:1. Powder particle size 10μm-20μm. The zinc-containing component is selected as pure zinc powder, the purity of which is higher than 99%, and the particle size of the pure zinc powder is 10 μm-20 μm. Select polyvinyl alcohol (PVA) as the polymer binder;

[0074] (2) Ingredients: According to the mass ratio, 10% of pure zinc powder, 84.5% of bioceramic powder (mixed with β-TCP and HA), and 5.5% of polyvinyl alcohol are used as ingredients. Concrete steps Prepare 8g of polyvinyl alcohol and 92g of pure water to make a polyvinyl alcohol aqueous solution with a mass fraction of 8%, place it in a jar with a lid, heat and swell in a water bath at 60°C for 2h, and then place it in a magnetic stirrer at 96°C Stir at 250r / min f...

Embodiment 2

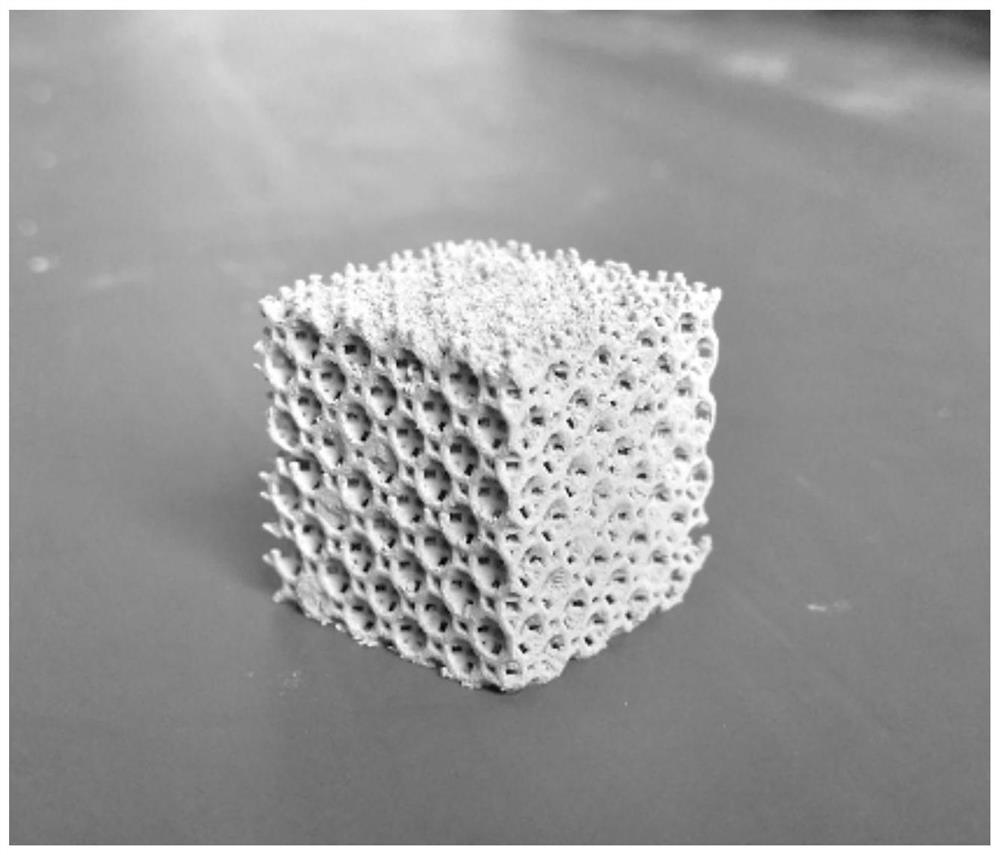

[0082] The preparation of embodiment 2 zinc-magnesium alloy artificial bone (spread powder and spray binder)

[0083] (1) In this embodiment, the bioceramic material is a mixture of calcium magnesium silicate and calcium sulfate, the mixing ratio of the two is 1:1, and the particle size of the powder is 10 μm. The zinc-magnesium binary alloy powder is selected as the zinc-containing component; the magnesium content in the zinc-magnesium alloy is 5% of the total mass fraction of the zinc-magnesium alloy, and the rest is zinc. The particle size of the zinc-magnesium alloy powder is 10 μm. Select phosphoric acid as binder;

[0084] (2) Batching: According to the mass ratio, 15% of zinc-magnesium alloy powder, 84.5% of the mixture of calcium magnesium silicate and calcium sulfate, and 0.5% of phosphoric acid are used for batching. Use a balance to weigh 150 grams of zinc-magnesium alloy powder in the above ratio, 845 grams of mixed powder of calcium magnesium silicate and calciu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Large hole diameter | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com