Neodymium-iron-boron permanent magnet and preparation method and application thereof

A technology of permanent magnets and NdFeB, which is applied in the fields of magnetic objects, inductors/transformers/magnets, magnetic materials, etc., and can solve the problems of unclear organizational structure, formula and performance correspondence, and little practical application significance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

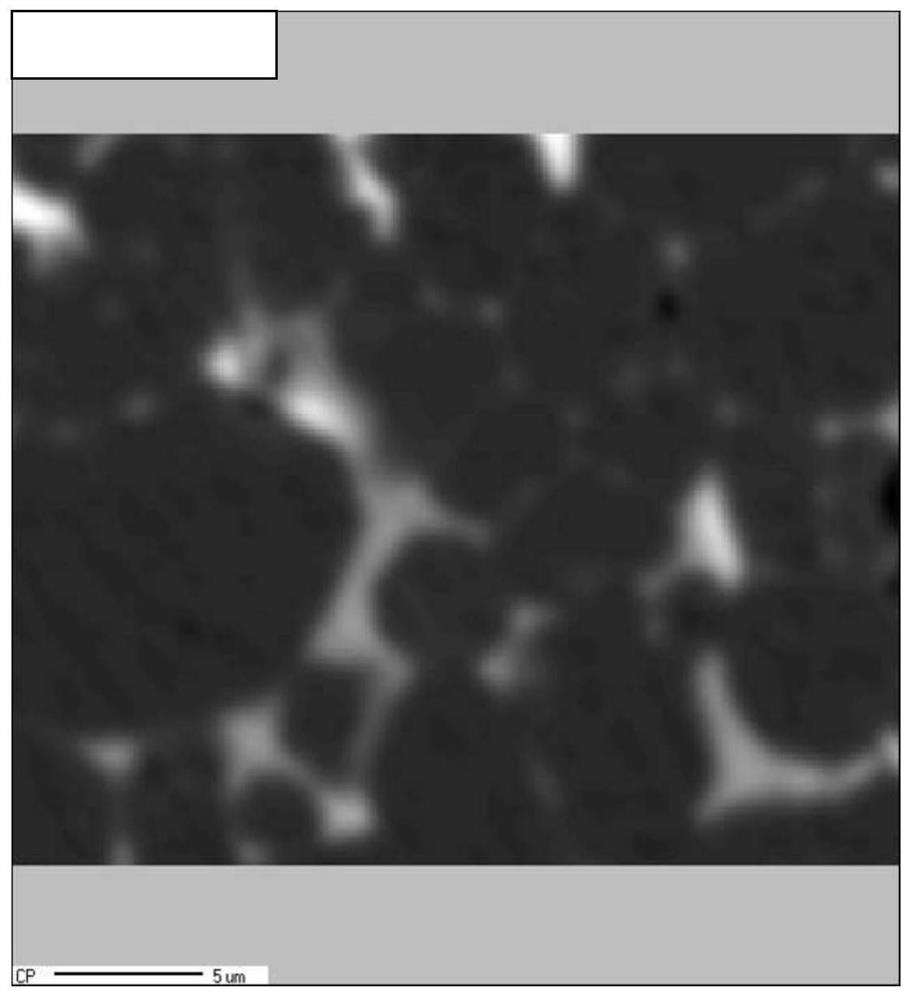

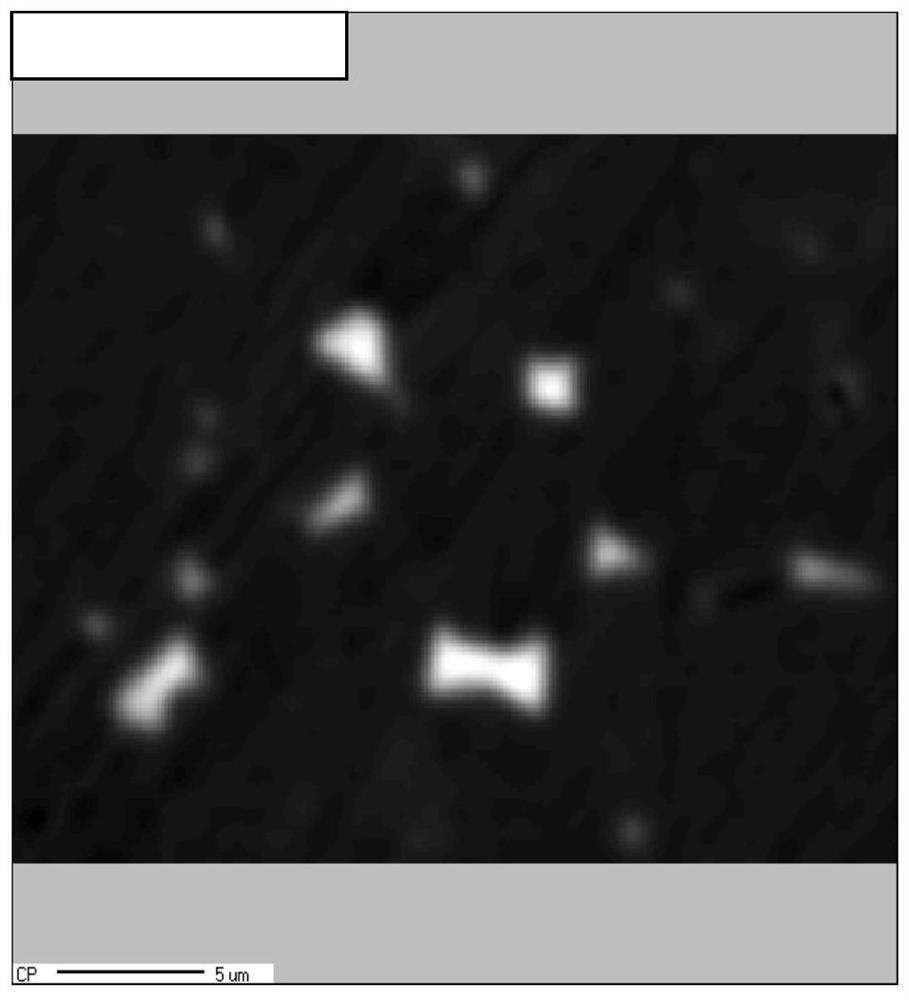

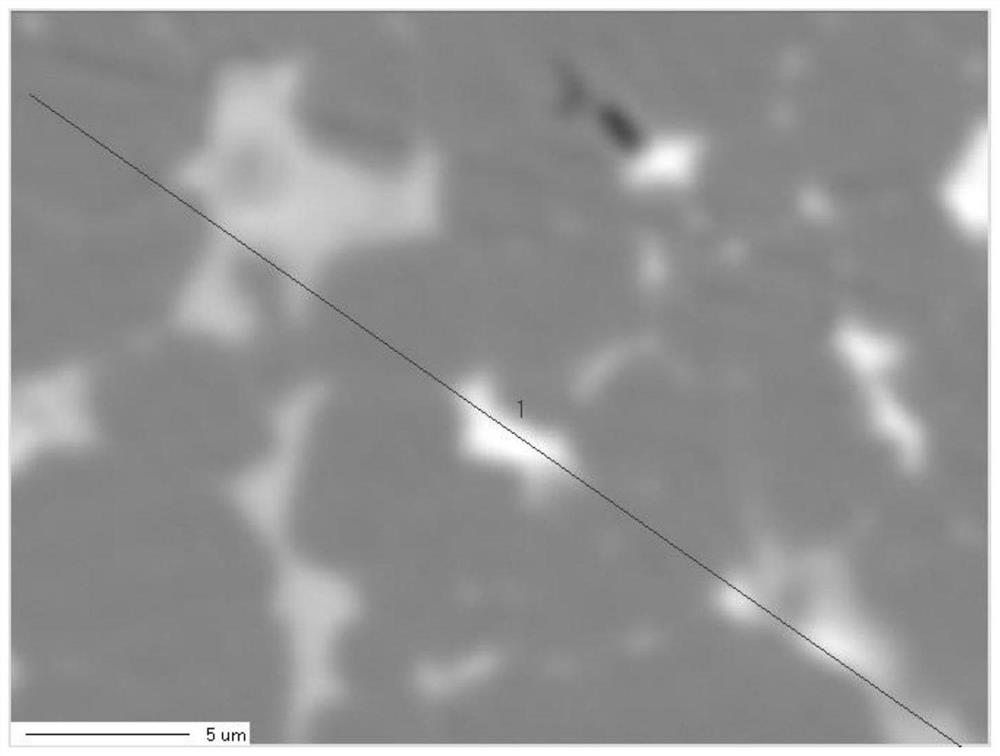

Image

Examples

Embodiment 1

[0106] (1) Ingredients: Prepare various raw materials required in this embodiment, the atomic percentage of the raw materials is 11.1% Nd, 2.9% Pr, 0.2% Dy, 2.24% Co, 0.37% Al, 0.16% Cu, 0.19% Ga, 0.12 Zr%, 5.55% B, and the rest are iron and unavoidable impurities. The formulation composition is shown in Table 1.

[0107] (2) The raw material is high-frequency melted in an Ar atmosphere, and poured onto a quenching roll to make an alloy quick-setting sheet with a thickness of 0.15-0.40mm.

[0108] (3) The alloy is hydrogenated and pulverized, and then jet milled to obtain a magnetic powder with a particle size of SMD=2.8 μm, X10=1.28 μm, and X100=18 μm.

[0109] (4) Add the above-mentioned jet mill powder to 0.2wt% of the lubricant as the raw material, then mix the mixture, and shape it in an orientation field environment with a magnetic field strength of 2T.

[0110] (5) Put the green body into the vacuum sintering furnace, after heat preservation at 1070°C for 4 hours, coo...

Embodiment 2

[0126] (1) Batching: prepare various raw materials needed in this embodiment, and the atomic percentage composition of the batching is shown in Table 3.

[0127] (2) The raw material is high-frequency melted in an Ar atmosphere, and poured onto a quenching roll to make an alloy quick-setting sheet with a thickness of 0.15-0.40mm.

[0128] (3) The alloy is hydrogenated and pulverized, and then jet milled to obtain a magnetic powder with a particle size of SMD=2.7 μm, X10=1.23 μm, and X100=15 μm.

[0129] (4) Add the above-mentioned jet mill powder to 0.3wt% of the lubricant as the raw material, mix the mixture, and shape it in an orientation field environment with a magnetic field strength of 2T.

[0130] (5) Put the green body into a vacuum sintering furnace, after heat preservation at 1075°C for 4 hours, cool to room temperature at a rate of 10°C / min, heat up to 800°C for 3 hours, and then proceed at a speed of 6°C / min Cool to room temperature, then heat up to 580°C for 4 ho...

Embodiment 3

[0143] (1) Ingredients: prepare various raw materials required for this embodiment, and the formula composition is shown in Table 5.

[0144] (2) The raw material is high-frequency melted in an Ar atmosphere, and poured onto a quenching roll to make an alloy quick-setting sheet with a thickness of 0.15-0.40 mm.

[0145] (3) The alloy is hydrogenated and pulverized, and then jet milled to obtain a magnetic powder with a particle size of SMD=2.9 μm, X10=1.28 μm, and X100=18 μm.

[0146] (4) Add the above-mentioned jet mill powder to 0.3wt% of the lubricant as the raw material, mix the mixture, and shape it in an orientation field environment with a magnetic field strength of 2T.

[0147] (5) Put the green body into a vacuum sintering furnace, after heat preservation at 1060°C for 4 hours, cool to room temperature at a rate of 10°C / min, heat up to 800°C for 3 hours, and then proceed at a speed of 6°C / min Cool to room temperature, then heat up to 560°C for 4 hours, then cool to r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com