Preparation method of anti-corrosion combustion-supporting wire or cable

A wire and cable, anti-corrosion technology, applied in the field of wire and cable, can solve the problems of secondary disasters, a large amount of smoke and hydrogen halide gas, and achieve the effect of reducing the amount of consumption, overcoming the short scorch time, and improving the vulcanization speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

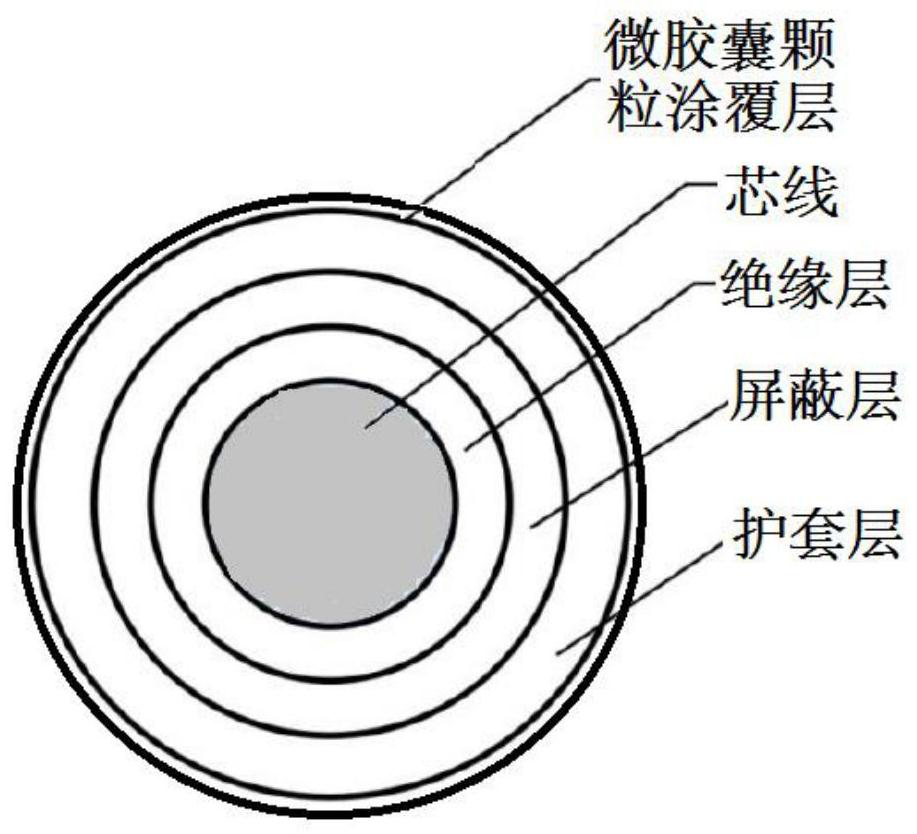

[0030] A method for preparing anti-corrosion and combustion-supporting wires and cables. Firstly, a plurality of wires are twisted into a bundle, and the insulation layer and the shielding layer are wrapped in turn on the outside to obtain a wire core. The outside of the core is wrapped with a sheath layer, and finally a coating layer of microcapsule particles is coated on the protective sheath to obtain the cable, wherein the sheath layer is prepared by the following method:

[0031] (1) 100kg polyvinyl chloride, 30kg stabilizer, 15kg plasticizer, 5kg lubricant, 5kg filler are utilized to mix with a plow mixer to obtain the mixture; the filler is mixed with calcium carbonate, phosphoric acid, asbestos, A mixture of aluminum hydroxide and diatomaceous earth is coated with magnesium hydroxide, and then the resulting product is mixed with ethyl naphthol, hexacyclite powder, and silicon carbide fibers, and then pentaerythritol triallyl ether, 3-aminopropyltrimethoxy Modified by b...

Embodiment 2

[0042] A method for preparing anti-corrosion and combustion-supporting wires and cables. Firstly, a plurality of wires are twisted into a bundle, and the insulation layer and the shielding layer are wrapped in turn on the outside to obtain a wire core. The outside of the core is wrapped with a sheath layer, and finally a coating layer of microcapsule particles is coated on the protective sheath to obtain the cable, wherein the sheath layer is prepared by the following method:

[0043] (1) 100kg polyvinyl chloride, 40kg stabilizer, 20kg plasticizer, 8kg lubricant, 8kg filler are utilized to mix with a plow mixer to obtain mixture; A mixture of aluminum hydroxide and diatomaceous earth is coated with magnesium hydroxide, and then the resulting product is mixed with ethyl naphthol, hexacyclite powder, and silicon carbide fibers, and then pentaerythritol triallyl ether, 3-aminopropyltrimethoxy Modified by base silane;

[0044] (2) The mixture is then placed in the internal mixer an...

Embodiment 3

[0054] A method for preparing anti-corrosion and combustion-supporting wires and cables. Firstly, a plurality of wires are twisted into a bundle, and the insulation layer and the shielding layer are wrapped in turn on the outside to obtain a wire core. The outside of the core is wrapped with a sheath layer, and finally a coating layer of microcapsule particles is coated on the protective sheath to obtain the cable, wherein the sheath layer is prepared by the following method:

[0055] (1) 100kg polyvinyl chloride, 30kg stabilizing agent, 20kg plasticizer, 5kg lubricant, 5kg filler are utilized to mix with a plow mixer to obtain mixture; A mixture of aluminum hydroxide and diatomaceous earth is coated with magnesium hydroxide, and then the resulting product is mixed with ethyl naphthol, hexacyclite powder, and silicon carbide fibers, and then pentaerythritol triallyl ether, 3-aminopropyltrimethoxy Modified by base silane;

[0056] (2) Then put the mixture in the internal mixer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com