Epoxy resin adhesive for bonding rubber materials and preparation method thereof

A technology of epoxy resin and rubber materials, applied in the direction of adhesives, non-polymer adhesive additives, adhesive additives, etc., can solve the problems of weather resistance and environmental resistance, difficult to control room temperature curing, insufficient toughness of adhesives, etc. problems, to achieve the effect of a wide range of working environments, intense molecular motion, and strong adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

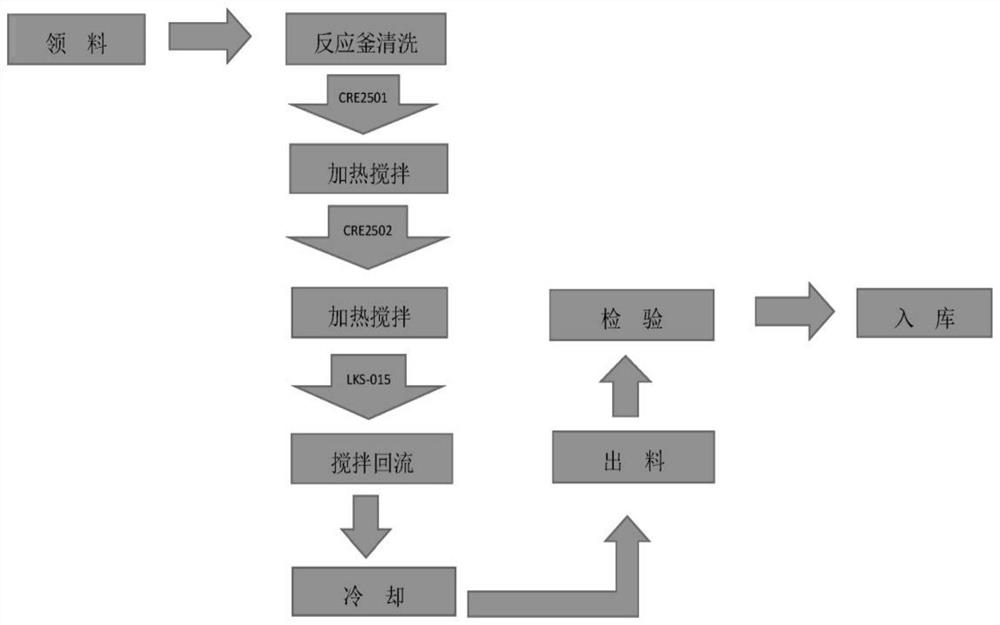

Embodiment 1

[0066] A kind of epoxy resin adhesive for rubber material bonding, comprises A component, B component and hydrophilic silica, the mass ratio of described A component, B component and hydrophilic silica is 100: 40-55:5-7, the A component is a polysiloxane modified epoxy resin body, and the B component is a low molecular weight polyamide curing agent.

[0067] The A component includes 86.2 parts by mass of linear organosilicon-modified epoxy and 13.8 parts by mass of hyperbranched epoxy to prepare a reaction stock solution, and 0.5 parts by mass of silane coupling agent is added to the reaction stock solution The reaction produces A component.

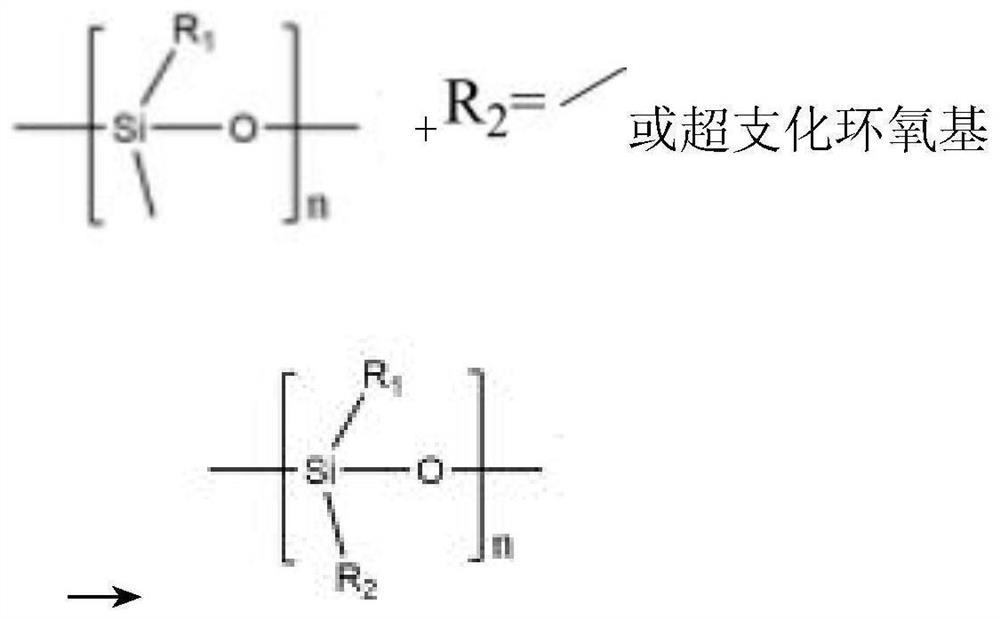

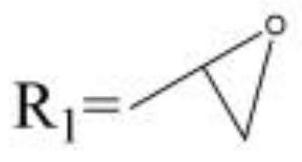

[0068] Such as figure 2 , Figure 2a-2e As shown, the molecular structural formula of the A component is prepared from a linear silicone modified epoxy resin CRE-2501 and a hyperbranched epoxy resin CRE-2502 through the coupling condensation of a silane coupling agent into a bead chain hyperbranched polymer structural formula :

[0...

Embodiment 2

[0091] A kind of epoxy resin adhesive for rubber material bonding, comprises A component, B component and hydrophilic silica, the mass ratio of described A component, B component and hydrophilic silica is 100: 40-55:5-7, the A component is a polysiloxane modified epoxy resin body, and the B component is a low molecular weight polyamide curing agent.

[0092] The mass ratio of A component, B component and hydrophilic silica described in this embodiment is 100:45:7, and the epoxy resin adhesive for rubber material bonding described in the present invention is prepared by mixing, and prepared as After the adhesive is discharged.

[0093] The A component includes 82 parts by mass of linear organosilicon-modified epoxy and 18 parts by mass of hyperbranched epoxy to obtain a reaction stock solution, and 2 parts by mass of silane coupling agent are added to the reaction stock solution The reaction produces A component.

[0094] Such as figure 2 , Figure 2a-2f As shown, the mole...

Embodiment 3

[0127] A kind of epoxy resin adhesive for rubber material bonding, comprises A component, B component and hydrophilic silica, the mass ratio of described A component, B component and hydrophilic silica is 100: 40-55:5-7, the A component is a polysiloxane modified epoxy resin body, and the B component is a low molecular weight polyamide curing agent.

[0128] The mass ratio of A component, B component and hydrophilic silica described in this example is 100:53:5, and the epoxy resin adhesive for rubber material bonding described in the present invention is prepared by mixing, and prepared as After the adhesive is discharged.

[0129] The A component includes 90 parts by mass of linear silicone-modified epoxy and 10 parts by mass of hyperbranched epoxy to prepare a reaction stock solution, and 1 part by mass of silane coupling agent is added to the reaction stock solution The reaction produces A component.

[0130] Such as figure 2 , Figures 2a-2g As shown, the molecular stru...

PUM

| Property | Measurement | Unit |

|---|---|---|

| peel strength | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| epoxy value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com