A kind of preparation method of continuous carbon fiber reinforced metal matrix composite material

A composite material and continuous fiber technology, which is applied in the field of continuous carbon fiber reinforced metal matrix composite materials, can solve the problems of carbon fiber agglomeration, achieve huge market potential, avoid entanglement, and broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

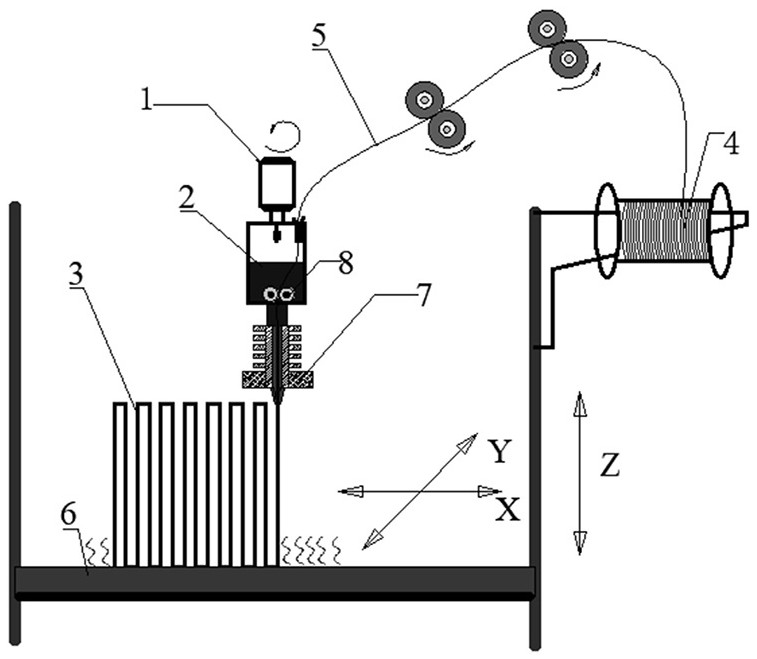

[0045] as attached Figure 1-19 Shown, the present invention is a kind of preparation method of continuous carbon fiber reinforced metal matrix composite material, comprises the following steps:

[0046] Step 1. Copper-plate the surface of the continuous carbon fiber after degumming, cleaning, neutralization, sensitization, and activation, so that the copper coating is evenly, densely and completely coated on the surface of the carbon fiber, and the thickness of the coating is 0.1~10μm continuous copper-coated carbon fibers;

[0047] Step 2. Use 3D printing equipment to coat the continuous carbon fiber filament with colloid, print the copper-plated continuous carbon fiber on the hot bed, and heat it to become a continuous copper-plated carbon fiber skeleton with a certain hardness, so that it can be in space Directional permutation distribution.

[0048] Step 3. According to the actual needs, put powders of different ingredients and ratios into the mixer for a period of mixi...

Embodiment 1

[0074] A method for preparing continuous carbon fiber reinforced metal matrix composites:

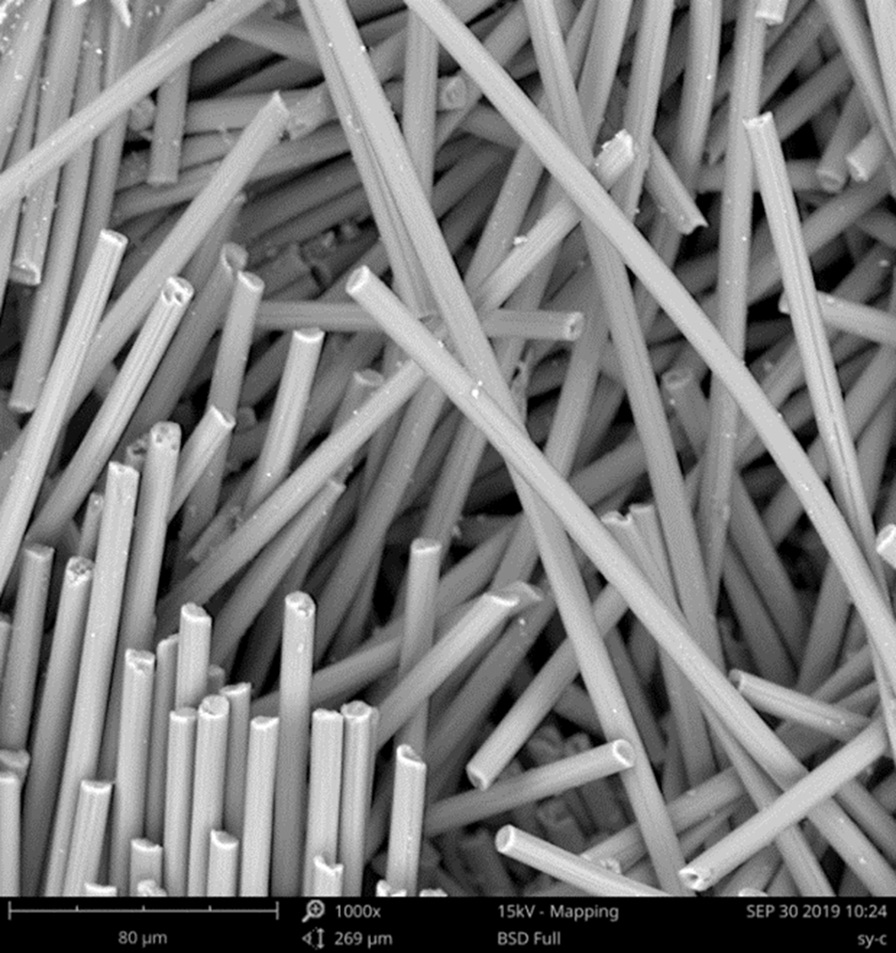

[0075] Step 1. After the continuous carbon fiber is pretreated, a layer of copper coating with a thickness of 2 μm is plated on the surface of the carbon fiber to obtain a continuous copper-coated carbon fiber. The above-mentioned continuous copper-coated carbon fiber is prepared by using the 3D printing technology. Image 6 The carbon fiber framework shown in the spatially oriented arrangement and distribution, the carbon fiber framework section is spider web-like, specifically includes the following steps:

[0076] (a) The single filament diameter of Yangzhou Carbon Fiber Engineering Technology Center is 7μm; the tow is 6K; the tensile strength is 3500MPa; the tensile modulus is 220Gpa, and the sizing rate is 0.8%. Continuous carbon fiber filaments are burned and degummed in turn , sodium hydroxide solution cleaning, nitric acid solution etching, ion water cleaning to neutrality, stan...

Embodiment 2

[0090] Step 1. After the continuous carbon fiber is pretreated according to the method of Example 1, a layer of copper coating with a thickness of 5 μm is plated on the surface of the carbon fiber to obtain a continuous copper-coated carbon fiber. The above-mentioned continuous copper-coated carbon fiber is prepared into a scroll shape by using 3D printing technology , the scroll equation is: , to obtain a scroll-shaped carbon fiber skeleton;

[0091] Step 2, preparing 200g of reduced copper powder with a size of 200 mesh;

[0092] Step 3, putting the scroll-shaped carbon fiber skeleton into a regular hexagonal cold-press mold with a side length of 27 mm, and then adding the reduced copper powder in step 2 to the cold-press mold to obtain a loose-packed embryo body;

[0093] Step 4, putting the loose-packed embryo body into a cold press molding machine for compression molding, the pressing speed is 30mm / min, the pressing pressure is 700MPa, and the holding time is 30s, so as...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com